Preparation method for multifunctional pH-responsive type super-infiltration material and application in oil-water separation

A super-wetting and multi-functional technology, applied in the direction of liquid separation, separation methods, chemical instruments and methods, etc., to achieve the effect of mild reaction conditions, low equipment requirements, and uniform surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The preparation process of the present invention is as follows: dissolving silane coupling agent, compound containing long carbon chain and acrylic acid in alcohol solvent, adding azobisisobutyronitrile, stirring and reacting at 70-90°C for 8-9 hours to obtain Mixed solution; put the pretreated clean fabric in the mixed solution, add inorganic micro-nano particles under stirring conditions, and ultrasonically disperse for 20-30 minutes; then add tetraethyl orthosilicate or butyl titanate, and heat After reacting for 1.5-2 hours, the fabric is taken out, and then dried at 80-100° C. for 1-2 hours to obtain a functionalized fabric with pH response.

[0040] Wherein, the silane coupling agent is vinyltrimethoxysilane or 3-(trimethoxysilane) propyl acrylate.

[0041] Compounds containing long carbon chains are tridecyl methacrylate, dodecyl methacrylate or hexadecyl methacrylate.

[0042] The alcoholic solvent is ethanol or methanol.

[0043] The mass ratio of the silane ...

Embodiment 1

[0051] The preparation method of the present embodiment comprises the following steps:

[0052] Step 1. Dissolve 0.28g of vinyltrimethoxysilane, 0.30g of tridecyl methacrylate and 0.32g of acrylic acid in 15mL of ethanol solvent, add 0.025g of azobisisobutyronitrile, and stir at 75°C React 9h, obtain mixed solution;

[0053] Step 2, soaking the pretreated clean fabric in the mixed solution of step 1;

[0054] Step 3: Add 0.20 g of micron-sized silicon dioxide and 0.10 g of nano-sized magnesium oxide particles to the mixed solution in step 1 under stirring conditions, and disperse ultrasonically for 20 minutes;

[0055] Step 4: Add 1.2 mL of tetraethyl orthosilicate to the reacted solution in Step 3, react at 50° C. for 2 hours, take out the fabric, and then dry it at a constant temperature of 80° C. for 2 hours to obtain a functionalized fabric with pH response.

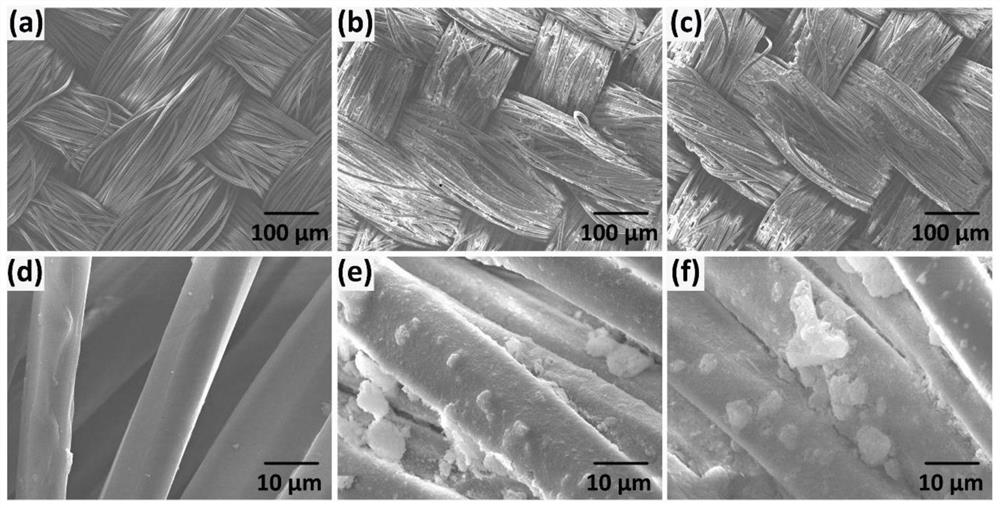

[0056] figure 1 It is the scanning electron micrographs of the original fabric, the modified fabric and the mod...

Embodiment 2

[0066] Step 1. Dissolve 0.25g of vinyltrimethoxysilane, 0.28g of tridecyl methacrylate and 0.30g of acrylic acid in 10mL of ethanol solvent, add 0.020g of azobisisobutyronitrile, and stir at 70°C Reaction 8h, obtain mixed solution;

[0067] Step 2, soaking the pretreated clean fabric in the mixed solution of step 1;

[0068] Step 3. Add 0.18 g of micron-sized silicon dioxide and 0.13 g of nano-sized magnesium oxide particles to the mixed solution in step 1 under stirring conditions, and ultrasonically disperse for 30 minutes;

[0069] Step 4: Add 1.0 mL tetraethyl orthosilicate to the reacted solution in Step 3, react at 55° C. for 1.5 h, take out the fabric, and then dry it at 90° C. for 1 h to obtain a functionalized fabric with pH response.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com