Metal-phase molybdenum disulfide, self-supporting electrode, preparation methods and application

A self-supporting electrode, molybdenum disulfide technology, applied in the field of materials, can solve the problems of low safety and long preparation period

- Summary

- Abstract

- Description

- Claims

- Application Information

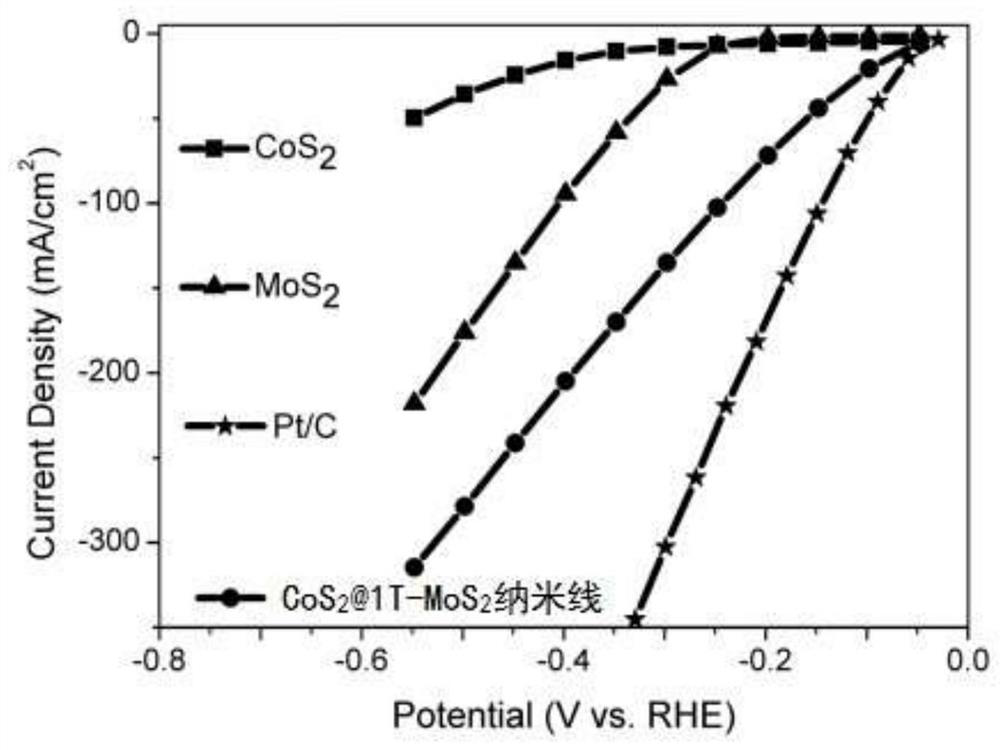

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

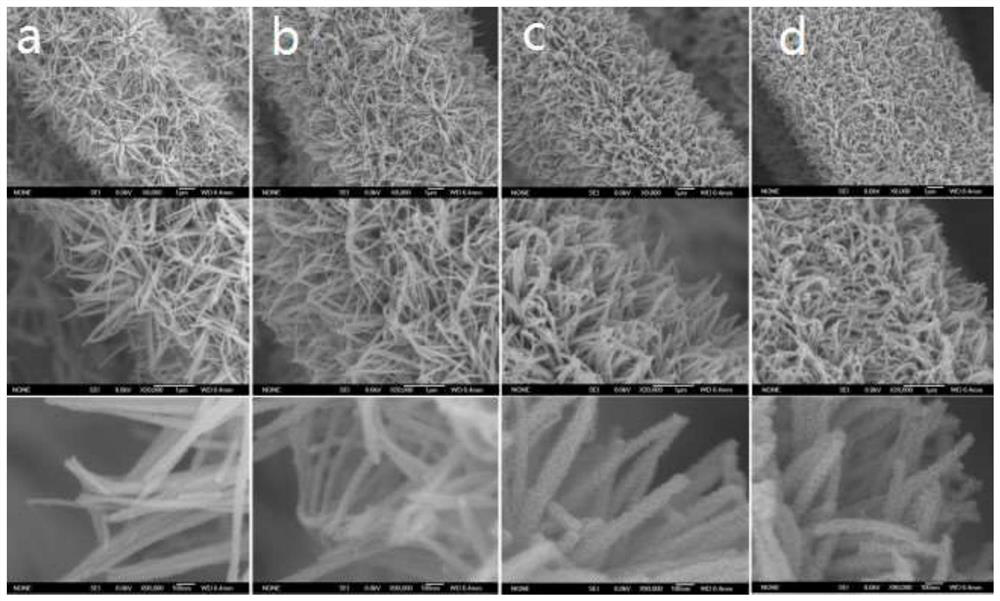

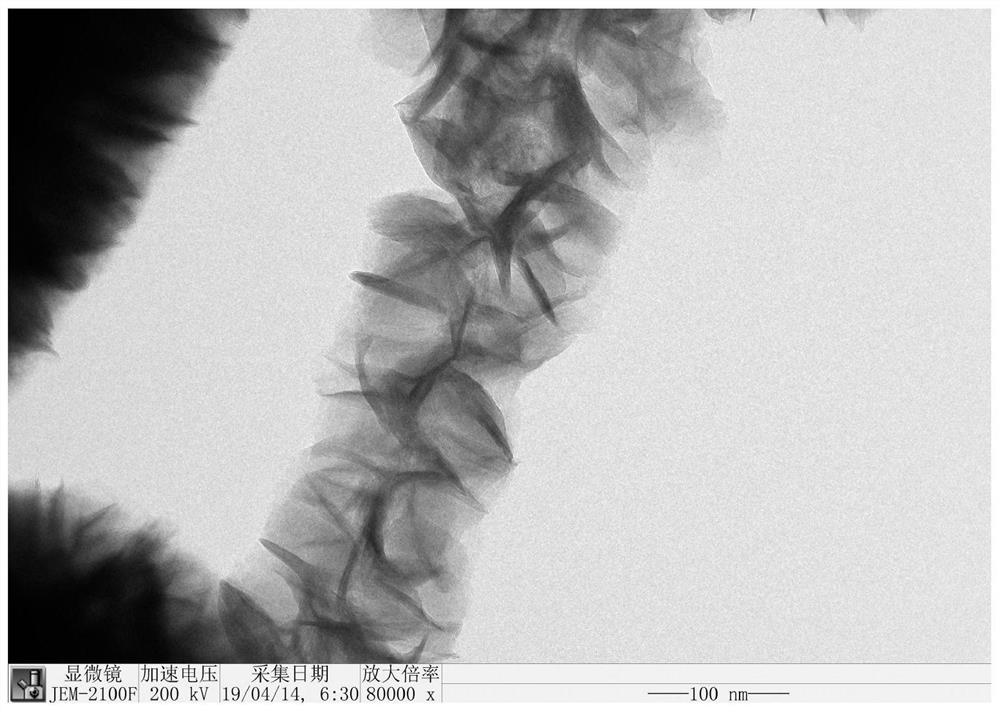

[0044] A metal phase molybdenum disulfide, the specific preparation method is as follows:

[0045] 1) Weigh 12 mg of molybdenum trioxide, 500 mg of sodium sulfide, 14 mg of thioacetamide and 0.12 g of urea, dissolve them in water, stir to form a uniform mixed solution, and obtain the first solution;

[0046] 2) Transfer the first solution to a 50mL reactor, seal the reactor, and place it in an oven for hydrothermal reaction at 200°C for 8 hours;

[0047] 3) Naturally cool to room temperature after the hydrothermal reaction, centrifuge the obtained solid product, wash it several times with deionized water and ethanol respectively, collect the solid product, and dry it in vacuum to obtain metal phase molybdenum disulfide powder.

Embodiment 2

[0049] A metal phase molybdenum disulfide, the specific preparation method is as follows:

