Environmentally friendly bio-based high light-shielding flame-retardant composite material and preparation method thereof

A kind of flame-retardant composite material and environment-friendly technology, applied in the field of flame-retardant materials, can solve the problems of high shading, unrealizable, bad experience, etc., and achieve high shading, good application performance, high-efficiency charcoal flame-retardant Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

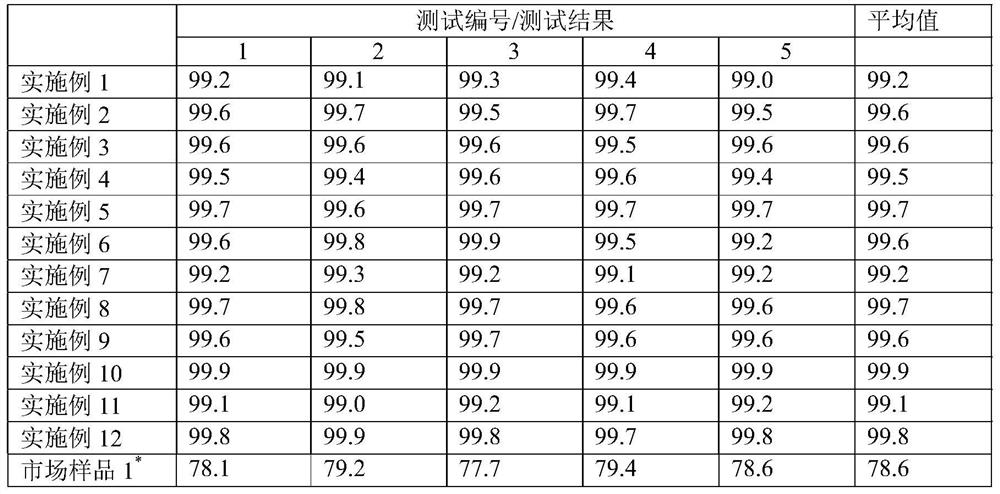

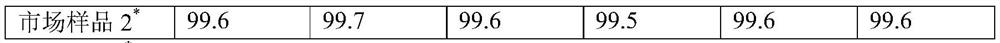

Examples

Embodiment 1

[0046] Calculated in parts by mass, weigh 6 kg of domestic pigment carbon black BKL C311, 0.4 kg of ultraviolet absorber UV-326 (2'-(2'-hydroxy-3'-tert-butyl-5'-methylphenyl)- 5-Chlorobenzotriazole), 2.5 kg of 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide (DOPO), 10 kg of silane-modified Type II ammonium polyphosphate, 4 kg Melamine isocyanurate, 0.6 kg maleic anhydride grafted polyethylene, 0.25 kg n-octadecyl β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate, 0.25 kg trioctyl base phosphite, 60 kg of polyethylene, 18 kg of hydroxypropyl starch ether (HPS). After the materials are uniformly mixed in the mixer, they are added to the twin-screw extruder and extruded. The conventional process is used to prepare the bio-based Flame retardant shading masterbatch;

[0047] Blowing the bio-based flame retardant and shading masterbatch according to the conventional film blowing process set by the film blowing factory to obtain the intermediate layer;

[0048] Disperse 0.2 kg of...

Embodiment 2

[0053] Calculated by mass, weigh 5 kg of Degussa NEROX 600 high-pigment carbon black, 1.0 kg of 2,4-dihydroxybenzophenone derivatives, 3 kg of [(6-oxy-(6H)-dibenzo- (CE)(1,2)-oxophosphahexan-6-one)methyl]-succinic acid (DOPO-DDP), 15 kg microencapsulated red phosphorus, 5 kg melamine borate, 0.6 kg horse Lilylic anhydride grafted polypropylene, 0.5 kg antioxidant (2,6-di-tert-butyl-4-methylphenol), 1.0 kg tris[dodecyl]phosphite and tris[hexadecyl] ] Phosphite, 60 kg of polypropylene, 25 kg of hydroxypropyl starch ether (HPS), after the materials are uniformly mixed in the mixer, they are added to the twin-screw extruder, extruded, and the conventional process is used to prepare the bio-based Flame retardant shading masterbatch;

[0054] Blowing the bio-based flame retardant and shading masterbatch according to the conventional film blowing process set by the film blowing factory to obtain the intermediate layer;

[0055] Heat and melt the PUR hot-melt adhesive, and evenly di...

Embodiment 3

[0060] Calculated by mass, weigh 5 kg of Degussa NEROX 600 high-pigment carbon black, 0.6 kg of 2,4-dihydroxybenzophenone derivatives, 4 kg of diphenoxyphosphate aniline (DPPP), and 15 kg of microcapsules Red phosphorus, 5 kg melamine borate, 0.6 kg starch graft copolymer, 0.5 kg antioxidant (2,6-di-tert-butyl-4-methylphenol), 1.0 kg tris[dodecyl ] phosphite and tris[hexadecyl] phosphite, 60 kg of polypropylene, 25 kg of hydroxypropyl starch ether (HPS), after the materials are uniformly mixed in the mixer, they are added to the twin-screw extruder , extrusion, using conventional technology to prepare bio-based flame retardant shading masterbatch;

[0061] Blowing the bio-based flame retardant and shading masterbatch according to the conventional film blowing process set by the film blowing factory to obtain the intermediate layer;

[0062] Heat and melt the PUR hot-melt adhesive, disperse 0.3 kg of resorcinol tetrakis (2,6-xylyl) diphosphate (XDP) evenly in 1 kg of PUR hot-m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com