Alkali-activated and nano-enhanced early strength type ultra-high performance concrete and preparation method thereof

A nano-enhanced, ultra-high performance technology used in building materials to achieve significant slip hardening properties, high shear bond strength, and reduced hydration reaction barriers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

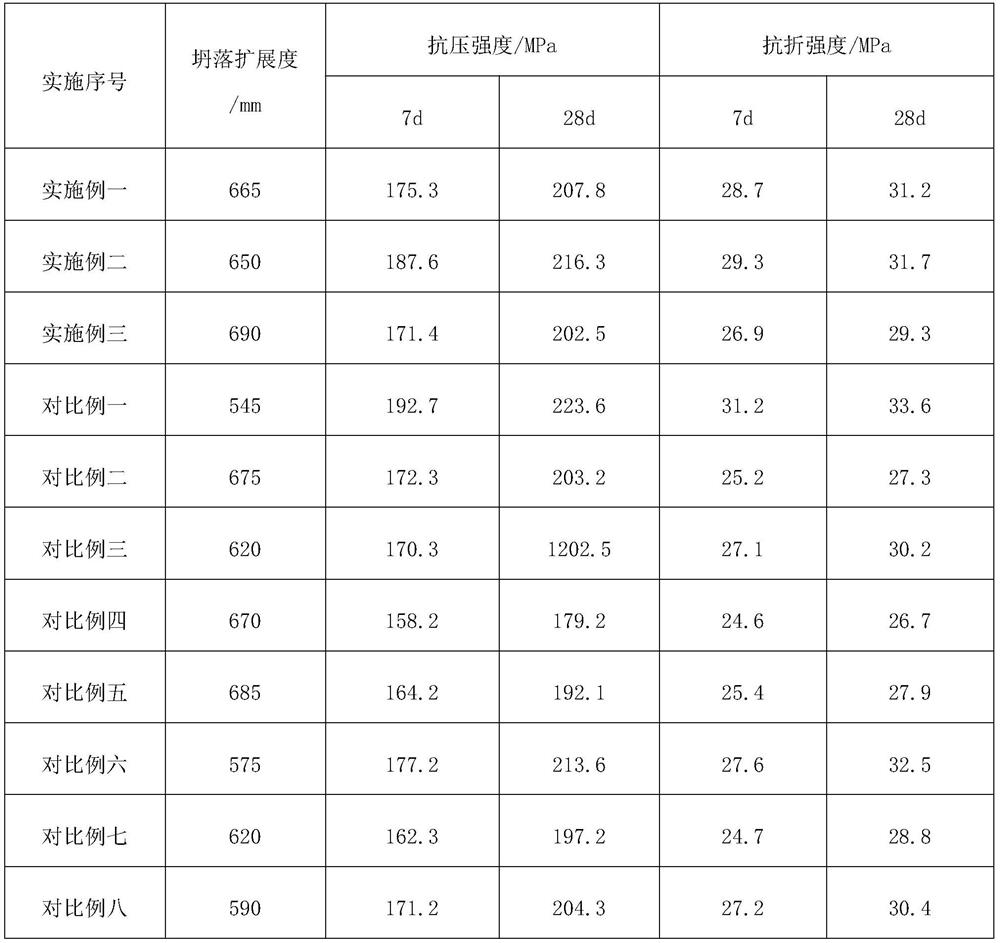

Examples

Embodiment 1

[0035] Alkali-activated, nano-reinforced early-strength ultra-high performance concrete is produced by the following method:

[0036] S1. Measure each raw material according to the production raw material formula;

[0037] 665kg of Portland cement, 124kg of silica fume, 184kg of mineral powder, 6kg of nano-silica, 1071kg of quartz sand with a particle size of less than 1mm (599.76kg of 20-40 mesh; 282.74kg of 40-70 mesh; 188.90kg of 70-140 mesh ) 128kg of copper-plated microfilament straight steel fiber, 32kg of twisted steel fiber, 14.685kg of water glass with a modulus of 1.3, 17.13kg of highly dispersed polycarboxylic acid solid water reducing agent with a water reducing rate of 40%, and 176.22kg of tap water;

[0038] The particle size of the nano silica is 19.6nm, the average particle size of silica fume is 0.08 μm, the particle size of mineral powder is 7.3 μm, and the average particle size of Portland cement is 17.7 μm;

[0039] The Portland cement is P.I 52.5R Portlan...

Embodiment 2

[0050] Alkali-activated, nano-reinforced early-strength ultra-high performance concrete is produced by the following method:

[0051] S1. Measure each raw material according to the production raw material formula;

[0052] 719.2kg of Portland cement, 111.4kg of silica fume, 182.3kg of mineral powder, 7kg of nano-silica, 1071kg of quartz sand with a particle size of less than 1mm (599.76kg of 20-40 mesh; 282.74kg of 40-70 mesh; 70-140 mesh Mesh 188.90kg) 112kg of copper-plated microfilament straight steel fiber, 28kg of twisted steel fiber, 15.20kg of water glass with a modulus of 1.2, 17.85kg of highly dispersed polycarboxylate solid water reducer with a water reducing rate of 40%, and 183.58 of tap water kg;

[0053] The particle size of the nano silica is 19.6nm, the average particle size of silica fume is 0.08 μm, the particle size of mineral powder is 7.3 μm, and the average particle size of Portland cement is 17.7 μm;

[0054] The Portland cement is P.I 52.5R Portland c...

Embodiment 3

[0065] Alkali-activated, nano-reinforced early-strength ultra-high performance concrete is produced by the following method:

[0066] S1. Measure each raw material according to the production raw material formula;

[0067] 660kg of Portland cement, 105kg of silica fume, 204kg of mineral powder, 5kg of nano-silica, 1074kg of quartz sand with a particle size of less than 1mm (of which 20-40 mesh 601.44kg; 40-70 mesh 283.53kg; 70-140 mesh 188.90kg ) 128kg of copper-plated microfilament straight steel fiber, 32kg of twisted steel fiber, 14.685kg of water glass with a modulus of 1.3, 17.13kg of highly dispersed polycarboxylic acid solid water reducer with a water reducing rate of 40%, and 180.19kg of tap water;

[0068] The particle size of the nano silica is 19.6nm, the average particle size of silica fume is 0.08 μm, the particle size of mineral powder is 7.3 μm, and the average particle size of Portland cement is 17.7 μm;

[0069] The Portland cement is P.I 52.5R Portland cemen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com