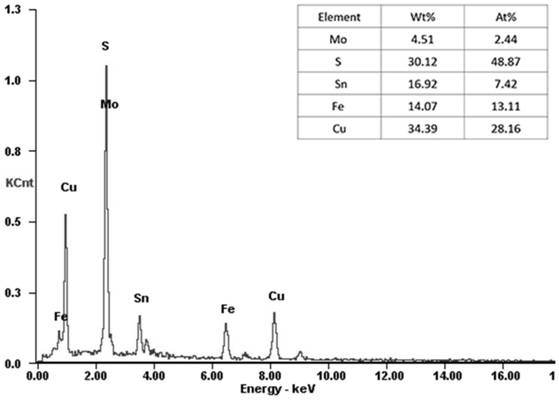

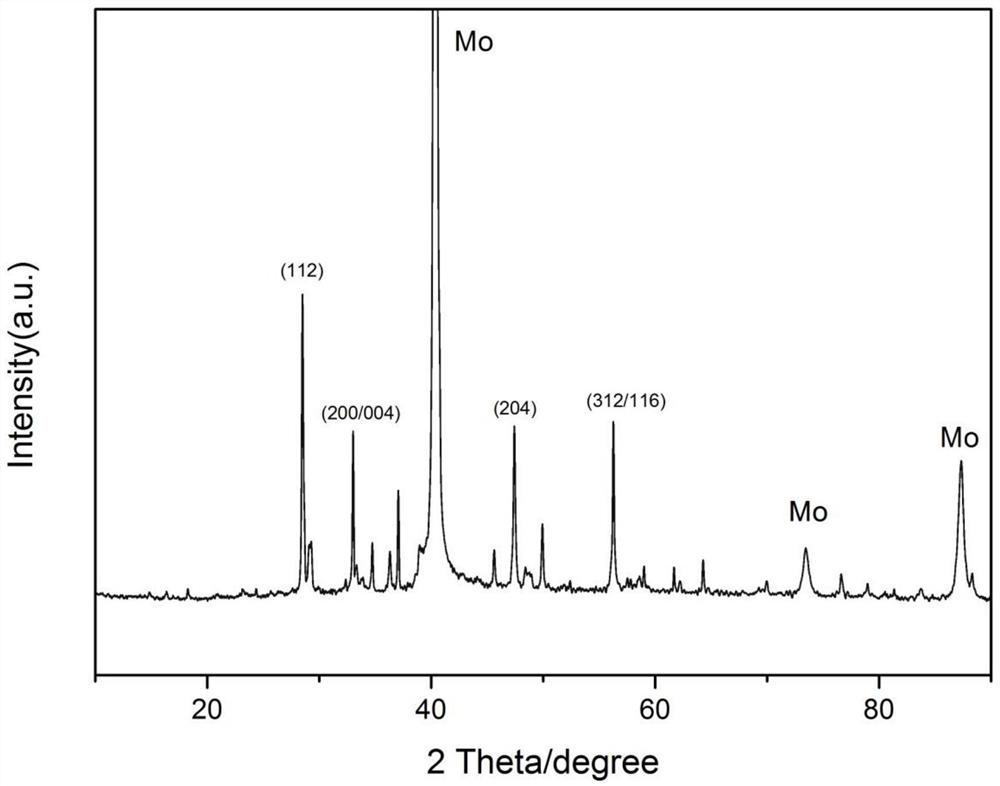

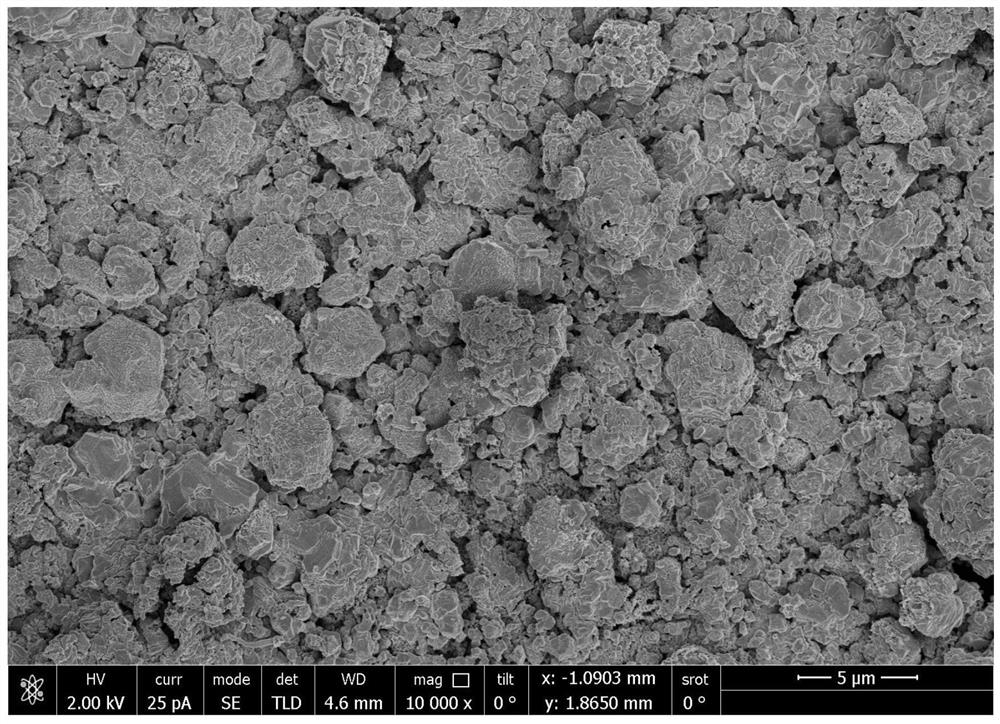

Low-cost copper-iron-tin-sulfur film with stannite structure and electrochemical preparation method of copper-iron-tin-sulfur film

A kesterite structure, copper-iron-tin-sulfur technology, applied in the low-cost kesterite structure Cu2FeSnS4 thin film and its electrochemical preparation, CFTS thin film solar cell absorber field, can solve the problem of high equipment price, complexity, and difficulty in large-scale production. Realization and other problems, to achieve the effect of easy deposition production, simple equipment and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 1) Clean the Mo glass substrate, (i) first wash the bottom with detergent to remove the grease on the hands and the substrate; (ii) then put the substrate in acetone solution for 10 minutes to remove the MoO on the Mo surface 3 (iii) then ultrasonically cleaning the substrate in an ethanol solution to remove residues of grease, acetone, etc. on the substrate; (iv) ultrasonically cleaning the substrate in ultrapure water for 10 minutes to clean the residual ethanol; (v ) to dry the substrate for use.

