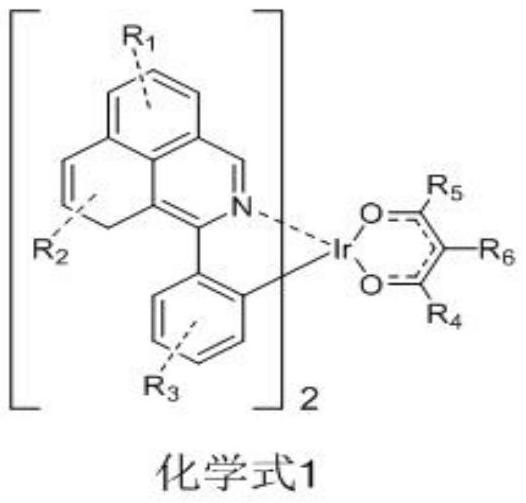

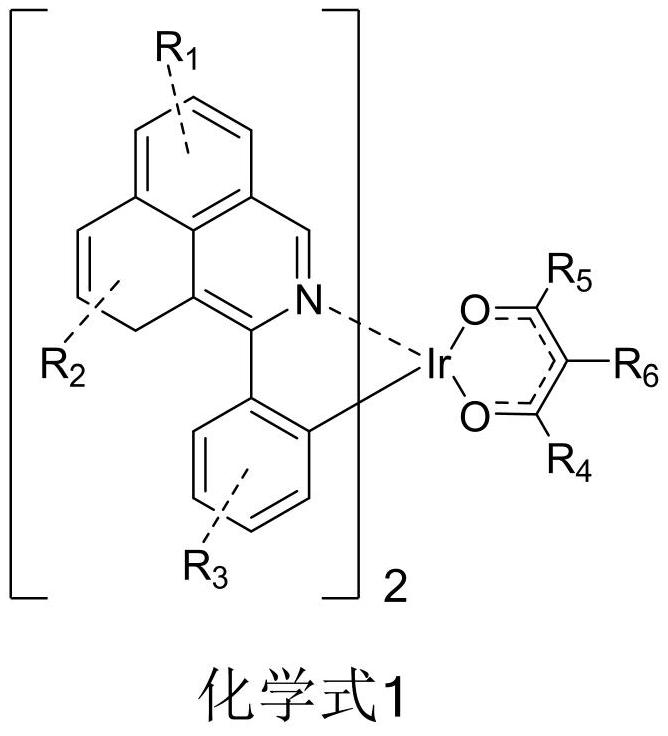

Iridium complex electroluminescent material, preparation method and application thereof

An electroluminescent material and luminescent technology, applied in the direction of luminescent materials, chemical instruments and methods, circuits, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

