Efficient water-saving cloth dyeing and finishing process

A water-saving, fabric technology, applied in the field of textile printing and dyeing, can solve the problems of increasing the difficulty and cost of washing water recycling, secondary adhesion to the surface of the fabric, and increased cleaning water consumption, so as to reduce the amount of cleaning water, Reduce process water consumption and reduce the effect of cleaning water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Embodiment 1: a kind of efficient water-saving type cloth dyeing and finishing process comprises the following steps:

[0045] S1. Singeing and trimming of the gray cloth: send the gray cloth to the singeing machine for singeing treatment, and remove the hair balls and burrs of the gray cloth;

[0046] S2, desizing and bleaching: putting the fabric singed in step S1 into the desizing and bleaching solution for desizing and bleaching;

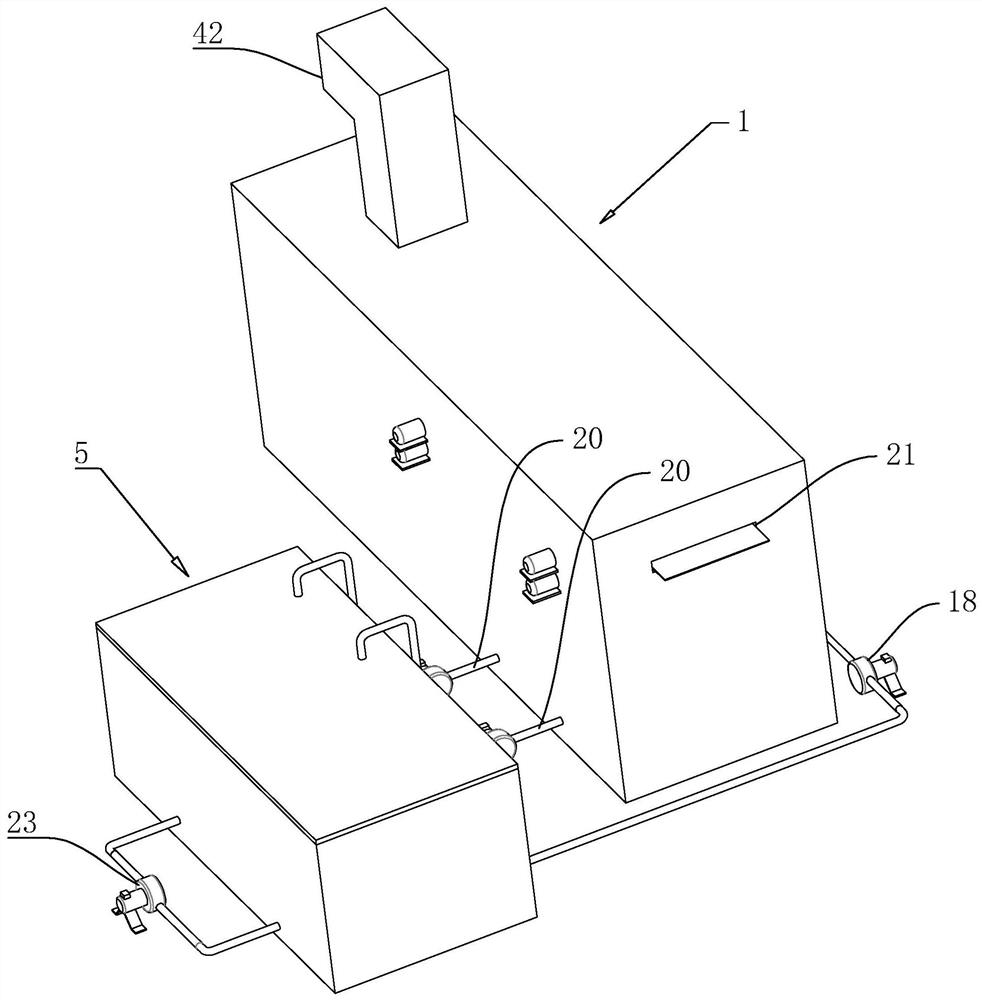

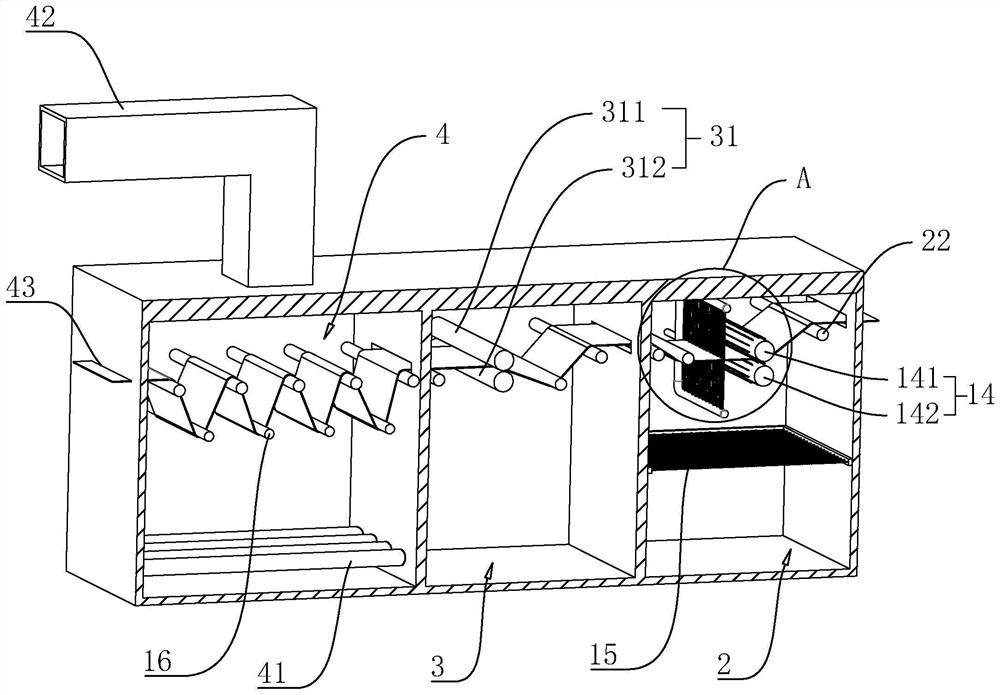

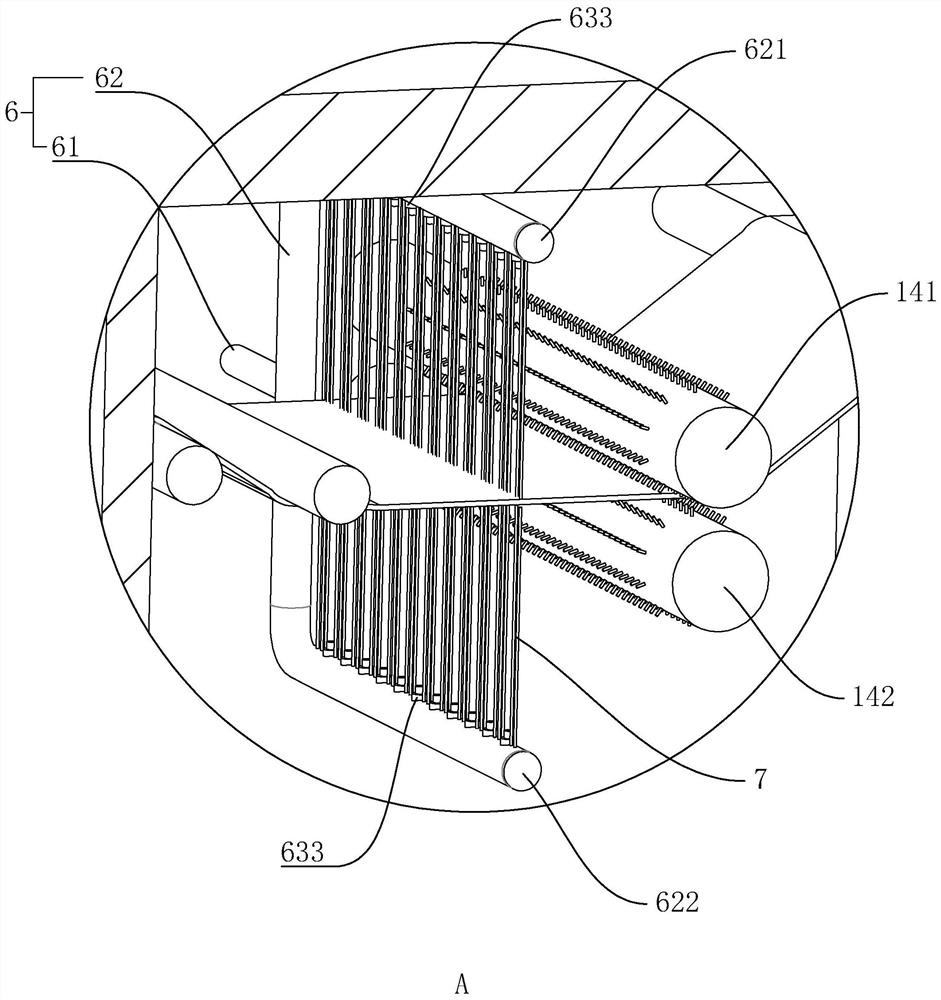

[0047] S3. Cleaning and drying: send the cloth bleached in step S2 to the integrated cleaning and drying equipment 1 for cleaning and drying;

