Method for preparing high-performance Nb521 product by low-cost printing

A high-performance, low-cost technology, applied in the field of powder metallurgy, which can solve the problems of low yield of spherical powder, high price of spherical niobium and niobium alloy powder, and high fluidity requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] 1. The raw material powder is hydrogenated dehydrogenated Nb521 alloy powder with a median diameter of 30 μm. The raw material Nb521 alloy powder is placed in a fluidized reaction equipment, the mass is 500g, and nitrogen or argon is filled as protective gas and fluidizing gas. After processing, a nearly spherical Nb521 alloy powder with a median diameter of 35.2μm is obtained. The fluidity is 30.8s / 50g.

[0025] 2. The nearly spherical Nb521 alloy powder obtained above has an oxygen content of 1800 ppm and a carbon content of 600 ppm.

[0026] 3. After the above treatment, the nearly spherical Nb521 alloy powder with a median diameter of 35.2 μm can be directly used for 3D printing.

[0027] 4. The nearly spherical Nb521 alloy powder 3D printed parts obtained in the present invention have a density of 98.6%, a tensile strength of 630MPa or more, and an elongation after fracture can reach 19.3%, and their mechanical properties are better than traditional fused-cast Nb521 prod...

Embodiment 2

[0029] 1. The raw material powder is hydrogenated dehydrogenated Nb521 alloy powder with a median diameter of 15 μm. The raw material Nb521 alloy powder is placed in a fluidized reaction equipment, the mass is 500g, and nitrogen or argon is filled as protective gas and fluidizing gas. After processing, a nearly spherical Nb521 alloy powder with a median diameter of 18.6 μm is obtained. The fluidity is 34.6s / 50g, oxygen content is 1900ppm, carbon content is 1150ppm, it can be directly used for 3D printing.

[0030] 2. Further, the tensile strength of the article obtained by the above 3D printing can reach 685MPa, and the elongation after fracture can reach 18.6%.

[0031] 3. The nearly spherical Nb521 alloy powder obtained above has an oxygen content of 1950 ppm and a carbon content of 600 ppm.

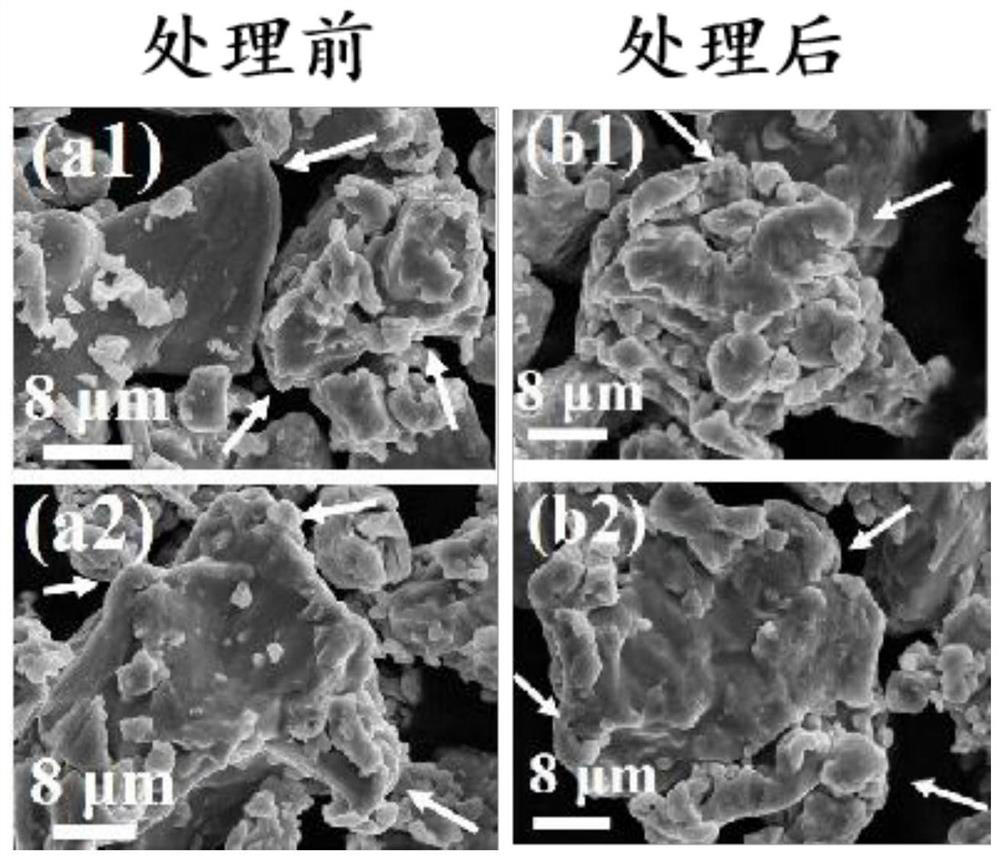

[0032] 4. The SEM morphology photos of Nb521 powder before and after fluidization treatment are as follows: figure 1 Shown.

Embodiment 3

[0034] 1. The raw material powder is hydrogenated dehydrogenated Nb521 alloy powder with a median diameter of 34μm. The raw material Nb521 alloy powder is placed in a fluidized reaction equipment, the mass is 300g, and nitrogen or argon is filled as protective gas and fluidizing gas. After processing, a nearly spherical Nb521 alloy powder with a median diameter of 38.3μm is obtained. The fluidity is 30.4s / 50g, oxygen content is 1560ppm, carbon content is 500ppm, it can be directly used for 3D printing.

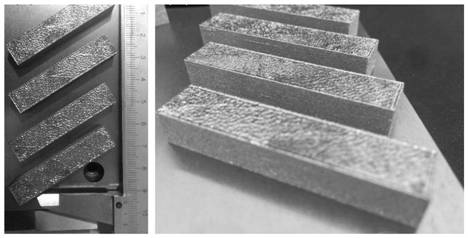

[0035] 2. Laser selective melting and forming: The substrate material is Nb521 alloy, the substrate is preheated at 200°C, the laser power is 380W, the scanning rate is 900mm / s, and the processing layer thickness is 50μm. The formed part is subjected to sandblasting treatment, and then ultrasonically cleaned for 10 minutes and then dried to obtain a Nb521 alloy 3D printed part.

[0036] 3. After testing, the density of the part is 98.8%, the oxygen content is 1620ppm, the tensile ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Fluidity | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com