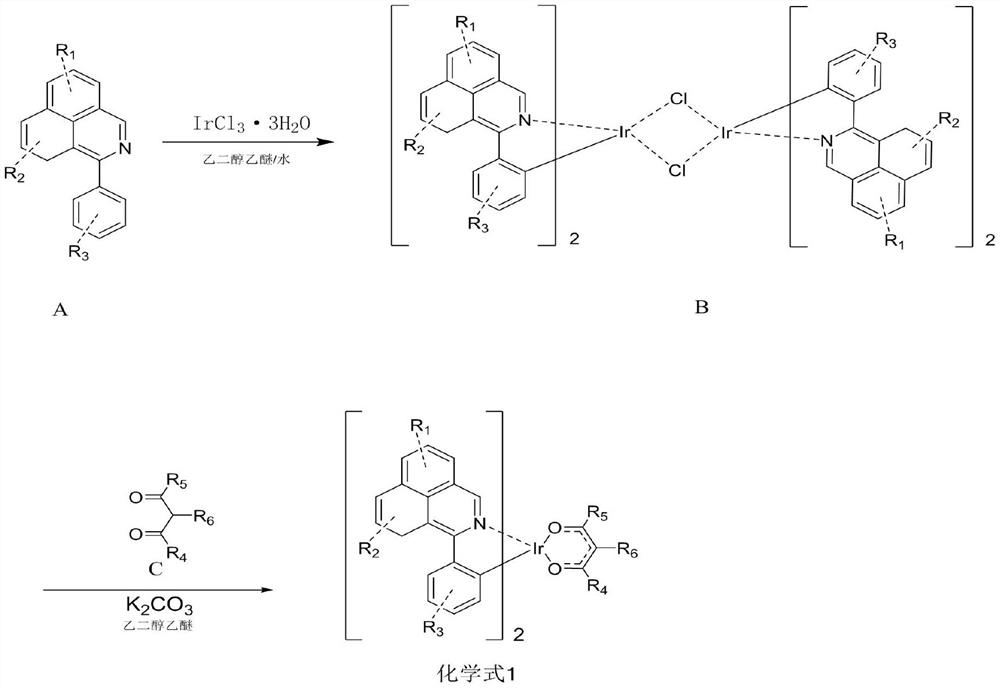

[0063] Embodiment 1 prepares compound F001

[0064]

[0065] Step 1. Under nitrogen protection system, weigh A-001 (73.70mmol, 20g), IrCl3 3H2O (24.57mmol, 8.66g) into the reaction system, add a mixed solution of 600mL ethylene glycol ether and 200mL pure water , refluxed under the protection of nitrogen for 24 hours, then cooled to room temperature, and a precipitate was precipitated, and the precipitate was filtered by suction, washed and dried with water, absolute ethanol, and petroleum ether in sequence to obtain the bridging ligand B-001 (11.2g, Yield 59.3%).

[0066] Step 2. Weigh intermediate B-001 (7.29mmol, 11.2g), add ligand C-001 (21.86mmol, 2.19g), then add ethylene glycol ether 250mL and potassium carbonate (72.88mmol, 10.07 g), under the protection of nitrogen, stirred at 120°C for 24 hours, suction filtered, washed with alcohol, dried, and used dichloromethane as a solvent, followed by silica gel column chromatography, and the filtrate was concentrated and s...

Embodiment 2

[0072] Embodiment 2 prepares compound F004

[0073]

[0074] Step 1. Under the nitrogen protection system, weigh A-004 (69.12mmol, 20g), IrCl 3 ·3H 2 O (23.04mmol, 8.12g) was put into the reaction system, a mixed solution of 600mL ethylene glycol ether and 200mL pure water was added, refluxed for 24 hours under the protection of nitrogen, and then cooled to room temperature, a precipitate was precipitated, the precipitate was suction filtered, and water , absolute ethanol, and petroleum ether were washed and dried in turn to obtain a red powder of bridging ligand B-004 (11.7 g, yield 63.13%).

[0075] Step 2. Weigh intermediate B-004 (7.27mmol, 11.7g), add ligand C-004 (21.82mmol, 2.18g), then add ethylene glycol ether 250mL and potassium carbonate (72.73mmol, 10.05 g), under the protection of nitrogen, stirred at 120°C for 24 hours, suction filtered, washed with alcohol, dried, used dichloromethane as solvent, and used silica gel column chromatography. The filtrate was c...

Embodiment 3

[0079] Embodiment 3 prepares compound F010

[0080]

[0081] Step 1. Under the nitrogen protection system, weigh A-010 (66.59mmol, 20g), IrCl 3 ·3H 2 O (22.2mmol, 7.83g) was put into the reaction system, a mixed solution of 600mL ethylene glycol ether and 200mL pure water was added, refluxed for 24 hours under the protection of nitrogen, and then cooled to room temperature, a precipitate was precipitated, and the precipitate was suction filtered, and water , absolute ethanol, and petroleum ether were washed and dried in turn to obtain a red powder of bridging ligand B-010 (11.6 g, yield 63.24%).

[0082] Step 2. Weigh the intermediate B-010 (7.02mmol, 11.6g), add the ligand C-010 (21.06mmol, 2.11g), then add ethylene glycol ether 250mL and potassium carbonate (70.19mmol, 9.70 g), under the protection of nitrogen, stirred at 120°C for 24 hours, suction filtered, washed with alcohol, dried, and used dichloromethane as a solvent, followed by silica gel column chromatography,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com