Palm wax industrial water-saving agent and preparation method thereof

A technology of palm wax and described palm wax, which is applied in chemical instruments and methods, water/sewage treatment, special compound water treatment, etc., and can solve the problems of high energy consumption, poor convenience, and high investment in equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

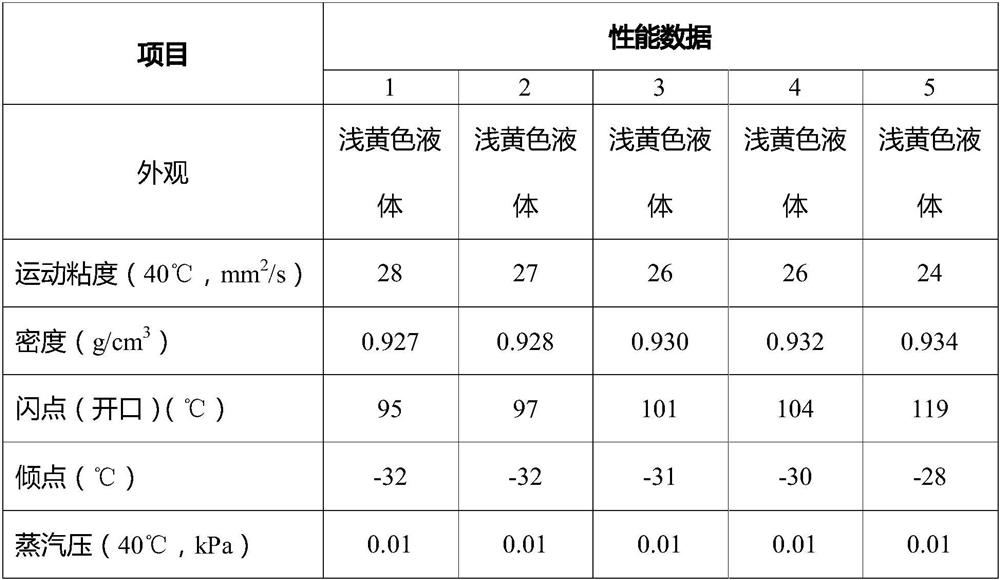

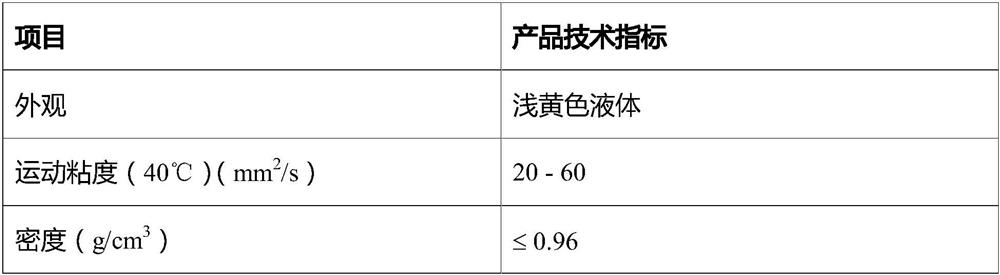

Embodiment 1

[0019] Raw materials: 100kg hexanediol and 3.13kg functional additives (including 3.0kg hydrophobic agent, 0.1kg antioxidant additive, 0.01kg bactericidal preservative and 0.02kg bactericidal antifungal agent).

[0020] Preparation steps: Take 20kg of hexanediol and add it into the mixing kettle, heat it to 60-80°C; take 3.0kg of hydrophobic agent, 0.1kg of antioxidant additive, 0.01kg of bactericidal preservative, and 0.02kg of bactericidal and antifungal agent into the mixing kettle Add the remaining 80kg of hexanediol to the mixing kettle, stir and mix evenly, put it into barrels after cooling, and seal it for storage to prepare the industrial water-saving agent.

Embodiment 2

[0022] Raw materials: 100kg hexanediol and 5.24kg functional additives (including 5.0kg hydrophobic agent, 0.2kg antioxidant additive, 0.02kg bactericidal preservative and 0.02kg bactericidal antifungal agent).

[0023] Preparation steps: Take 25kg of hexanediol and add it to the mixing kettle, heat it to 60-80°C; take 5.0kg of hydrophobic agent, 0.2kg of antioxidant additive, 0.02kg of bactericidal preservative, and 0.02kg of bactericidal and antifungal agent into the mixing kettle Add the remaining 75kg of hexanediol to the mixing kettle, stir and mix evenly, put it in barrels after cooling, and seal it for storage to obtain the industrial water-saving agent.

Embodiment 3

[0025] Raw materials: 100kg hexanediol and 8.36kg functional additives (including 8.0kg hydrophobic agent, 0.3kg antioxidant additive, 0.02kg bactericidal preservative and 0.04kg bactericidal antifungal agent).

[0026] Preparation steps: Take 30kg of hexanediol and add it to the mixing kettle, heat it to 60-80°C; successively take 8.0kg of hydrophobic agent, 0.3kg of antioxidant additive, 0.02kg of bactericidal preservative, and 0.04kg of bactericidal and antifungal agent and add it to the mixing kettle Add the remaining 70kg of hexanediol to the mixing kettle, stir and mix evenly, put it into barrels after cooling, and seal it for storage to prepare the industrial water-saving agent.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap