Bimetal organic framework nanosheet and application thereof in supercapacitor

An organic framework and nanosheet technology, which is applied in the field of cobalt-containing ultra-thin bimetallic organic framework nanosheets and its preparation, can solve problems such as poor repeatability, insufficient stability of nanosheets, and difficult controllable synthesis of MOF nanosheets.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Example 1 Preparation of bimetallic organic framework nanosheets

[0030] (1) Weigh 1 mmol Co(NO 3 ) 2 ·6H 2 O and 0.05 mmol M(NO 3 ) 2 ·nH 2 O (M is Mn, Zn, Cu, Ni) was dissolved in 30 mL of N,N-dimethylformamide and water (the volume ratio of the two was 1:1) and stirred by a magnetic stirrer After 15 minutes, the mixed reaction solution 1 was prepared.

[0031] (2) Weigh 4 mmol of 2-methylimidazole and dissolve in 30 mL of N, N-dimethylformamide and water (the volume ratio of the two is 1:1) mixed solution, and stir for 15 min with a magnetic stirrer , to prepare the mixed reaction solution 2.

[0032] (3) The mixed reaction solution 1 was poured into the mixed reaction solution 2 at one time, and stirred by a magnetic stirrer at room temperature for 24 hours to obtain the precipitate formed by the reaction.

[0033] (4) The precipitate was collected by centrifugation, washed with deionized water and ethanol, and then dried or dispersed in an ethanol solvent ...

Embodiment 2

[0036] Example 2 Preparation of electrode materials

[0037] Mix 85% bimetallic organic framework nanosheets and 15% acetylene black, and grind for 30 minutes, then add a few drops of isopropanol and grind for 15 minutes, add 1 drop of PTFE, and grind to form a slurry. 1.2 mg of this slurry was coated on nickel foam, and pressed at 5 kPa to obtain a working electrode.

Embodiment 3

[0038] Example 3 Electrochemical performance test.

[0039]A Hg / HgO electrode with 3.0 M KOH electrolyte and a platinum wire were used as the reference electrode and the counter electrode, respectively. Cyclic voltammetry, galvanostatic charge-discharge and electrochemical impedance spectroscopy were tested by electrochemical workstation CHI760E in 3.0 M KOH aqueous solution.

