Enameled wire paint remover and preparation method thereof

A paint stripper, enameled wire technology, applied in the direction of chemical paint/ink remover, coating, etc., can solve the problems of low paint stripping efficiency, high corrosion of the substrate, unclean stripping, etc. Good effect, avoid corrosion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

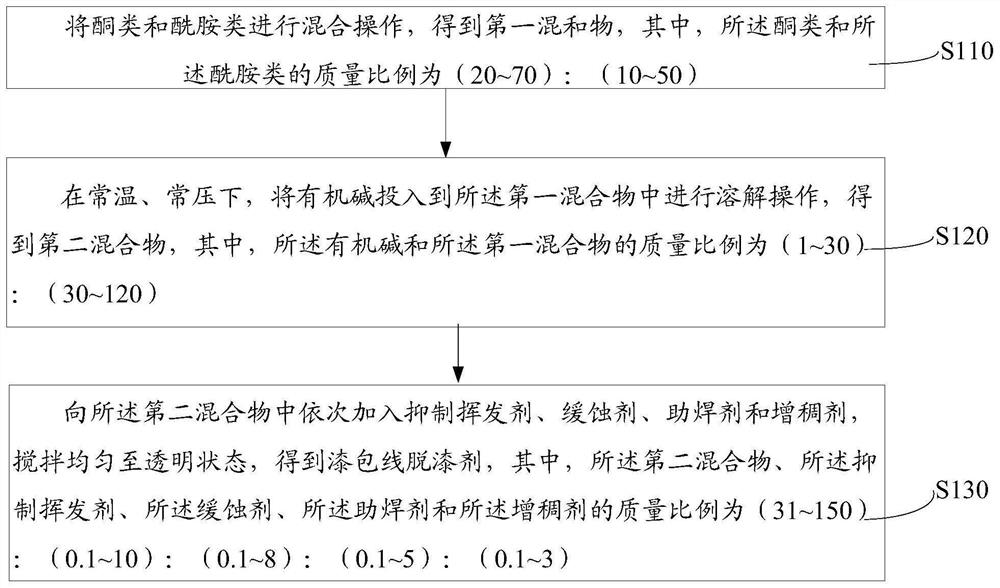

[0037] For an implementation, see figure 1 , a preparation method of enameled wire paint stripper, comprising the following steps:

[0038] S110. Mixing ketones and amides to obtain a first mixture, wherein the mass ratio of the ketones to the amides is (20-70):(10-50).

[0039] By mixing ketones and amides, of course, an appropriate amount of pure water can also be added, after fully dissolving and stirring uniformly, the first mixture can be obtained, which is convenient for subsequent preparation to obtain enameled wire paint remover, wherein the ketones and the The mass ratio of amides is (20-70): (10-50). It can be understood that if the same material is used in different proportions, the performance of the obtained mixture may be very different. In this embodiment, by controlling the The specific ratio of the ketones and the amides can make the ketones and the amides play a better synergistic effect, which is beneficial to the preparation of an enameled wire paint remov...

Embodiment 1

[0049] 450g of methyl isobutyl ketone, 200g of 1,1,3-trimethylcyclohexenone, 100g of formamide, and 206g of N,N-dimethylacetamide were mixed to obtain the first mixture;

[0050] At normal temperature and normal pressure, 20g of triethylenetetramine and 10g of triethanolamine were put into the first mixture for dissolving operation to obtain the second mixture;

[0051] In the second mixture, add 10g polyethylene glycol, 1.5g MBT-Na, 1g succinic acid, 1.5g hydroxyethyl cellulose successively, stir until transparent state, obtain the enameled wire paint remover of embodiment 1;

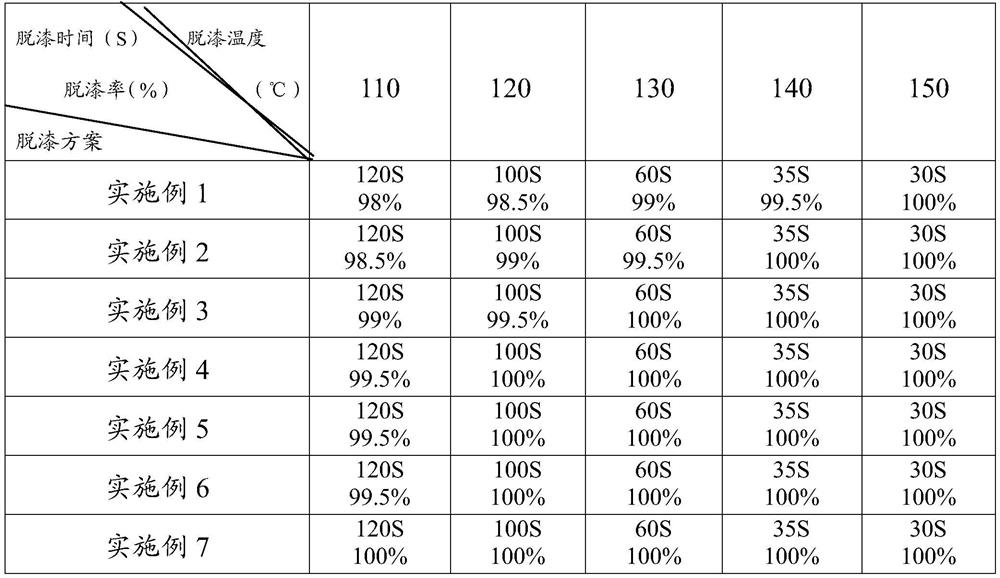

[0052] Under the temperature condition of 110° C. to 150° C., the enameled wire is soaked in the enameled wire paint remover of Example 1, and the paint stripping operation is performed for 30S to 120S, so that the paint film on the enameled wire is dissolved and peeled off.

Embodiment 2

[0054] 450g of N-vinylpyrrolidone, 200g of propiophenone, 170g of N,N-dimethylformamide, and 136g of N,N-dimethylacetamide were mixed to obtain the first mixture;

[0055] At normal temperature and normal pressure, 20g of tetraethylenepentamine and 10g of triethanolamine were put into the first mixture for dissolving operation to obtain the second mixture;

[0056] In the second mixture, add 10g polyethylene glycol, 1.5g REOMENT-3, 1g inactive rosin flux, 1.5g polyvinyl alcohol successively, stir until transparent state, obtain the enameled wire paint remover of embodiment 2;

[0057] Under the temperature condition of 110° C. to 150° C., the enameled wire is soaked in the enameled wire paint remover of Example 2, and the paint stripping operation is performed for 30 s to 120 s, so that the paint film on the enameled wire is dissolved and peeled off.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com