Metamaterial terahertz biosensor and production method thereof

A biosensor, terahertz technology, applied in the field of sensors, can solve the problems of low absorption rate, weakened energy, weakened resonance strength, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

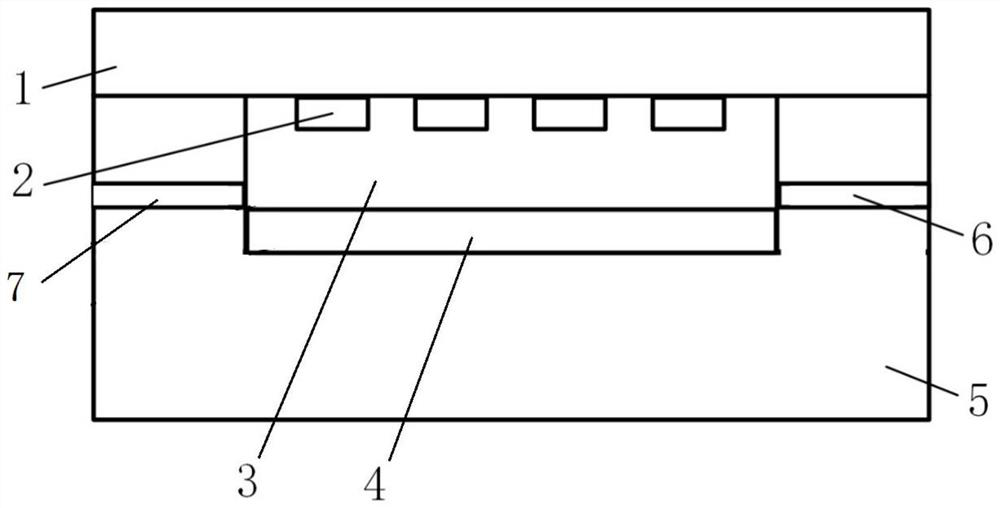

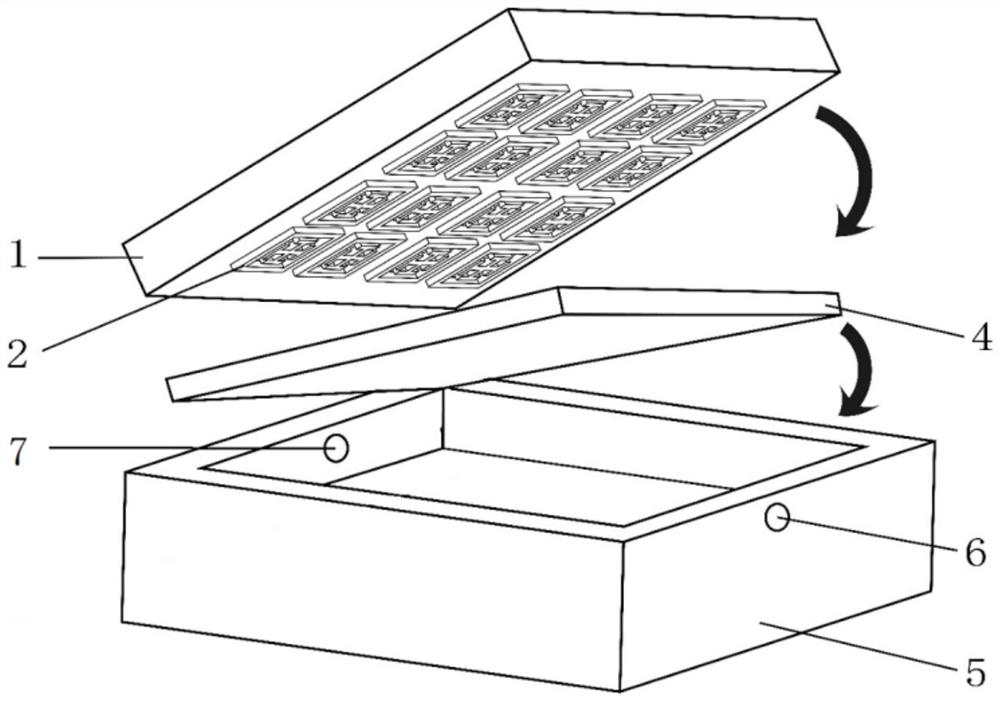

[0047] The preparation method of the above-mentioned metamaterial terahertz biosensor comprises the following steps:

[0048] 1) Preparation of the top layer module: on the dielectric layer 1, the metal microstructure layer 2 is formed on the dielectric layer 1 through the processes of gluing, exposure, development, coating, and stripping to obtain the top layer module;

[0049] 2) Preparation of the bottom module: Etch on the base layer 5 to form a groove matching the size of the top module, then layer a metal film on the bottom surface of the groove to form a metal reflective layer 4, and finally open a groove on the base layer 5 The liquid inlet 7 and the liquid outlet 6 connected by the groove obtain the bottom module;

[0050] 3) Bonding the top module and the bottom module, forming a microfluidic channel 3 between the metal microstructure layer 2 of the top module and the metal reflection layer 4 of the bottom module, to obtain the metamaterial terahertz biosensor.

