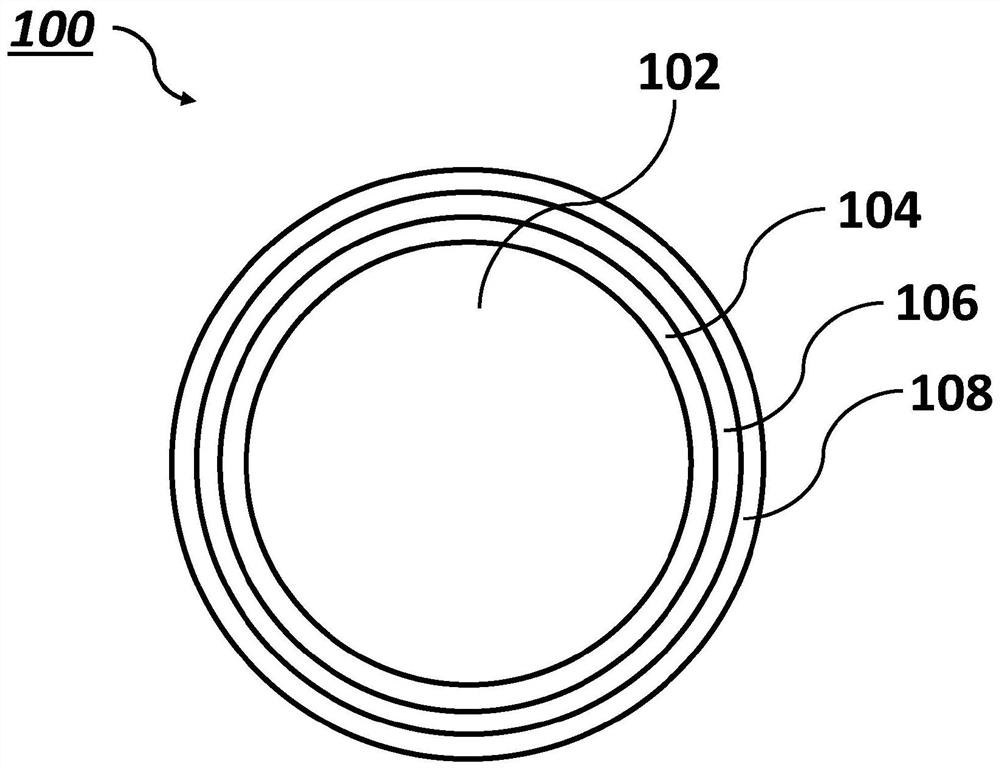

Smart release nitrogen-containing fertilizer granules

A technology of fertilizer granules and nitrogen fertilizers, applied in nitrogen fertilizers, inorganic fertilizers, organic fertilizers, etc., can solve problems such as unsuitability for use and urea granules sticking together.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

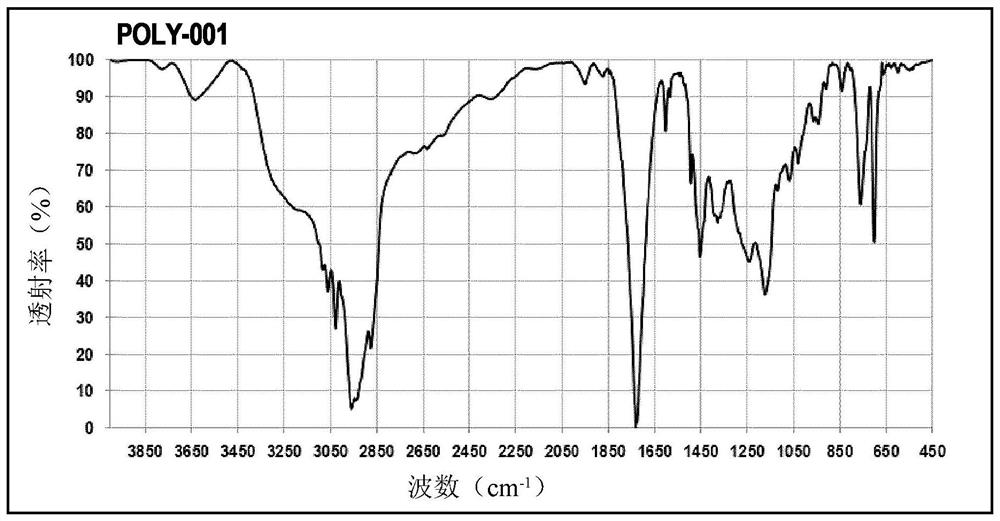

[0471] Example 1 - Water-swellable copolymer nanoparticles POLY-001

[0472] Synthesis of copolymer nanoparticles POLY-001 (as an aqueous suspension) was accomplished by mixing a prepolymer solution comprising 236 Kg of deionized water, 39.6 Kg styrene, 39.6Kg n-butyl acrylate, 0.82Kg acrylic acid, 2.48Kg triethoxyvinylsilane, 0.82Kg ammonium bicarbonate and 0.82Kg n-octanol. In a separate small tank, a solution of ammonium persulfate free radical initiator was prepared by dissolving 0.42 Kg of ammonium persulfate in 10 Kg of deionized water.