[0027] 2) Weigh 2mmol CuCl 2 2H 2 O, trisodium citrate of 10mmol, 5mmol tartaric acid are made the copper metal salt solution of PH=4.6. Cu / Mo precursor thin films were prepared by using Mo-coated glass as the working electrode, graphite as the counter electrode, and a saturated calomel electrode as the reference electrode. The working electrode was deposited in a copper electrolyte at a constant potential of -1.1V for 1600s.

[0028] 3) Weigh 3mmol SnCl 4 2H 2 O, 3mm...

Embodiment 2

[0033] 1) Clean the Mo glass substrate, (i) first wash the bottom with detergent to remove the grease on the hands and the substrate; (ii) then put the substrate in acetone solution for 10 minutes to remove the MoO on the Mo surface 3 (iii) then ultrasonically cleaning the substrate in an ethanol solution to remove residues of grease, acetone, etc. on the substrate; (iv) ultrasonically cleaning the substrate in ultrapure water for 10 minutes to clean the residual ethanol; (v ) to dry the substrate for use.

[0034] 2) Weigh 2mmol CuCl 2 2H 2 O, trisodium citrate of 10mmol, 5mmol tartaric acid are made the copper metal salt solution of PH=4.6. Cu / Mo precursor thin films were prepared by using Mo-coated glass as the working electrode, graphite as the counter electrode, and a saturated calomel electrode as the reference electrode. The working electrode was deposited in a copper electrolyte at a constant potential of -0.8V for 1600s.

[0035] 3) Weigh 3mmol SnCl 4 2H 2O, 3mmo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com