Method for controllably synthesizing vanadium phosphorus oxide catalyst by binary mixed solvent system

A synthesis method and binary mixing technology, applied in the field of materials, can solve the problems of difficult generation of unknown phases, slow synthesis rate, fast synthesis rate, etc., and achieve the effect of appropriate synthesis rate, low cost and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

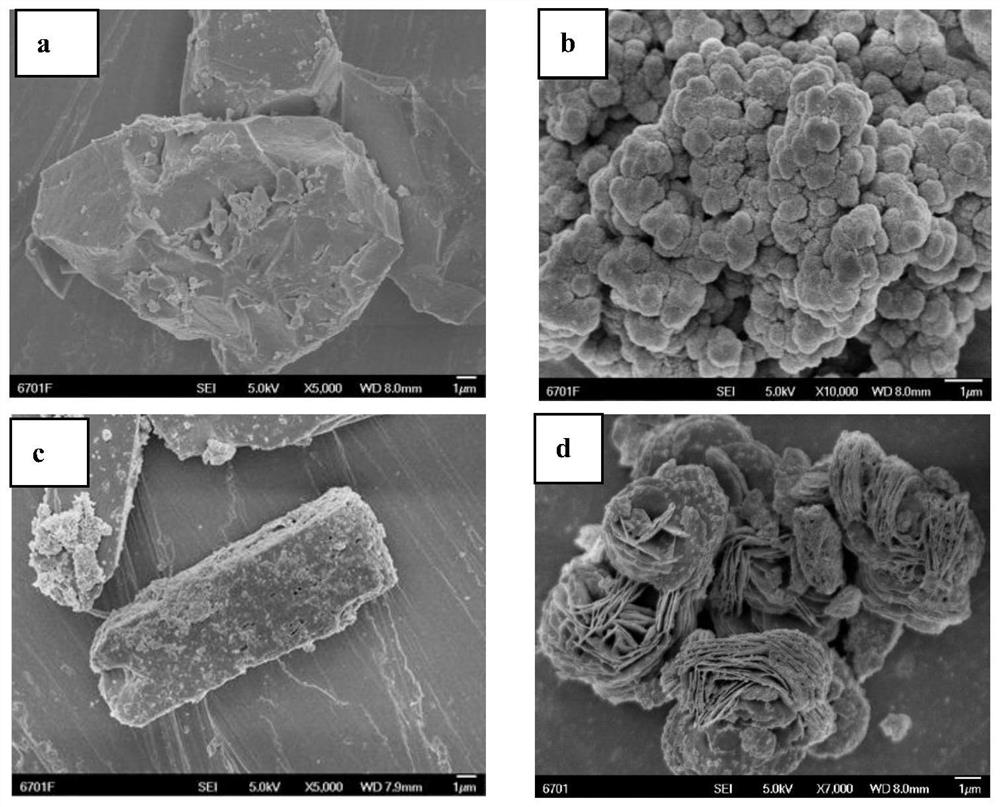

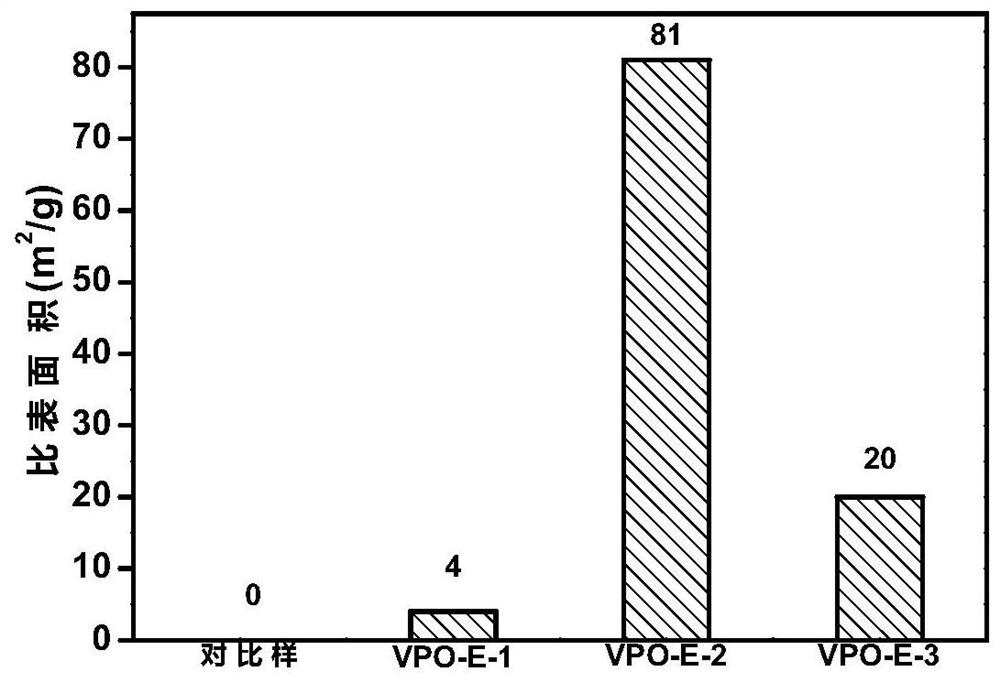

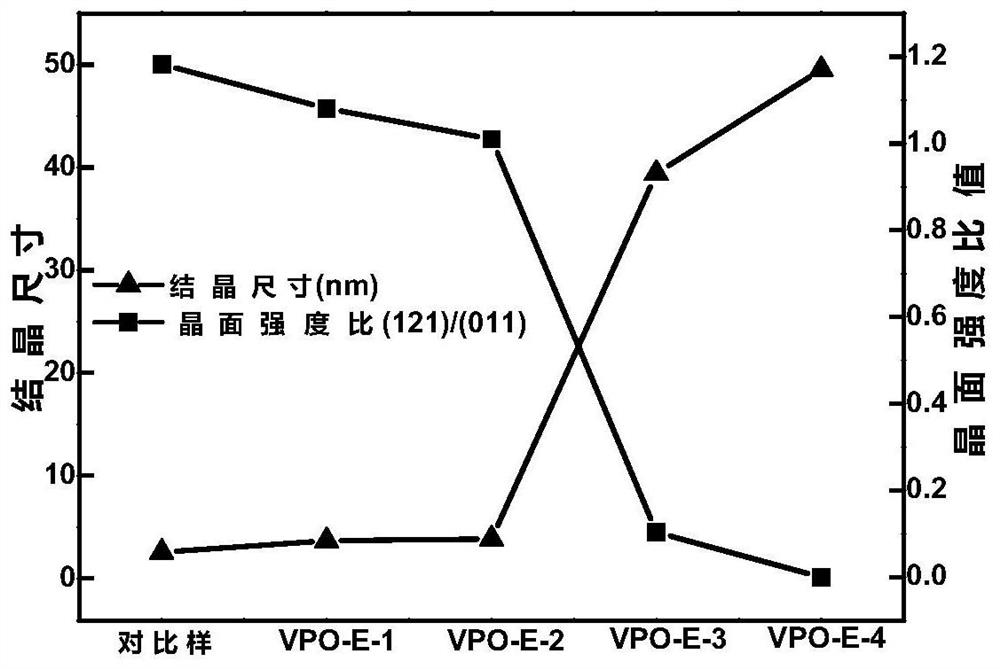

[0021] Reaction: in 250ml there-necked flask, add choline chloride (40.96g) and urea (35.32g), melt at 80 ℃, make eutectic mixture, add water 10ml subsequently, stir well, make eutectic mixture and Mixed solution of water (the mass fraction of eutectic mixture is 88%), continue to add 40.58g 85% phosphoric acid, ammonium metavanadate 5.15g, ammonium fluoride 1.14g, heat up to 100 ℃ and react for 24h, wash with water and ethanol, A blue-green solid was obtained by filtration.

[0022] Post-treatment: drying at 110°C, and air calcination at 460°C for 5 hours to obtain a vanadium phosphorus oxygen catalyst (referred to as VPO-E-1).

Embodiment 2

