Triethylamine wastewater pretreatment system

A pretreatment, triethylamine technology, applied in water/sewage treatment, heating water/sewage treatment, neutralized water/sewage treatment, etc., can solve the problems of high operating cost, easy scaling of pipelines, high labor intensity, etc. Achieve the effect of high degree of equipment integration, no secondary pollution and low operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in detail below in conjunction with specific embodiments.

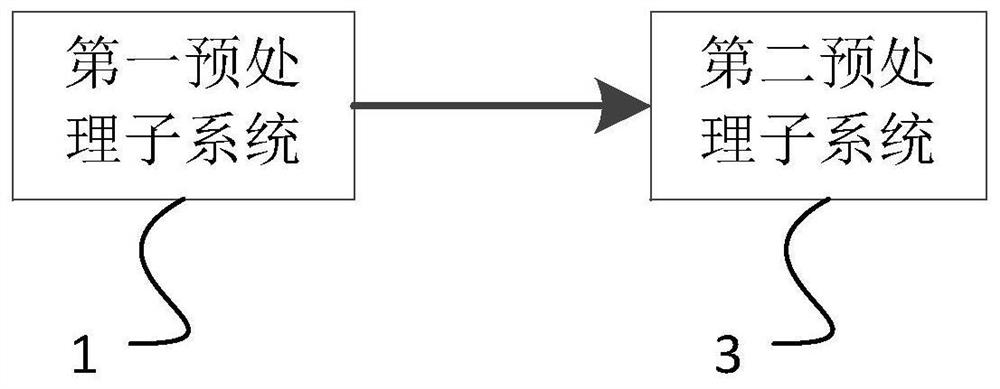

[0037] Such as figure 1 Shown, a kind of triethylamine wastewater pretreatment system comprises,

[0038] The first pretreatment subsystem 1: used to remove calcium ions in triethylamine wastewater;

[0039] The second pretreatment subsystem 3: remove the salt content of the wastewater treated by the first pretreatment subsystem 1, and adjust the COD value to the set range;

[0040] The first pretreatment subsystem 1 is connected to the second pretreatment subsystem 3 through pipelines, and the first pretreatment subsystem 1 is provided with a triethylamine wastewater inlet.

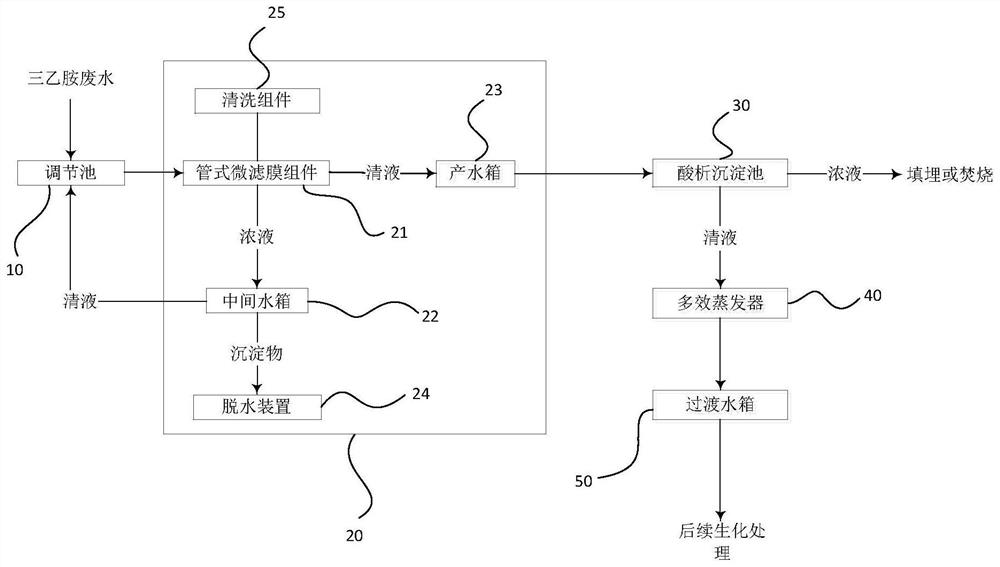

[0041] Such as figure 2 As shown, the first pretreatment subsystem 1 system includes a regulating tank 10 and a tubular microfiltration system 20 connected to each other. The regulating pond 10 is provided with a triethylamine waste water inlet, and the tubular microfiltration system 20 is conne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| chemical oxygen demand (mass) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com