[0048] S4. Cloth dyeing: adding the dried cloth in step S3 into the dye solution for exhaust dyeing.

[0049] Among them, the desizing bleaching solution contains the following components by weight: 4 parts of biological enzymes, 3 parts of hydrogen peroxide, 3 parts of sodium hydroxide, 1 part of tetraacetylethylenediamine, 2 parts of penetrating agent, 2 parts of sodium silicate, 5 parts of whi...

Embodiment 2

[0050] Embodiment 2: a kind of efficient water-saving type cloth dyeing and finishing process, comprises the following steps:

[0051] S1. Singeing and trimming of the gray cloth: send the gray cloth to the singeing machine for singeing treatment, and remove the hair balls and burrs of the gray cloth;

[0052] S2, desizing and bleaching: putting the fabric singed in step S1 into the desizing and bleaching solution for desizing and bleaching;

[0053] S3. Cleaning and drying: send the cloth bleached in step S2 to the integrated cleaning and drying equipment 1 for cleaning and drying;

[0054] S4. Cloth dyeing: adding the dried cloth in step S3 into the dye solution for exhaust dyeing.

[0055] Among them, the desizing bleaching solution contains the following components by weight: 8 parts of biological enzymes, 6 parts of hydrogen peroxide, 4 parts of sodium hydroxide, 1.5 parts of tetraacetylethylenediamine, 3 parts of penetrating agent, 3 parts of sodium silicate, 8 parts of...

Embodiment 3

[0056] Embodiment 3: a kind of efficient water-saving type cloth dyeing and finishing process comprises the following steps:

[0057] S1. Singeing and trimming of the gray cloth: send the gray cloth to the singeing machine for singeing treatment, and remove the hair balls and burrs of the gray cloth;

[0058] S2, desizing and bleaching: putting the fabric singed in step S1 into the desizing and bleaching solution for desizing and bleaching;

[0059] S3. Cleaning and drying: send the cloth bleached in step S2 to the integrated cleaning and drying equipment 1 for cleaning and drying;

[0060] S4. Cloth dyeing: adding the dried cloth in step S3 into the dye solution for exhaust dyeing.

[0061] Among them, the desizing bleaching solution contains the following components by weight: 12 parts of biological enzymes, 9 parts of hydrogen peroxide, 5 parts of sodium hydroxide, 2.5 parts of tetraacetylethylenediamine, 4 parts of penetrating agent, 4 parts of sodium silicate, 10 parts o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com