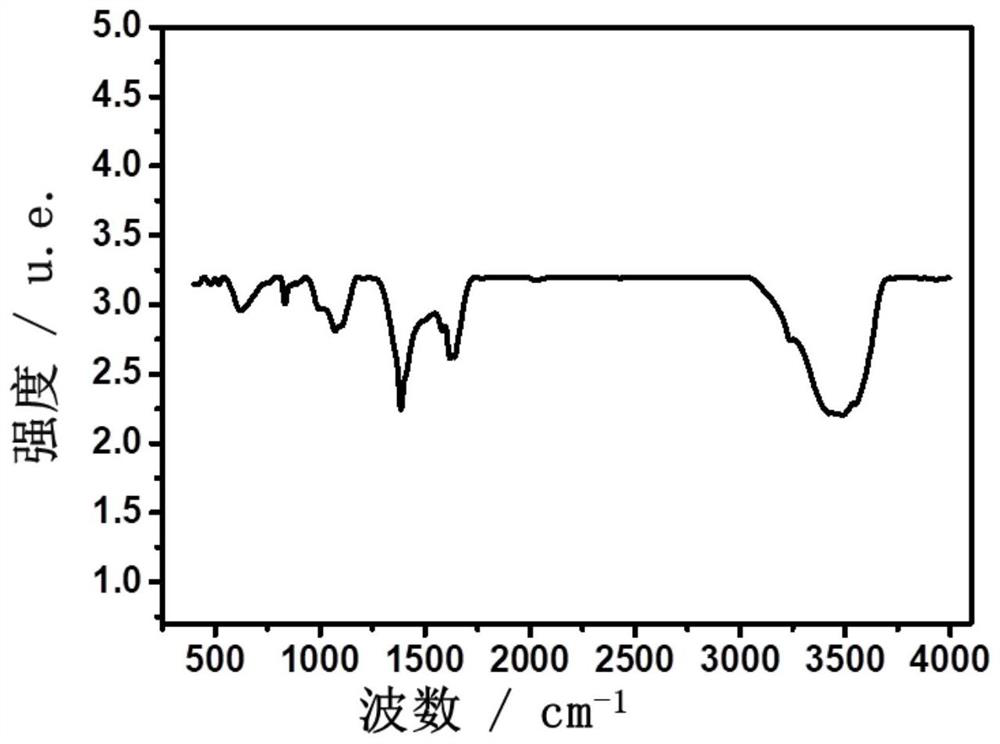

[0040] figure 1 It is the Fourier transform infrared (FT-IR) picture of the CoZn-MOF synthesized by the present invention. Strong and broad peak at 3250-3500cm -1 can be attributed to H 2 O-OH stretching vibration mode, at 1600-1700cm -1 The absorption peak of is regarded as the stretching vibration peak of C=C, and the FT-IR figure indirectly illustrates the successful synthesis of MOF materials.

