Marine diesel engine compressed air supply soot blower and tail gas treatment system

A marine diesel engine and compressed air technology, applied in exhaust gas treatment, gas treatment, exhaust devices, etc., can solve the problems of low soot blowing intensity of sonic soot blower, accelerated catalyst deactivation, and soot deposition and adhesion, etc., to achieve Good atomization effect, prolong service life and save operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

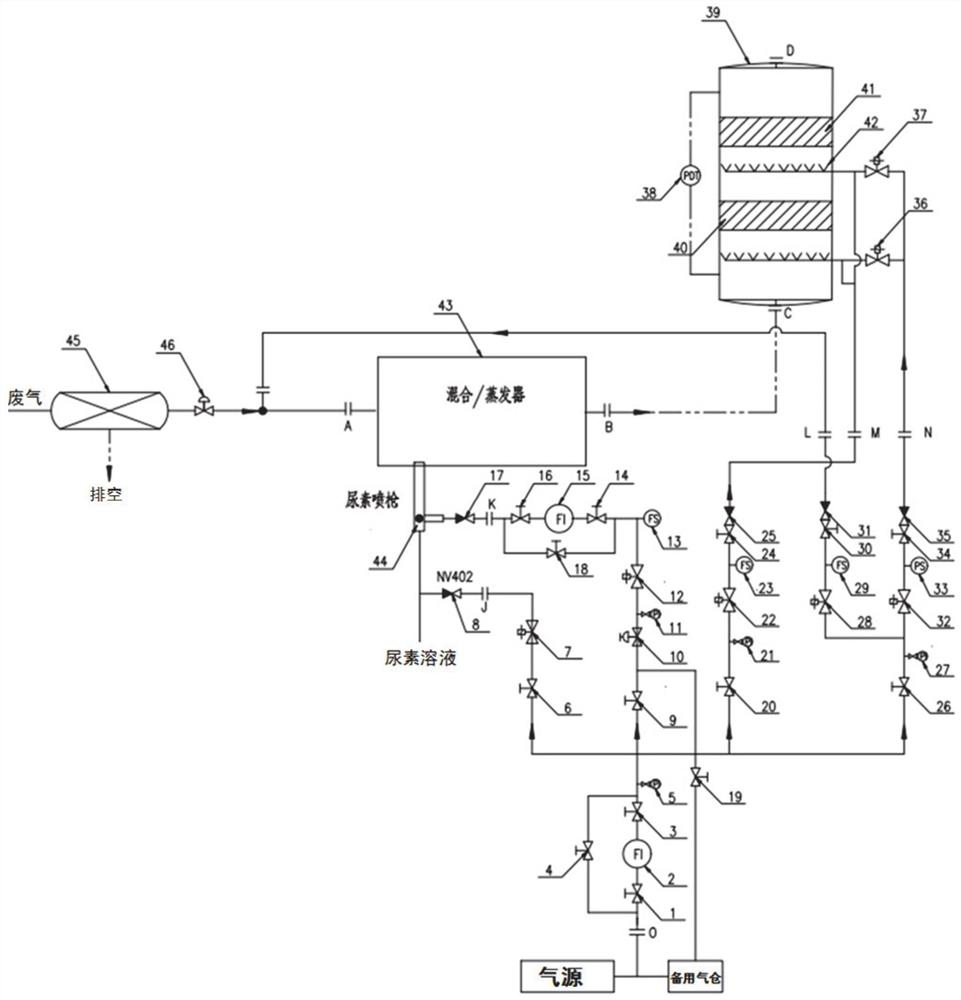

[0030] In a typical implementation of the present disclosure, such as figure 1 As shown, a marine diesel engine compressed air supply soot blowing device is proposed.

[0031] It includes an air supply mechanism, an atomization mechanism and a dust removal mechanism. The atomization mechanism includes a urea purge module and an atomization module that are respectively connected to the gas supply mechanism through pipelines. The dust removal mechanism includes a sealing module that is respectively connected to the gas supply mechanism through pipelines. And the soot blowing pipe arranged in the reactor, the sealing module is used to output the air flow to block the counterflow of exhaust gas in the reactor, the soot blowing nozzle is arranged on the soot blowing pipe group, and it is arranged upstream of the corresponding catalyst; the ventilation mechanism includes a pipeline connected Ventilation modules of the air supply mechanism;

[0032] In this embodiment, the air suppl...

Embodiment 2

[0055] In another typical implementation of the present disclosure, such as figure 1 As shown, a ship exhaust gas treatment system is proposed.

[0056] The soot blowing device was supplied with compressed air from a marine diesel engine as described in Example 1.

[0057] The reactor is connected to the diesel engine exhaust pipe through the pipeline, the output end of the urea spray gun is connected to the mixer, the atomization module of the atomization mechanism is connected to the urea spray gun, the soot blowing pipe is arranged in the reactor, and the sealing module cooperates with the reactor to seal piping;

[0058] The reactor is equipped with a differential pressure sensor, and the test ends of the differential pressure sensor are respectively arranged at the inlet and outlet of the reactor;

[0059] There are multiple layers of catalysts arranged in the reactor along the flow direction of the flue gas, and the upstream of each layer of catalysts is equipped with ...

Embodiment 3

[0063] In yet another typical embodiment of the present disclosure, a working method of the ship exhaust gas treatment system as described in Embodiment 2 is provided.

[0064] combine figure 1 , to describe the working process of the exhaust gas treatment system in detail:

[0065] In the initial state, all valves are closed.

[0066] In the preparation stage, open the first ball valve 1, the second ball valve 3, the fourth ball valve 6, the fourth ball valve 8, the fifth ball valve 9, the sixth ball valve 14, the seventh ball valve 16, the tenth ball valve 20, and the eleventh ball valve 24 , the twelfth ball valve 26, the thirteenth ball valve 30, and the fourteenth ball valve 34.

[0067] When the main engine is running in the non-ECA area, there is no need to run the SCR system, the bypass valve 46 is closed, the exhaust gas is discharged from the exhaust pipe, and does not enter the reactor to participate in the reaction. The fourth solenoid valve 28 is energized to wo...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap