Method for promoting sludge dewatering through coupling of ferrous iron induced calcium peroxide and polymeric flocculant

A technology of polymer flocculant and calcium peroxide, which is applied in the direction of oxidation treatment of sludge, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve the problems of slow dehydration rate and limited degree of reduction, and achieve dehydration , obvious social and environmental benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

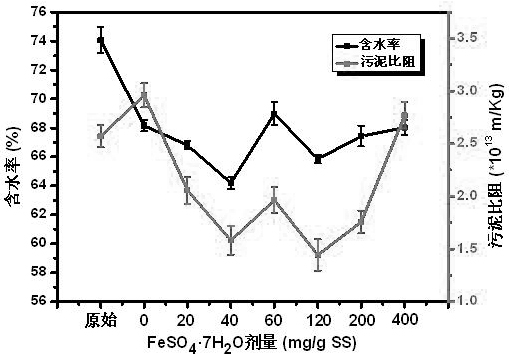

[0025] Example 1: Effect of different concentrations of ferrous iron on sludge dewatering performance

[0026] (Why there is no step of adding flocculant in the example)

[0027] Measure 100mL of activated sludge solution with a solid content of 15g / L and place them in a 250mL beaker, adjust the pH value of the sludge solution to 2.0 with a concentration of 1mol / L sulfuric acid, and then stir the reaction for 10min under the action of a magnetic stirrer , the stirring speed is 200r / min. Adding different doses of FeSO to the sludge solution in turn 4 ·7H 2 O and a fixed dose of CaO 2 , stirred for 30 minutes, and the stirring speed was 200 r / min. Finally, the conventional Buchner funnel test was used to measure the sludge specific resistance (SRF) and sludge water content to evaluate the sludge dewatering efficiency. FeSO 4 ·7H 2 The addition of O is respectively 0, 20, 40, 60, 120, 200 and 400 mg / g suspended solids based on the solid content of the activated sludge; CaO...

Embodiment 2

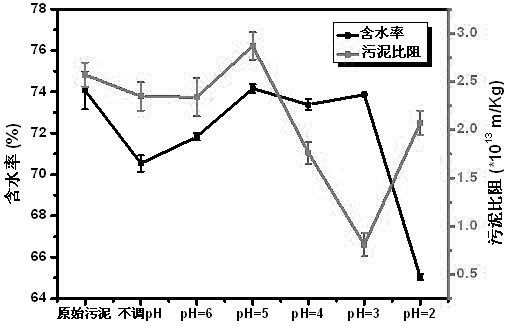

[0028] Example 2: Effect of pH value of sludge solution on sludge dewatering performance

[0029]Measure 100mL of activated sludge solution with a solid content of 15g / L and put them in a 250mL beaker, adjust the pH value of the sludge solution to 2.0, 3.0, 4.0, 5.0 and 6.0 with sulfuric acid at a concentration of 0~1mol / L , and then stirred and reacted for 10 min under the action of a magnetic stirrer, and the stirring speed was 200 r / min. A fixed dose of FeSO was sequentially added to the sludge solution 4 ·7H 2 O and CaO 2 , stirred for 30 minutes, and the stirring speed was 200 r / min. Finally, the sludge specific resistivity (SRF) and sludge water content were measured by conventional Buchner funneltest method to evaluate the sludge dewatering efficiency. FeSO 4 ·7H 2 The amount of O added is 120 mg / g suspended solids based on the activated sludge solids content; CaO 2 The added amount is 30 mg / g suspended solids based on the activated sludge solids content. figur...

Embodiment 3

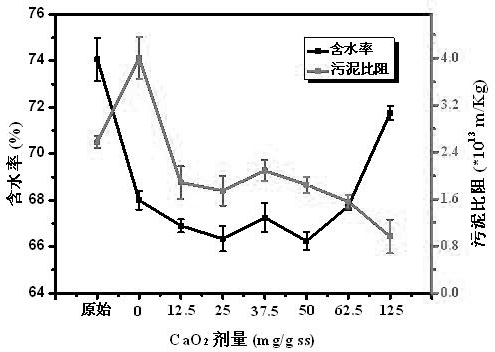

[0030] Embodiment 3: the influence of calcium peroxide of different concentrations on sludge dewatering performance

[0031] Measure 100mL of activated sludge solution with a solid content of 15g / L and place them in a 250mL beaker, adjust the pH value of the sludge solution to 2.0 with a concentration of 1mol / L sulfuric acid, and then stir the reaction for 10min under the action of a magnetic stirrer , the stirring speed is 200r / min. Add different doses of CaO to the sludge solution in sequence 2 and a fixed dose of FeSO 4 ·7H 2 O, stirring and reacting for 30min, the stirring speed was 200r / min. Finally, the conventional Buchner funnel test was used to measure the sludge specific resistance (SRF) and sludge water content to evaluate the sludge dewatering efficiency. The CaO 2 The addition amount is respectively 0, 12.5, 25, 37.5, 50, 62.5 and 125 mg / g suspended solids based on the solid content of the activated sludge; 4 ·7H 2 The amount of O added is 40 mg / g suspended...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com