Graphene anticorrosive coating and preparation method thereof

An anti-corrosion coating, graphene technology, applied in anti-corrosion coatings, polyurea/polyurethane coatings, coatings, etc., can solve problems such as poor anti-corrosion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

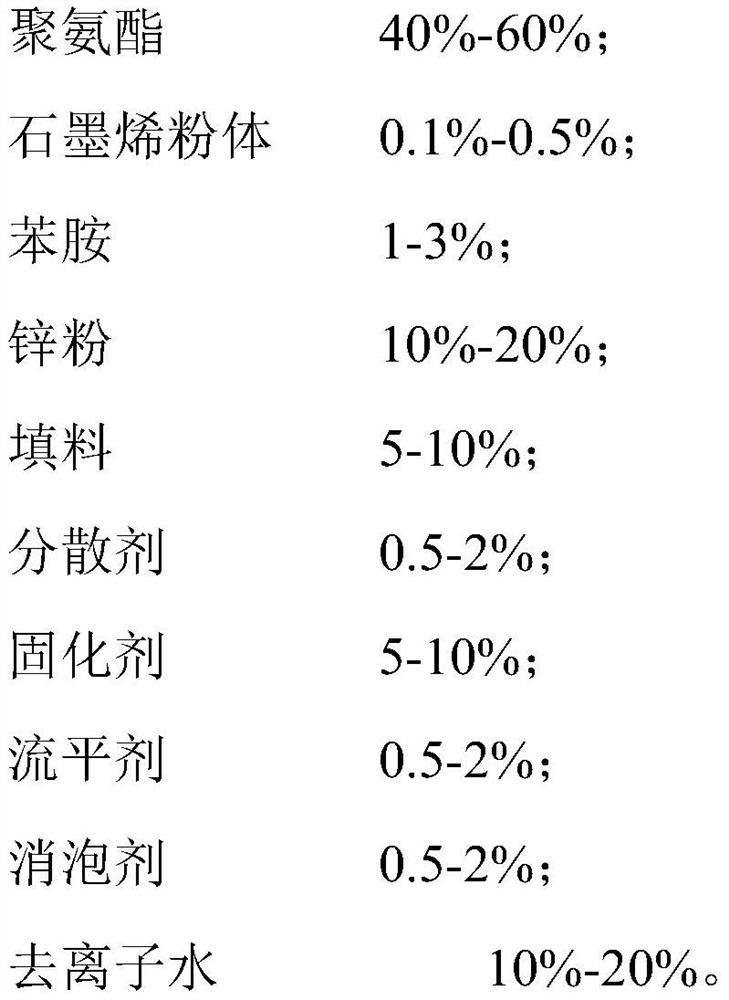

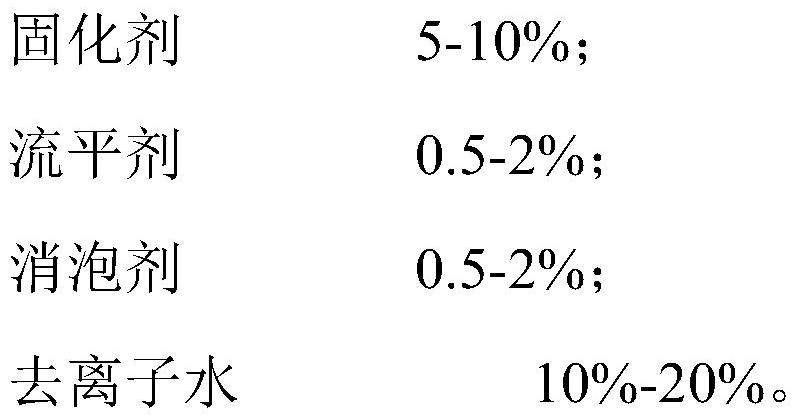

[0028] The preparation method of the above-mentioned graphene anticorrosive coating includes the following steps:

[0029] S1. Add graphene powder to the hydrochloric acid solution and place it in an ultrasonic disperser for ultrasonic dispersion for 1-2 hours. After the dispersion is uniform, add aniline, stir and mix well at 0-5°C to obtain a mixed solution; dissolve the oxidant Into the hydrochloric acid solution, and add the oxidant hydrochloric acid solution to the mixed solution, stir and mix evenly at 0-5°C, then add zinc powder, react for 3-5 hours, centrifuge and wash, to obtain the graphene / zinc / polyaniline composite material ;

[0030] S2. After mixing polyurethane, filler, dispersant, defoaming agent and part of deionized water, add leveling agent and stir evenly to obtain mixed solution A;

[0031] S3. Heat the modified polyamide curing agent in an oven to 90°C, keep it for 10-30 minutes, and then add the remaining deionized water, stir and mix uniformly, to obtain a mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com