[0024] Reaction: in 250ml there-necked flask, add choline chloride (40.96g) and urea (35.32g), melt at 80 ℃, make eutectic mixture, add water 20ml subsequently, stir, make eutectic mixture and Mixed solution of water (mass fraction of eutectic mixture is 79%), continue to add 40.58g 85% phosphoric acid, ammonium metavanadate 5.15g, ammonium fluoride 1.14g, heat up to 100 ℃ and react for 24h, wash with water and ethanol, A blue-green solid was obtained by filtration.

[0025] Post-treatment: drying at 110°C, air calcination at 460°C for 5 hours, to obtain a vanadium phosphorus oxygen catalyst (referred to as VPO-E-2).

Embodiment 3

[0027] Reaction: in 250ml there-necked flask, add choline chloride (40.96g) and urea (35.32g), melt at 80 ℃, make eutectic mixture, add water 30ml subsequently, stir well, make eutectic mixture and Mixed solution of water (mass fraction of eutectic mixture is 72%), continue to add 40.58g 85% phosphoric acid, ammonium metavanadate 5.15g, ammonium fluoride 1.14g, heat up to 100 ℃ and react for 24h, wash with water and ethanol, A blue-green solid was obtained by filtration.

[0028] Post-treatment: drying at 110°C, air calcination at 460°C for 5 hours, to obtain a vanadium phosphorus oxygen catalyst (referred to as VPO-E-3).

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com