[0...

Embodiment 1

[0056] by Figure 1 to Figure 3 The structure diagram shown illustrates the structure and preparation of the sensor of the present invention.

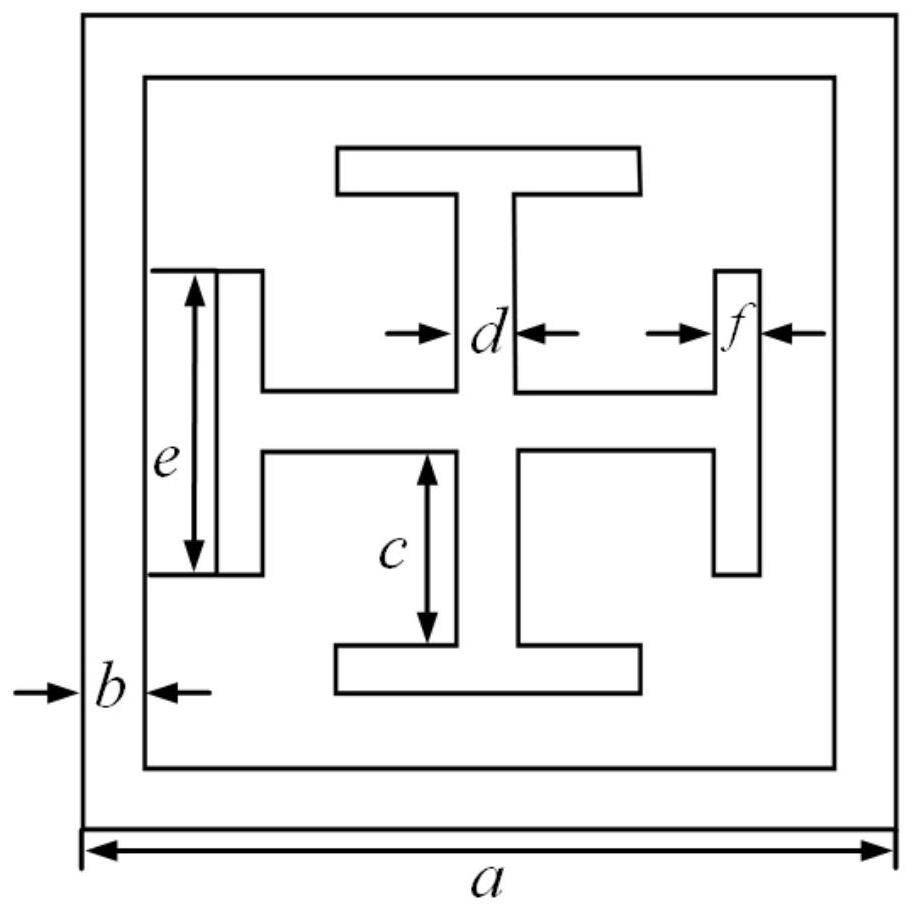

[0057] see Figure 1 to Figure 3 , the metal microstructure layer 2 is 4╳4 units periodically arranged on the dielectric layer 1, and the period of the metal microstructure layer 2 in the X-axis direction and the period in the Y-axis direction are both 120 μm. In the structure of the metal microstructure layer 2, the outer length a of the square metal ring is 108 μm, and the ring width b is 8 μm; the arm length c of the “H” metal ring in the double “H” cross metal structure is 26 μm, and the arm width d is 8 μm, the leaf length e is 40 μm, and the leaf width f is 6 μm.

[0058] The thickness of the base layer 5 is 110 μm, and its material is high resistance silicon; the thickness of the dielectric layer 1 is 6 μm, and its material is polytetrafluoroethylene; the thickness of the metal microstructure layer 2 is 0.2 μm, and its materia...

Embodiment 2

[0074] by Figure 7 The sensor structure unit of the structure shown analyzes the absorption characteristics of the sensor.

[0075] exist Figure 7 In the shown sensor structure unit, the period (Dx) of the metal microstructure layer 2 in the X-axis direction and the period (Dy) in the Y-axis direction are both 120 μm. In the structure of the metal microstructure layer 2, the outer length a of the square metal ring is 108 μm, and the ring width b is 8 μm; the arm length c of the “H” metal ring in the double “H” cross metal structure is 26 μm, and the arm width d is 8 μm, the leaf length e is 40 μm, and the leaf width f is 6 μm. The thickness of the base layer 5 is 110 μm, and its material is high-resistance silicon; the thickness of the dielectric layer 1 is 6 μm, and its material is polytetrafluoroethylene; the thickness of the metal microstructure layer 2 is 0.2 μm, and its material is silver; The reflective layer 4 has a thickness of 0.2 μm and its material is silver; t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Arm length | aaaaa | aaaaa |

| Arm width | aaaaa | aaaaa |

| Ye chang | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com