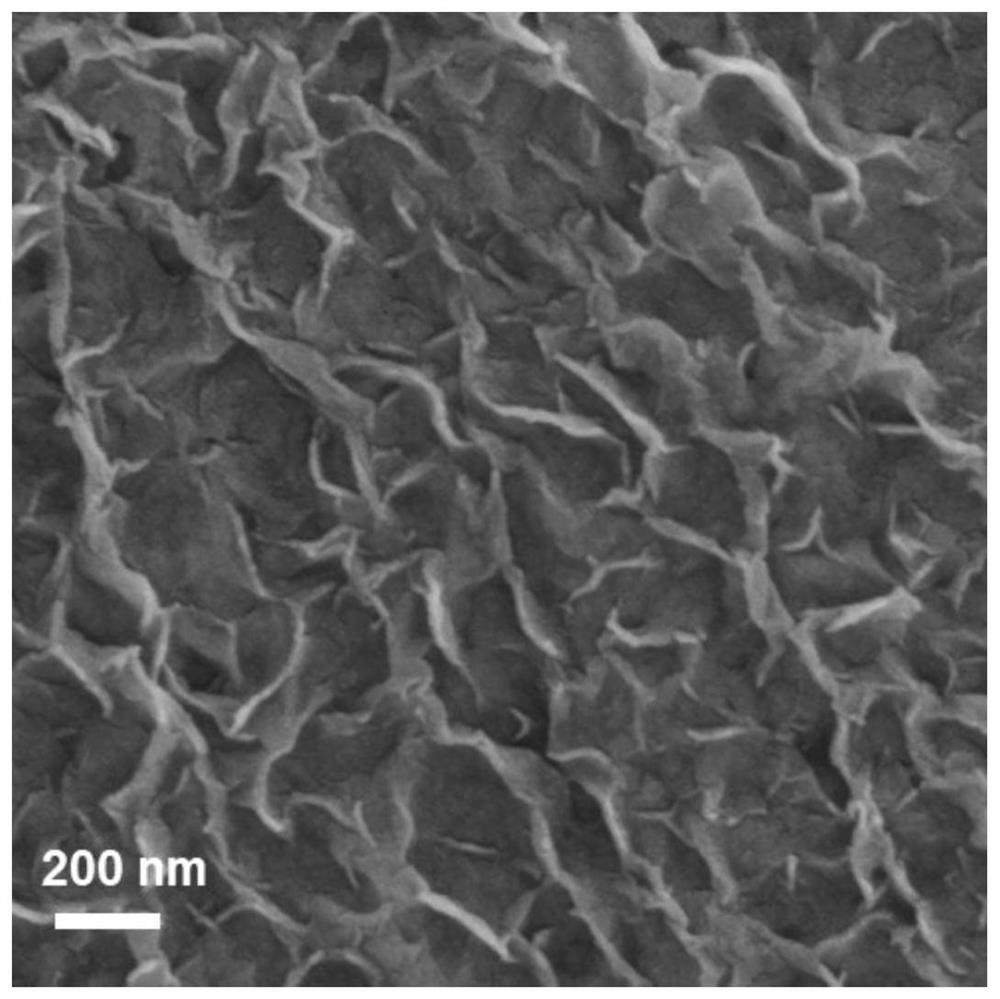

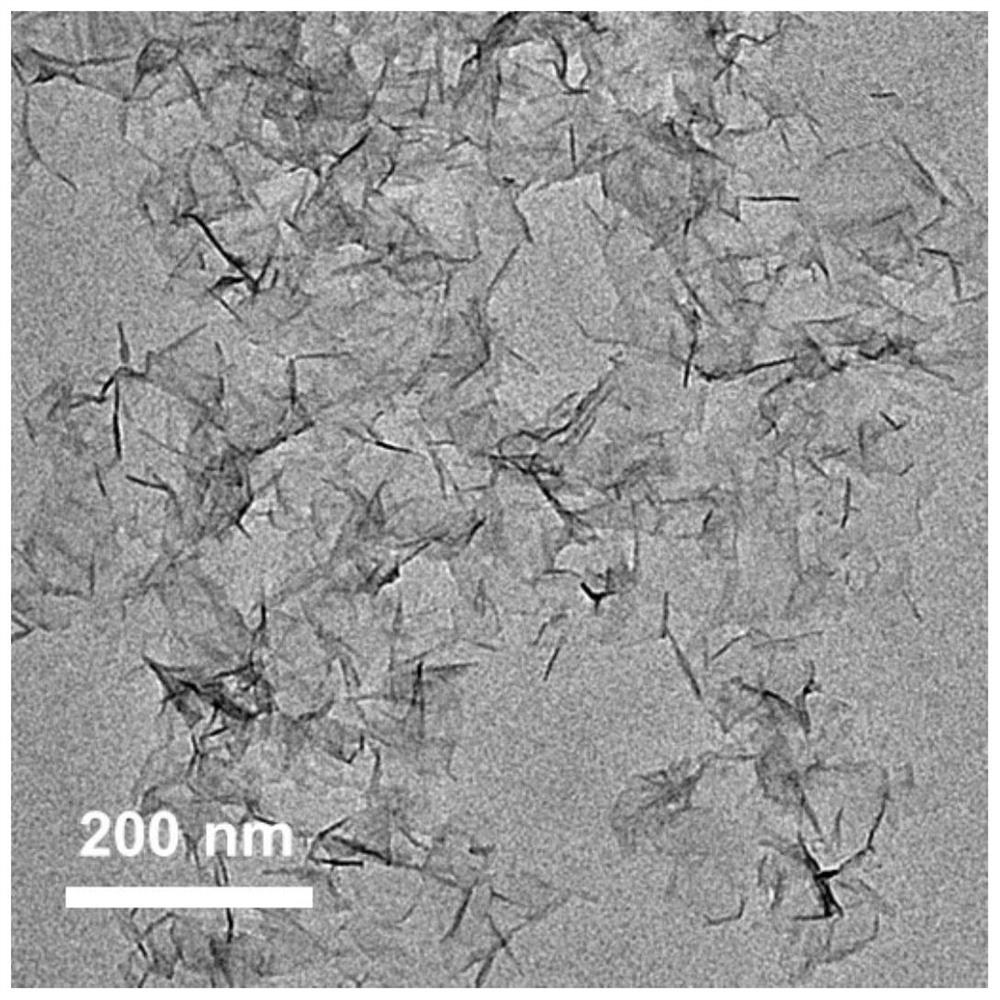

[0041] figure 2 It is the scanning electron microscope (SEM) picture of the CoMn-MOF synthesized by the present invention. SEM images show that the synthesized CoMn-MOFs are all sheet-like structures...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com