[0473] One hundred and sixty kilograms of prepolymer solution was charged to the reactor. The temperature was slowly raised to 80°C and the remaining prepolymer solution was added to the reactor at a rate of 32.0 Kg per hour using a metering pump. At the same time, ammonium persulfate solution was also fed into the reactor using a metering pump at a rate of 2.00 Kg per hour.

[0474] After the two solutions were completely added to t...

example 2

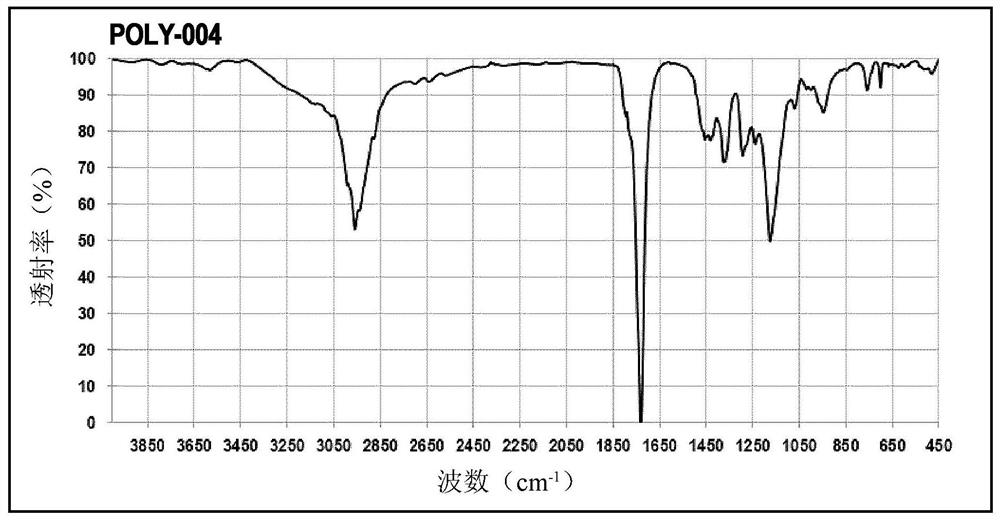

[0480] Example 2 - Water insoluble copolymer nanoparticles POLY-004

[0481] Synthesis of copolymer nanoparticles POLY-004 (as an aqueous suspension) was accomplished by mixing a prepolymer solution comprising 236 Kg of deionized water, 50.0 Kg styrene, 50.0Kg butyl methacrylate, 0.82Kg ammonium bicarbonate and 0.82Kg n-octanol. In a separate small tank, a solution of ammonium persulfate free radical initiator was prepared by dissolving 0.42 Kg of ammonium persulfate in 10 Kg of deionized water.

[0482] One hundred and sixty kilograms of prepolymer solution was charged to the reactor. The temperature was slowly raised to 80°C and the remaining prepolymer solution was added to the reactor at a rate of 32.0 Kg per hour using a metering pump. At the same time, ammonium persulfate solution was also fed into the reactor using a metering pump at a rate of 2.00 Kg per hour.

[0483] After the two solutions were completely added to the reactor, the polymerization was continued at ...

example 3

[0489] Example 3 - Water insoluble copolymer nanoparticles POLY-005

[0490] Synthesis of copolymer nanoparticles POLY-005 (as an aqueous suspension) was accomplished by mixing a prepolymer solution comprising 236 Kg of deionized water, 47.0 Kg styrene, 50.0Kg butyl methacrylate, 3.00Kg N,N-dimethylaminoethyl methacrylate, 0.82Kg ammonium bicarbonate and 0.82Kg n-octanol. In a separate small tank, a solution of ammonium persulfate free radical initiator was prepared by dissolving 0.42 Kg of ammonium persulfate in 10 Kg of deionized water.

[0491] One hundred and sixty kilograms of prepolymer solution was charged to the reactor. The temperature was slowly raised to 80°C and the remaining prepolymer solution was added to the reactor at a rate of 32.0 Kg per hour using a metering pump. At the same time, ammonium persulfate solution was also fed into the reactor using a metering pump at a rate of 2.00 Kg per hour.

[0492] After the two solutions were completely added to the r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com