System for quickly converting biomass into gas-liquid-solid fertilizer

A gas-liquid-solid, biomass technology, applied in the field of biogas, can solve the problems of burning seedlings, low fertilizer maturity, heat loss and high input costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

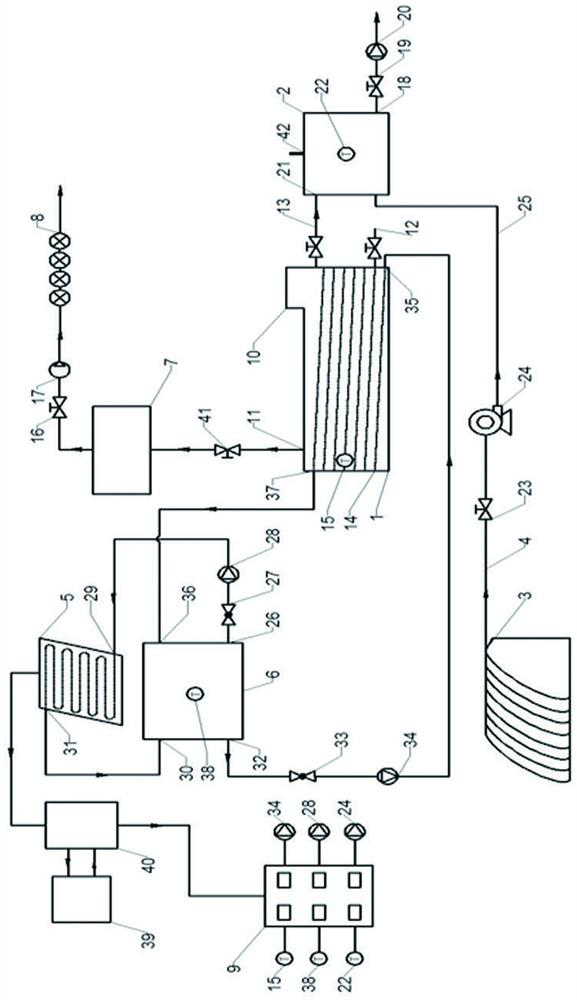

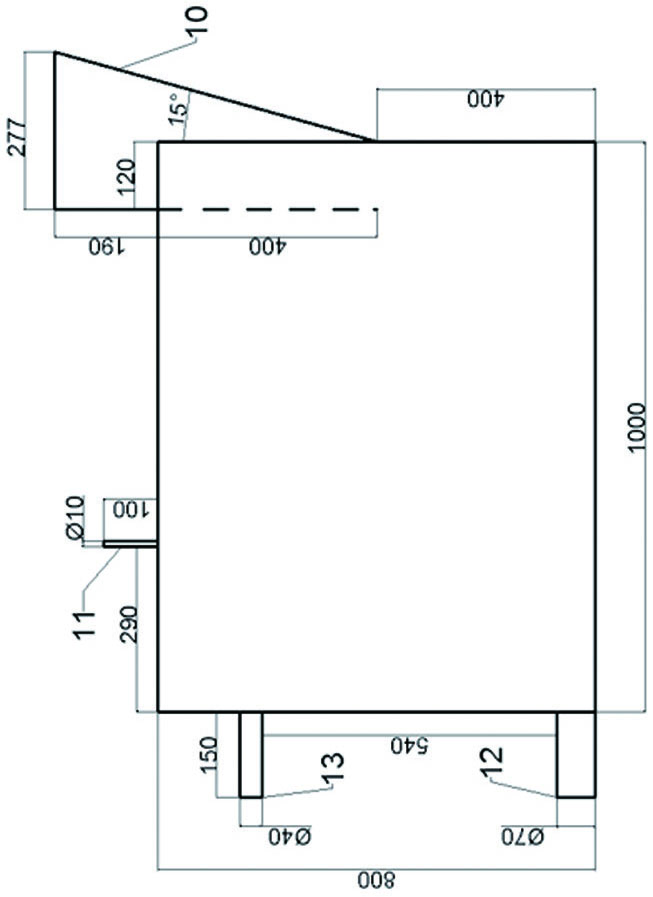

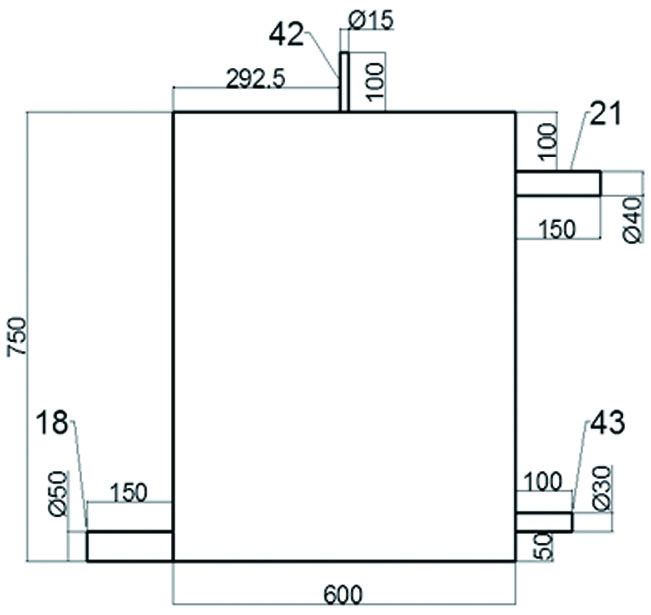

[0010] Such as figure 1 , figure 2 As shown, the present invention is a rapid conversion system from biomass to gas-liquid-solid fertilizer, including an anaerobic fermentation tank 1 for fermenting tail vegetable raw materials, a biogas slurry and biogas residue tank 2 for producing liquid organic fertilizer, for storing Greenhouse keel 3 for hot air, ventilation duct 4 for maturing biogas slurry and residue, PV / T board 5 for photothermal and photoelectric conversion, and heat storage tank 6 for storing hot water to heat the fermentation tank. Coil 14 for heating fermenter 1, gas bag 7 for collecting biogas, biogas lamp 8 for lighting biogas, control box 9 for controlling the start and stop of water pump and fan, and controlling and protecting PV / T The control inverter integrated machine 40 of the board line 5, and the battery pack 39 for storing electric energy, the anaerobic fermentation tank 1 includes an input port and an output port, and the input port of the anaerobic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com