Quick-attenuation high-light-output gallium oxide scintillation crystal and preparation method thereof

A technology of scintillation crystals and gallium oxide, which is applied in chemical instruments and methods, crystal growth, scintillation components, etc., can solve the problem of unsatisfactory comprehensive scintillation performance of doped gallium oxide crystals, uneven distribution of doped ions, and reduction of total light output, etc. problems, to achieve the effects of comprehensive flicker performance improvement, increased forced convection, and improved consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

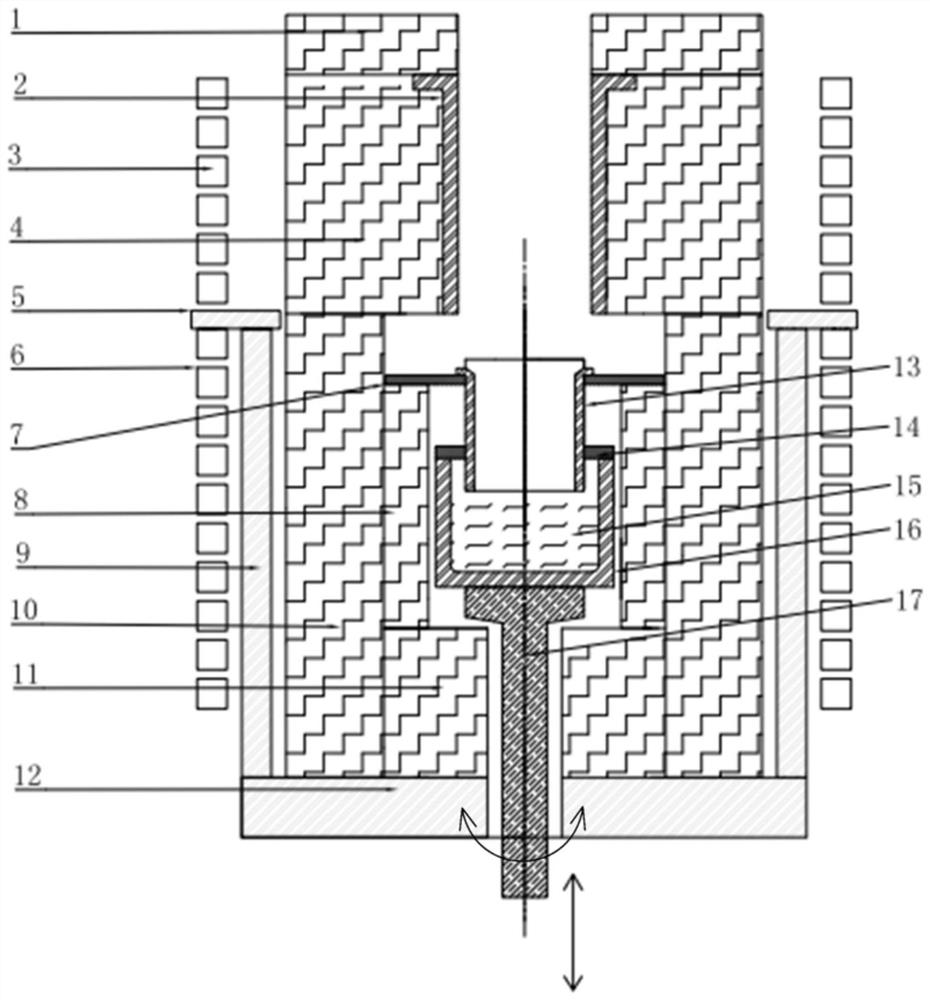

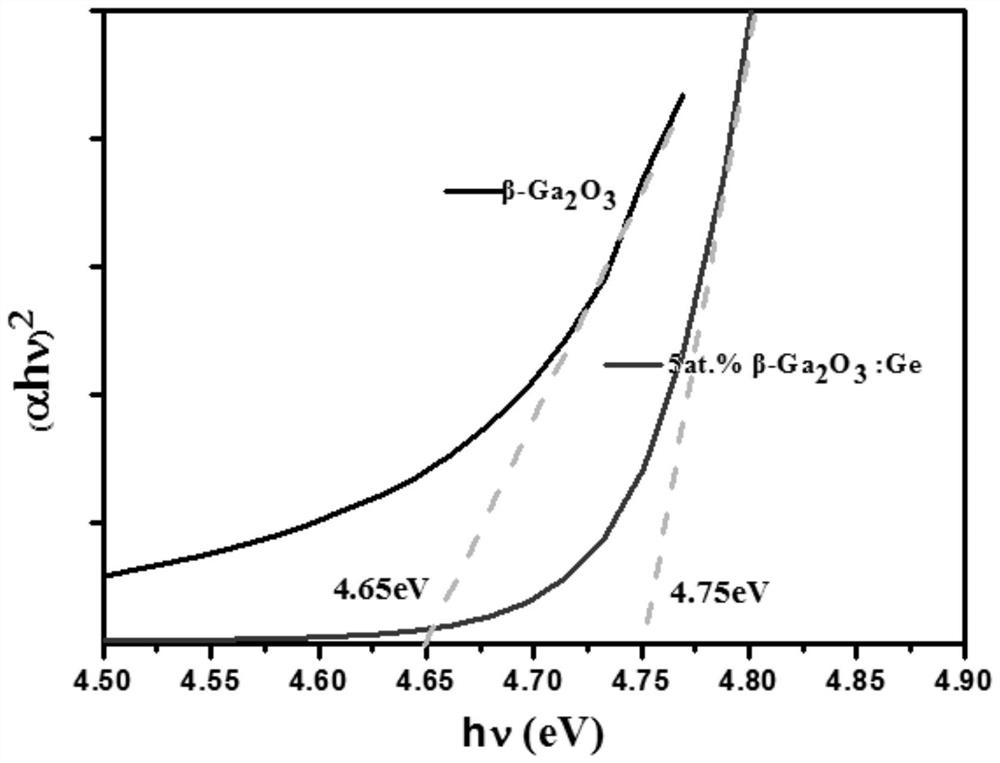

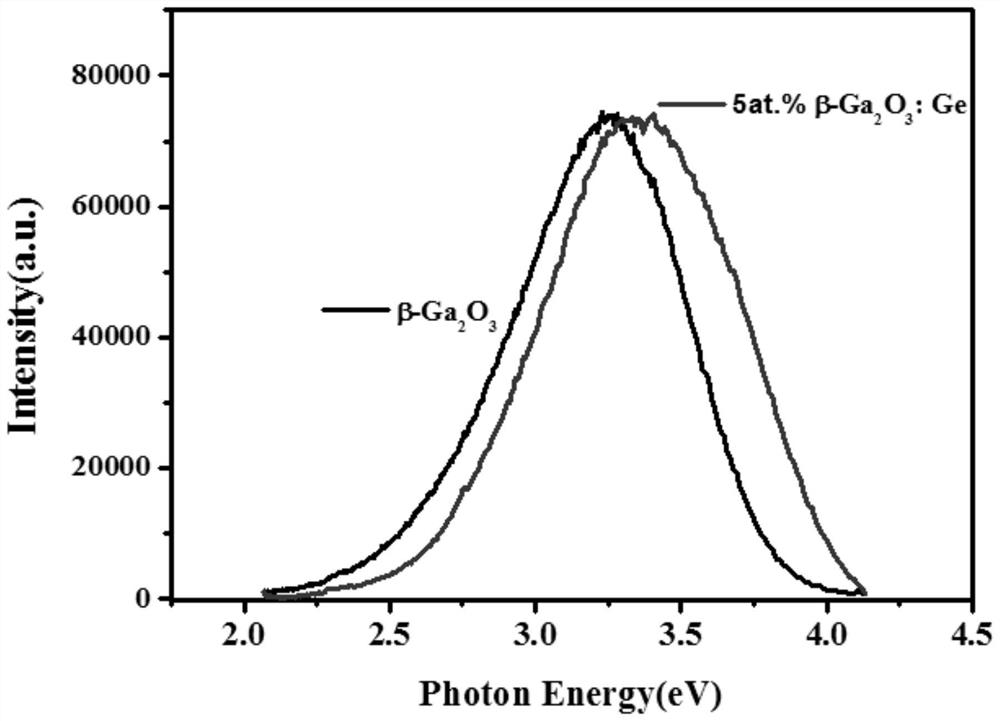

[0043] In this embodiment, the medium frequency induction dual temperature zone heating method is adopted, and the specific device can be found in figure 1 shown. High-purity gallium oxide (99.9999%) and doping amount 5at.% high-purity GeO 2 (99.9999%) raw material powders are fully mixed, isostatically pressed, and sintered at a constant temperature of 1500° C. for 15 hours to obtain gallium oxide ceramic raw materials for crystal growth. Put the gallium oxide ceramic raw material into the iridium crucible of the guided mold furnace, put the plate-shaped β-Ga 2 o 3 The seed crystal is placed in the seed crystal holder. The guided mold furnace is evacuated to 5Pa and then filled with 99.999% pure He gas + CO 2 gas mixture (CO 2 :He=1:3) until the pressure in the furnace is 1.02MPa, medium frequency induction heating dual temperature zone heating, the heating power of the main temperature zone is 11.5KW, and the heating power of the auxiliary temperature zone is lower than...

Embodiment 2

