Pickling agent used for copper and copper alloy finishing process

A pickling agent and copper alloy technology, which is applied in the field of copper and copper alloy finishing, can solve problems such as uneven brightness and affecting pickling effect, achieve good cleaning effect, improve pickling effect, and shorten the process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

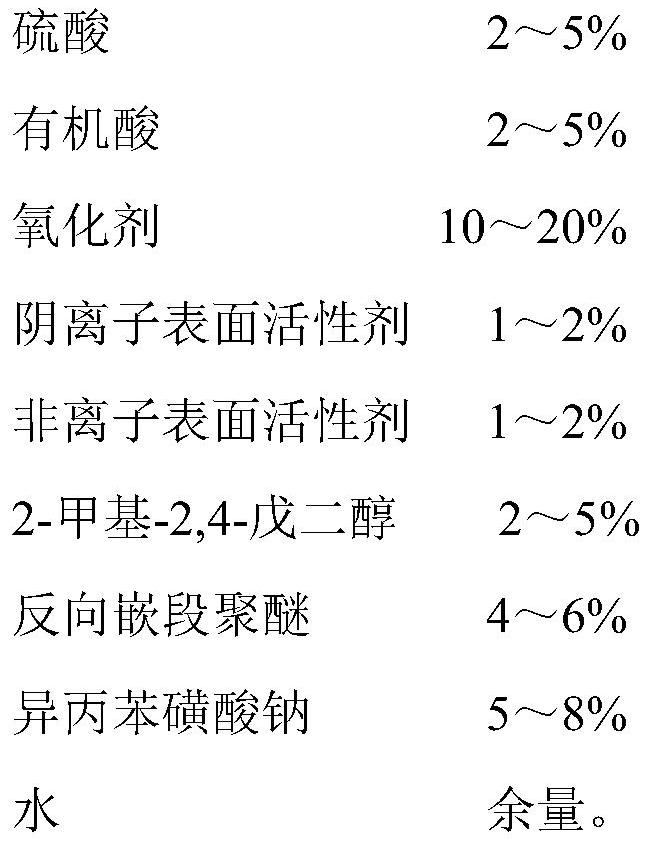

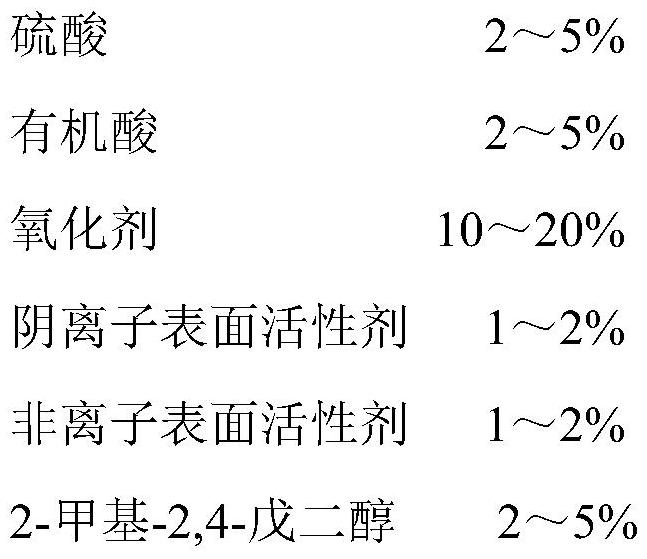

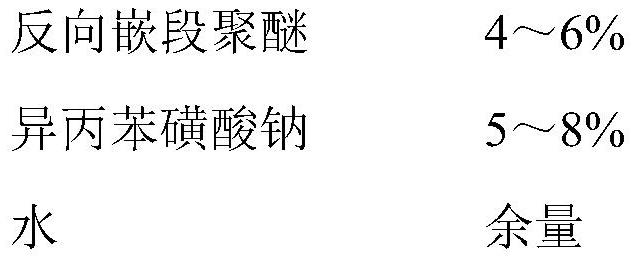

Embodiment 1

[0037] A kind of pickling agent for copper and copper alloy finishing process, according to mass percentage, composition is as follows: sulfuric acid 2%, citric acid 2%, potassium hydrogen persulfate double salt 20%, sodium dodecylbenzene sulfonate 1 %, NP-10 2%, 2-methyl-2,4-pentanediol 5%, RPE 1720 6%, sodium cumene sulfonate 8%, and the balance is pure water.

[0038] Preparation method: take the material according to the above-mentioned raw material ratio, and stir evenly.

[0039] When in use, add water to the above-mentioned pickling agent to form an aqueous pickling agent solution with a mass concentration of 30%, and then add abrasives and corresponding amounts of copper and copper alloy parts to the polishing machine for 5 minutes, and then perform polishing and polishing after washing with water. Anti-corrosion treatment, and then after washing and drying, the appearance inspection is carried out.

[0040] Compared with the standard sample, the treated sample has no...

Embodiment 2

[0042] A kind of pickling agent for copper and copper alloy finishing process, according to mass percentage, composition is as follows: sulfuric acid 2%, citric acid 2%, potassium persulfate 10%, sodium dodecylbenzene sulfonate 2%, NP -10 1%, 2-methyl-2,4-pentanediol 5%, RPE17204%, sodium cumene sulfonate 8%, the balance is pure water.

[0043] Preparation method: take the material according to the above-mentioned raw material ratio, and stir evenly.

[0044] When in use, add water to the above-mentioned pickling agent to make an aqueous pickling agent solution with a mass concentration of 30%, then put abrasives and corresponding amounts of copper and copper alloy parts into the finishing machine and roll for 5 minutes, and then carry out polishing and anti-corrosion after washing. treatment, and then washed and dried for appearance inspection.

[0045] Compared with the standard sample, the treated sample has no obvious color difference (⊿E≤1.5), is uniform and bright, and ...

Embodiment 3

[0047] A kind of pickling agent for copper and copper alloy finishing process, according to the mass percentage, the composition is as follows: sulfuric acid 5%, phytic acid 5%, sodium persulfate 20%, sodium dodecylbenzene sulfate 1%, JFC 2 %, 2-methyl-2,4-pentanediol 2%, RPE17406%, sodium cumene sulfonate 8%, and the balance is pure water.

[0048] Preparation method: take the material according to the above-mentioned raw material ratio, and stir evenly.

[0049] When in use, add water to the above-mentioned pickling agent to make an aqueous pickling agent solution with a mass concentration of 30%, then put abrasives and corresponding amounts of copper and copper alloy parts into the finishing machine and roll for 5 minutes, and then carry out polishing and anti-corrosion after washing. treatment, and then washed and dried for appearance inspection.

[0050] Compared with the standard sample, the treated sample has no obvious color difference (⊿E≤1.5), is uniform and bright,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com