[0050] 1) Weigh 14.4 mg of molybdenum trioxide, 39 mg of sodium sulfide and 0.12 g of urea, dissolve them in water, stir to form a uniform mixed solution, and obtain the first solution;

[0051] 2) Transfer the first solution to a 50mL reactor, seal the reactor, and place it in an oven for hydrothermal reaction at 160°C for 4 hours;

[0052] 3) Naturally cool to room temperature after the hydrothermal reaction, centrifuge the obtained solid product, wash it several times with deionized water and ethanol respectively, collect the solid product, and dry it in vacuum to obtain metal phase molybdenum disulfide powder.

Embodiment 3

[0054] A metal phase molybdenum disulfide, the specific preparation method is as follows:

[0055] 1) Weigh 14.4 mg of molybdenum trioxide, 312 mg of sodium sulfide and 0.12 g of urea, dissolve them in water, stir to form a uniform mixed solution, and obtain the first solution;

[0056] 2) Transfer the first solution to a 50mL reactor, seal the reactor, and place it in an oven for hydrothermal reaction at 240°C for 24 hours;

[0057] 3) Naturally cool to room temperature after the hydrothermal reaction, centrifuge the obtained solid product, wash it several times with deionized water and ethanol respectively, collect the solid product, and dry it in vacuum to obtain metal phase molybdenum disulfide powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com