[0054] High-purity gallium oxide (99.9999%) and doping amount 2at.% high-purity GeO 2 (99.9999%) and doping amount 3at.% high-purity Al 2 o 3 (99.9999%) raw material powders are fully mixed, isostatically pressed, and sintered at a constant temperature of 1600° C. for 20 hours to obtain gallium oxide ceramic raw materials for crystal growth. Put the gallium oxide ceramic raw material into the iridium crucible of the guided mold furnace, and put the plate-shaped β-Ga 2 o 3 The seed crystal is placed in the seed crystal holder. The guided mold furnace is evacuated to 5Pa and then filled with 99.999% pure He gas + CO 2 gas mixture (CO 2 :He=1:1) until the pressure in the furnace is 1.1MPa, medium frequency induction heating dual temperature zone heating, the heating power of the main temperature zone is 11.7KW, and the heating power of the auxiliary temperature zone is lower than the heating power of the main temperature zone 2KW. After heating in dual temperature zones unt...

Embodiment 3

[0057] High-purity gallium oxide (99.9999%) and doping amount 10at.% high-purity Al 2 o 3 (99.9999%) raw material powders are fully mixed, isostatically pressed, and sintered at a constant temperature of 1600° C. for 14 hours to obtain gallium oxide ceramic raw materials for crystal growth. Put the gallium oxide ceramic raw material into the iridium crucible of the guided mold furnace, and put the plate-shaped β-Ga 2 o 3 The seed crystal is placed in the seed crystal holder. The guided mold furnace is evacuated to 5Pa and then filled with 99.999% pure He gas + CO 2 gas mixture (CO 2:He=1:2) until the furnace pressure is 1.05MPa, medium frequency induction heating double temperature zone heating, the heating power of the secondary temperature zone is lower than the heating power of the main temperature zone 2KW. After heating in dual temperature zones until the raw materials in the crucible are completely melted, the crucible rises slowly at a rate of 5mm / min, so that the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com