Silk fibroin 3D printing based biological scaffold and preparation method and application thereof

A silk fibroin, 3D printing technology, applied in 3D object support structures, additive manufacturing, manufacturing tools, etc., can solve problems such as affecting 3D printing, high printer equipment requirements, and difficult curing and molding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Embodiment 1 prepares silk fibroin solution and HPMC solution

[0052] Put silkworm cocoons in Na 2 CO 3 (0.5wt%) solution boiled for 45min, and then repeatedly washed with deionized water; put the silk in a 40°C oven to dry overnight; put the degummed silk into a LiBr (9.3mol / L) solution at 60°C, and heat for 1h ; Then filter the dissolved silk fibroin solution with gauze; pour the silk fibroin solution into a dialysis bag (molecular weight cut-off 14,000Da), dialyze with deionized water for 3 days, change the water 3-4 times a day, to remove LiBr in the solution Centrifuge the dialyzed silk fibroin solution (8000rpm, 8min), then filter the supernatant with gauze; calibrate the concentration of the silk fibroin to 4wt% by weighing method; concentrate with about 20-22% PEG (PEG20000) Silk fibroin solution, concentrate the silk fibroin solution to a concentration of about 33-34wt%; after concentrating for 16-18 hours, slowly collect the concentrated silk protein soluti...

Embodiment 2

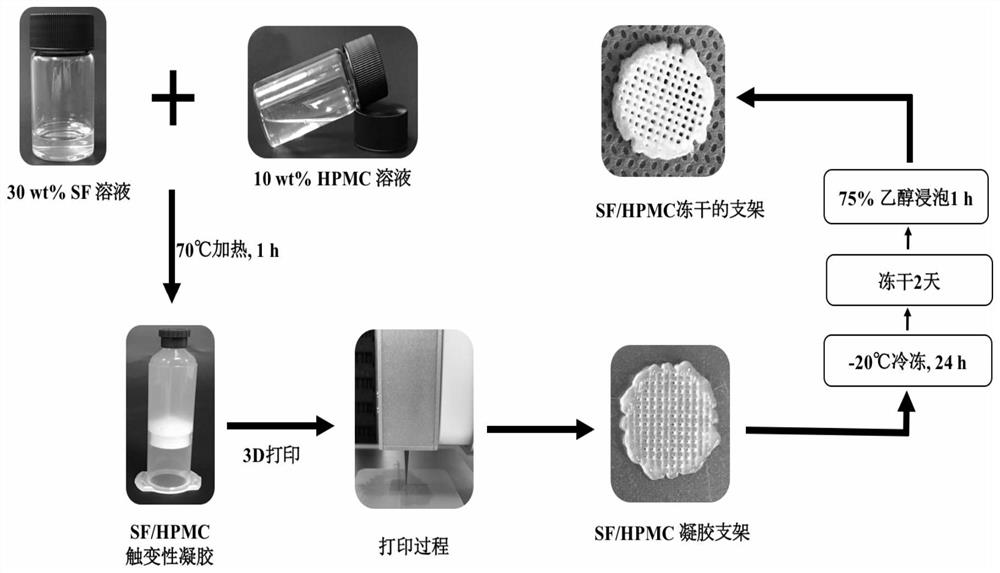

[0053] The preparation of embodiment 2SF / HPMC gel

[0054] For 3D printing materials, suitable material viscosity plays an important role in 3D printing. On the one hand, it can enable the material to be extruded from the printer nozzle, and on the other hand, it can maintain the shape of the extruded filament; If the needle is blocked, the printing will be interrupted, and too low viscosity will make the material more difficult to form; this embodiment uses Na 2 CO 3 The silk fibroin solution is prepared by degumming, and the silk fibroin solution obtained by this method has a lower molecular weight and a lower viscosity; the silk fibroin can be molded at a concentration of 15-33 wt%, and the higher the concentration, the better the moldability;

[0055] The above-mentioned concentrated silk fibroin solution is diluted to 30wt% with deionized water (this solution can be diluted to the required concentration according to actual conditions), and then 10wt% HPMC is added in the...

Embodiment 3

[0056] Example 3 Preparation of 3D printed SF / HPMC scaffold

[0057] Import the pre-designed model file whose output format is STL into the 3D printer control software; put the barrel containing 30wt% SF / HPMC thixotropic gel into the nozzle of the printer, and set the printing parameters: needle diameter 0.11-0.51 mm, printing air pressure 0.1-0.5MPa, printing speed 15-60mm s -1 ;When the gel is ejected from the nozzle, it forms a rod-like filament, and the nozzle of the printer moves along the XY axis on the printing platform. After the first layer is printed, the nozzle of the printer moves up along the Y axis to print the second layer. This is repeated layer by layer, and finally the designed model is printed; then the printed 30wt% SF / HPMC gel scaffold is frozen in a -20°C refrigerator for 24 hours, and then freeze-dried in a freeze dryer for 2 days, and finally the freeze-dried The 30wt% SF / HPMC scaffolds were soaked in 75% ethanol for 1h to induce the SF / HPMC scaffolds ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com