Cutting state edge intelligent monitoring method based on online incremental wear evolution model

A technology of intelligent monitoring and intelligent monitoring system, applied in the direction of neural learning method, biological neural network model, measuring/indicating equipment, etc., can solve the problems of insufficient accuracy, inability to judge the real-time wear of tools, and consumption of large time and space resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0121] In order to make the technical problems, technical solutions and beneficial effects to be solved by the technology clearer and clearer, the technology will be further described in detail below in conjunction with the accompanying drawings.

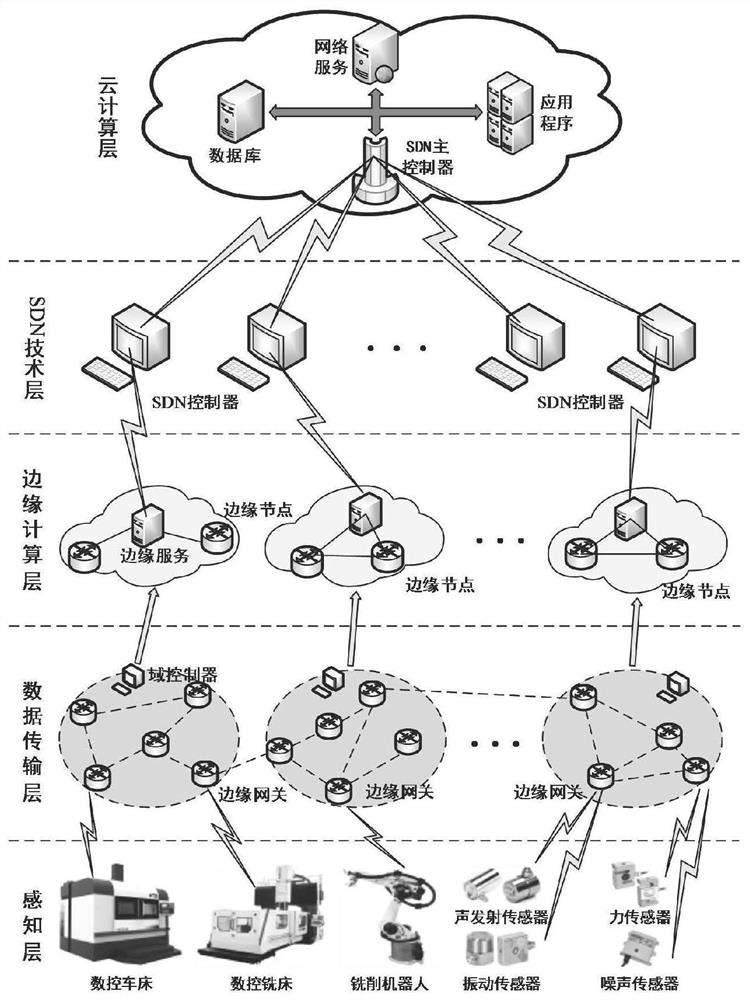

[0122] Such as figure 1 As shown, the cutting state edge intelligent monitoring method based on the online incremental wear evolution model involved in the method described in this technology includes the following steps:

[0123] S1: Construct a tool edge intelligent monitoring system, such as figure 1 shown;

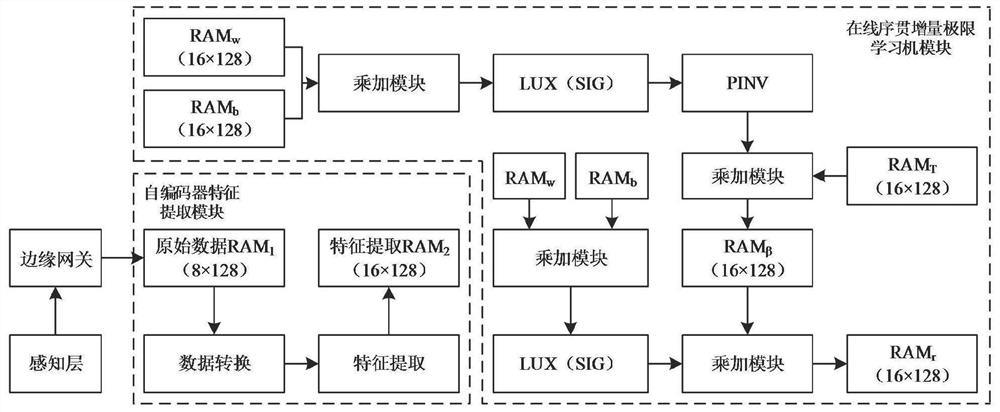

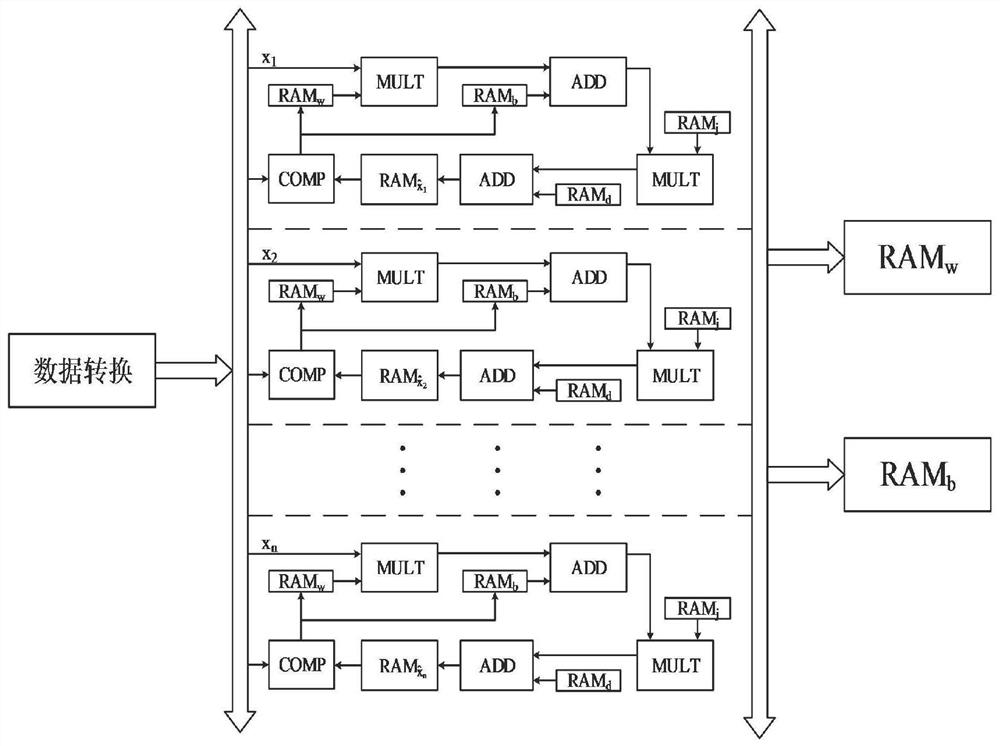

[0124] Specifically, in S1, a tool edge intelligent monitoring system is constructed, which is divided into five layers of logical entities: perception layer, data transmission layer, edge computing layer, SDN technology layer and cloud computing layer. The perception layer is composed of cutting force, vibration, acoustic emission, noise and other sensors. The three-way cutting force sensor is used to collect the cutting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com