Pt nanoparticle loaded molybdenum dioxide/nickel hydroxide nanosheet array structure material, preparation method and application thereof

A nanosheet array and nanoparticle technology, applied in metal/metal oxide/metal hydroxide catalysts, catalyst activation/preparation, chemical instruments and methods, etc., can solve the problem of uniform deposition, non-elimination or reduction of Pt nanoparticles Schottky barrier and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

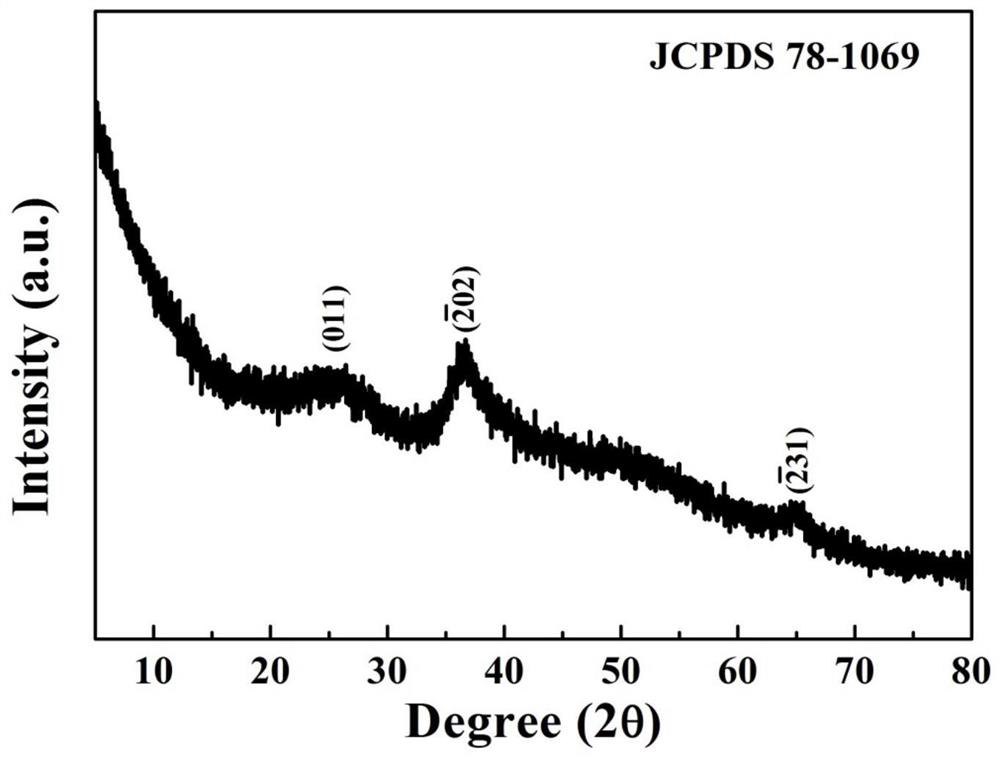

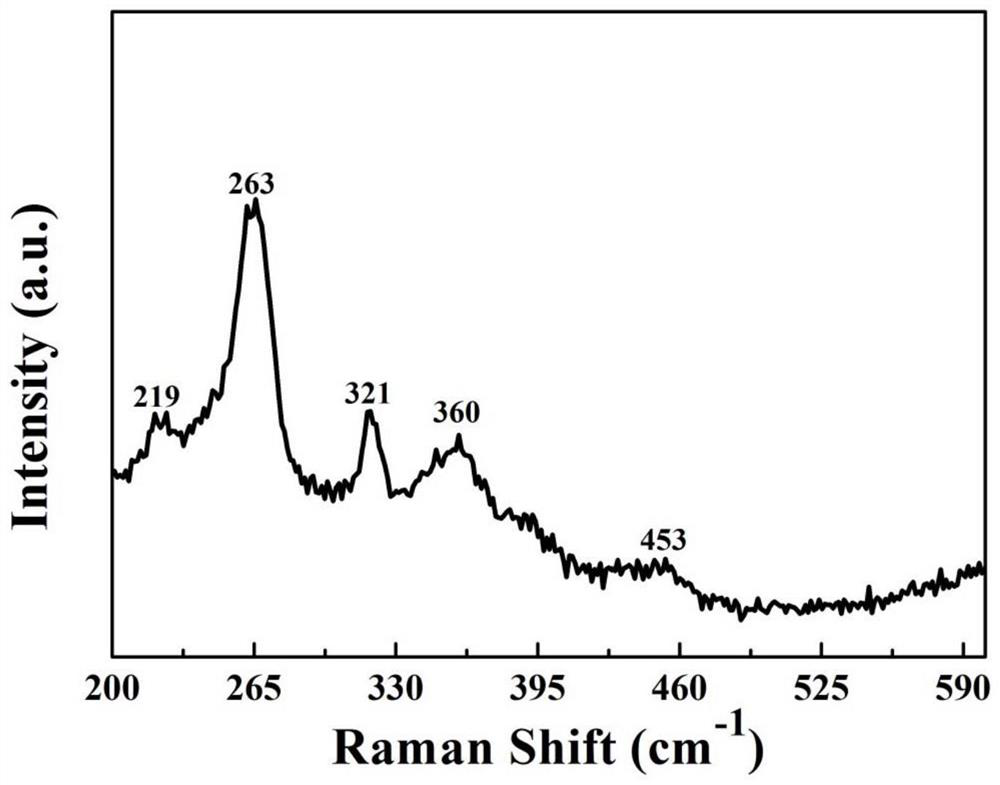

[0046] A kind of Pt nanoparticles loaded with MoO 2 / Ni(OH) 2 The preparation method of the nanosheet array material includes the following steps:

[0047] Soak 2×3cm foam nickel in 6M hydrochloric acid solution for 15 minutes, and wash foam nickel 3 times with deionized water and absolute ethanol;

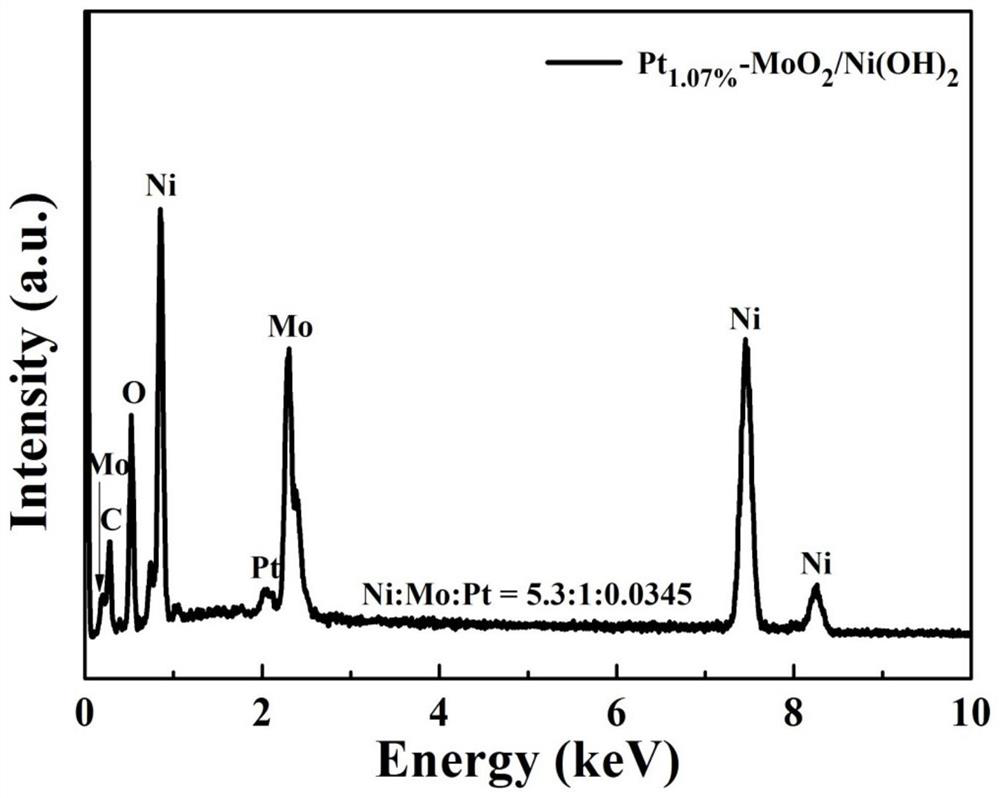

[0048] Accurately measure 30mL ammonia water into a 50mL clean small beaker, and then add 1.4mmol Ni(NO 3 ) 2 ·6H 2 O, 0.35mmol(NH 4 ) 6 Mo 7 O 24 ·4H 2 O, 0.05mL H with a concentration of 0.03M 2 PtCl 6 Solution and 2mmol NaBH 4 After stirring for 10 min, add 10 mL of anhydrous methanol. After stirring for 5 minutes, add 0.35mL of 0.03M H 2 PtCl 6 Solution, continue to stir for 1-2 min to obtain a homogeneous solution;

[0049] Transfer the solution to a 50mL polytetrafluoroethylene-lined stainless steel reactor, put the clean foamed nickel into the solution obliquely, seal and react in a 150℃ oven for 8h. After the reaction is over, cool to room temperature naturally and cover The foa...

Embodiment 2

[0059] Pt nanoparticles loaded with MoO 2 / Ni(OH) 2 The preparation method of the nanosheet array material includes the following steps:

[0060] Soak 2×3cm foam nickel in 6M hydrochloric acid solution for 15 minutes, and wash foam nickel 3 times with deionized water and absolute ethanol;

[0061] Accurately measure 30mL ammonia water into a 50mL clean small beaker, add 1.4mmol Ni(NO 3 ) 2 ·6H 2 O, 0.35mmol(NH 4 ) 6 Mo 7 O 24 ·4H 2 O, 0.05mL H with a concentration of 0.03M 2 PtCl 6 Solution and 2mmol NaBH 4 After stirring for 10 min, add 10 mL of anhydrous methanol. After stirring for 5 minutes, add 0.25mL or 0.45mL of 0.03M H 2 PtCl 6 Solution, continue to stir for 1-2 min to obtain a homogeneous solution;

[0062] Transfer the solution to a 50mL polytetrafluoroethylene-lined stainless steel reactor, put the clean foamed nickel into the solution obliquely, seal and react in a 150℃ oven for 8h. After the reaction is over, cool to room temperature naturally and cover The nickel foam ...

Embodiment 3

[0067] A kind of Pt nanoparticles loaded with MoO 2 / Ni(OH) 2 Application of nanosheet materials as hydrogen evolution reaction (HER) catalyst.

[0068] The specific application method is: load MoO on the Pt nanoparticles obtained in each embodiment with an area of 0.5×0.5cm. 2 / Ni(OH) 2 The nanosheet material is used as the working electrode, the carbon rod is used as the counter electrode, the Ag / AgCl electrode is used as the reference electrode, and the CHI 760E electrochemical workstation is used for testing in 1.0M KOH electrolyte solution. Using linear sweep voltammetry (LSV) at 5.0mV·s -1 The polarization curve is obtained at the scanning rate of 90% and the ohmic compensation is 90%, and the polarization curve is obtained with Pt / C, MoO 2 / Ni(OH) 2 Nanosheet material (MoO 2 / Ni(OH) 2 The preparation of the nanosheet material is compared with the preparation method in Example 1, omitting the chloroplatinic acid solution in the raw material) as a working electrode for compa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Horizontal size | aaaaa | aaaaa |

| Average size | aaaaa | aaaaa |

| Interplanar spacing | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com