Preparation process of desulfurized gypsum-based crystal-plastic composite material

A technology for desulfurization gypsum and composite materials, which is applied in the field of crystal plastic materials and can solve the problems that there is no desulfurization gypsum, records, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

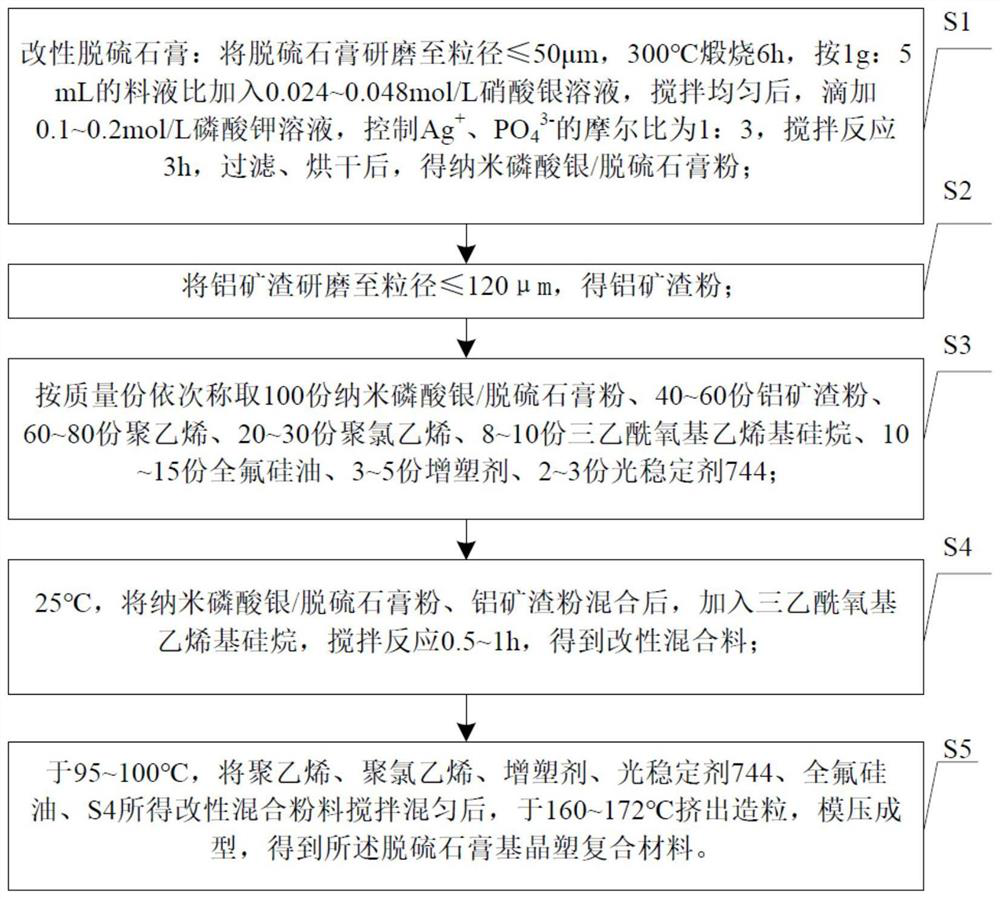

[0023] The preparation process of the desulfurized gypsum-based crystal-plastic composite material comprises the following steps:

[0024] S1: Modified desulfurized gypsum: Grind the desulfurized gypsum to a particle size of ≤50 μm, calcinate at 300°C for 6 hours, add 0.024mol / L silver nitrate solution at a solid-liquid ratio of 1g:5mL, stir well, then add 0.1mol / L phosphoric acid dropwise Potassium solution, control Ag + 、PO 4 3- The molar ratio is 1:3, stirred and reacted for 3 hours, filtered and dried to obtain nano-silver phosphate / desulfurized gypsum powder;

[0025] S2: Grinding the aluminum slag to a particle size of ≤120 μm to obtain aluminum slag powder;

[0026] S3: Weigh 100 parts of nano-silver phosphate / desulfurized gypsum powder, 40 parts of aluminum slag powder, 60 parts of polyethylene, 20 parts of polyvinyl chloride, 8 parts of triacetoxyvinylsilane, and 10 parts of perfluorosilicone oil in order by mass parts , 3 parts of dioctyl phthalate, 2 parts of li...

Embodiment 2

[0030] The preparation process of the desulfurized gypsum-based crystal-plastic composite material comprises the following steps:

[0031] S1: Modified desulfurized gypsum: Grind the desulfurized gypsum to a particle size of ≤50 μm, calcinate at 300°C for 6 hours, add 0.027mol / L silver nitrate solution at a solid-liquid ratio of 1g:5mL, stir well, then add 0.1mol / L phosphoric acid dropwise Potassium solution, control Ag + 、PO 4 3- The molar ratio is 1:3, stirred and reacted for 3 hours, filtered and dried to obtain nano-silver phosphate / desulfurized gypsum powder;

[0032] S2: Grinding the aluminum slag to a particle size of ≤120 μm to obtain aluminum slag powder;

[0033] S3: Weigh 100 parts of nano-silver phosphate / desulfurized gypsum powder, 50 parts of aluminum slag powder, 70 parts of polyethylene, 25 parts of polyvinyl chloride, 9 parts of triacetoxyvinylsilane, and 12.5 parts of perfluorosilicone oil in order by mass parts , 4 parts of dibutyl phthalate, 2.5 parts o...

Embodiment 3

[0037] The preparation process of the desulfurized gypsum-based crystal-plastic composite material comprises the following steps:

[0038] S1: Modified desulfurized gypsum: Grind the desulfurized gypsum to a particle size of ≤50 μm, calcinate at 300°C for 6 hours, add 0.036mol / L silver nitrate solution at a solid-liquid ratio of 1g:5mL, stir well, then add 0.15mol / L phosphoric acid dropwise Potassium solution, control Ag + 、PO 4 3- The molar ratio is 1:3, stirred and reacted for 3 hours, filtered and dried to obtain nano-silver phosphate / desulfurized gypsum powder;

[0039] S2: Grinding the aluminum slag to a particle size of ≤120 μm to obtain aluminum slag powder;

[0040] S3: Weigh 100 parts of nano-silver phosphate / desulfurized gypsum powder, 55 parts of aluminum slag powder, 70 parts of polyethylene, 25 parts of polyvinyl chloride, 9 parts of triacetoxyvinylsilane, and 13 parts of perfluorosilicone oil according to parts by mass , 4 parts of tricresyl phosphate, 2.5 pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com