Method for activating ferric ferricyanide and zinc ion battery prepared by method

A zinc-ion battery, iron ferricyanide technology, applied in battery electrodes, secondary batteries, electrolyte immobilization/gelation, etc., can solve the problem of low rate performance, specific capacity blocking PBA-cathode, rate performance capacity reduction, etc. problems, to achieve the effects of high ionic conductivity, excellent antifreeze function, and excellent cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] This embodiment provides an antifreeze gel electrolyte, which is prepared through the following steps:

[0044] 1) Prepare 15mL 21M high-concentration bistrifluoromethanesulfonimide zinc-lithium electrolyte;

[0045] 2) Add 3 g of acrylamide to the high-concentration bistrifluoromethanesulfonimide zinc-lithium electrolyte, and stir at room temperature for 30 minutes;

[0046] 3) After adding 0.5 mg ammonium persulfate and 0.2 mg dimethylacrylamide, stir at room temperature for 30 min;

[0047] 4) Inject the product of step 3) into an ordinary glass mold, and place it in an oven at 70°C for 2 hours of polymerization;

[0048] 5) Remove the mold to obtain the final antifreeze gel electrolyte.

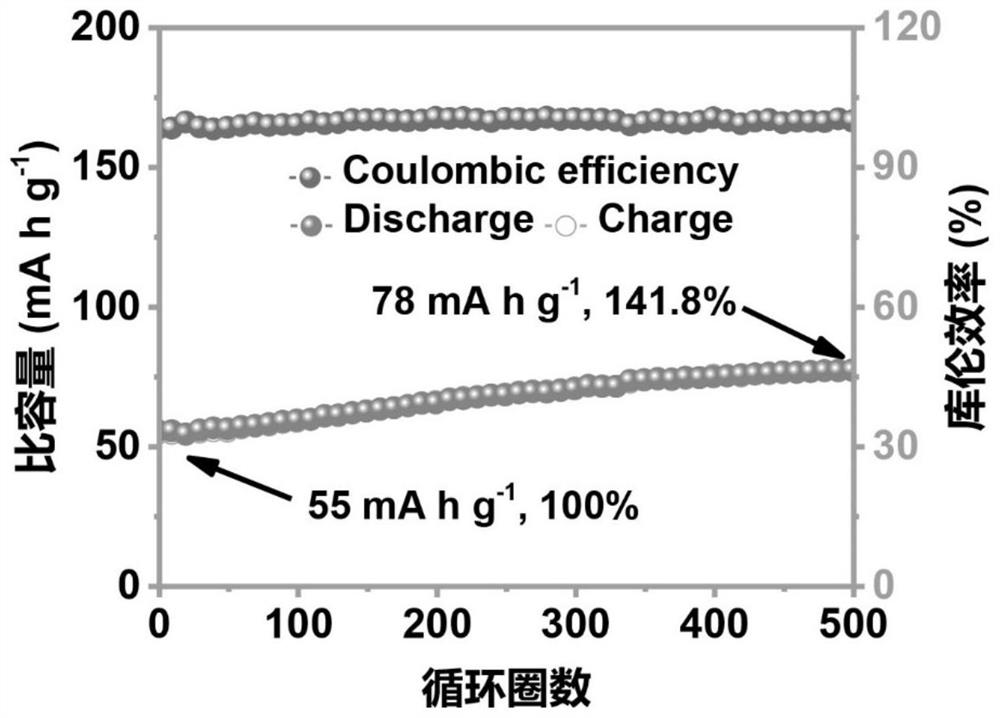

[0049] The present embodiment provides a kind of activation method of ferricyanide, it may further comprise the steps:

[0050] (1) The newly assembled Zn-FeHCF battery was left to stand at room temperature for 1 hour, wherein the electrolyte was the antifreeze gel electrolyte p...

Embodiment 2

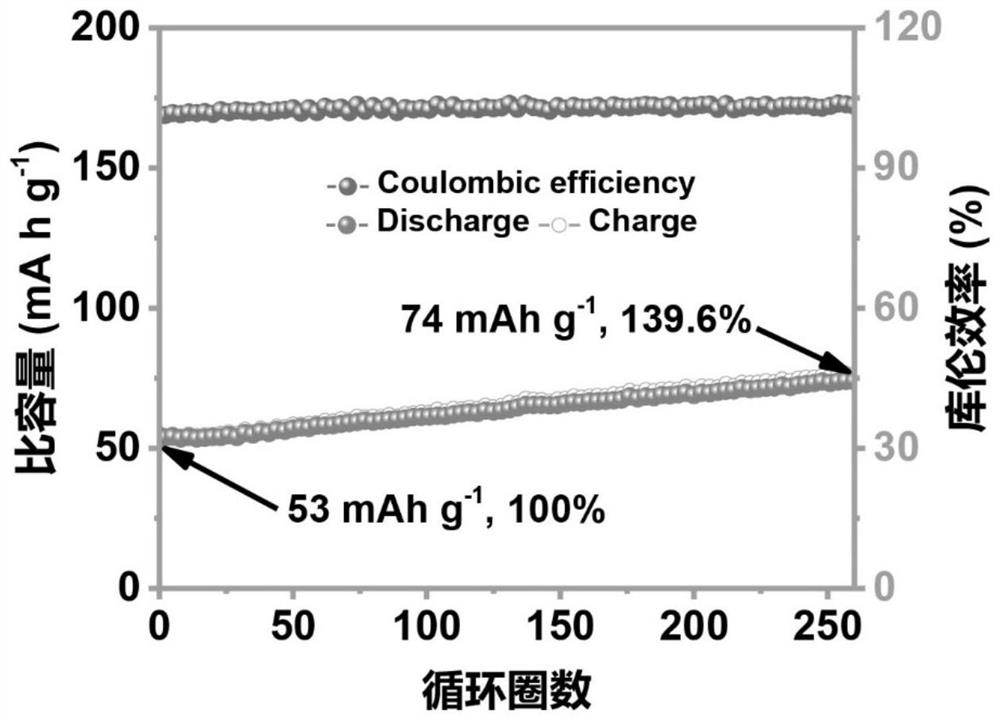

[0056] The present embodiment provides a kind of activation method of ferricyanide, it may further comprise the steps:

[0057] (1) The newly assembled Zn-FeHCF battery was left to stand at room temperature for 1 hour, and the electrolyte was the antifreeze gel electrolyte prepared in embodiment 1;

[0058] (2) After standing still, perform a high-voltage scan on the Zn-FeHCF battery on the blue battery test system, with a current density of 2A g -1 , the voltage upper limit is 2.3V;

[0059] (3) After the high-voltage scan, the Zn-FeHCF battery is programmed to stand still on the blue electric battery test system, and the standstill time is 1s;

[0060] (4) After the program is left still, the Zn-FeHCF battery is programmed to discharge on the blue electric battery test system, and the current density is 1A g -1 , the voltage lower limit is 0.01V; the battery completes a high-voltage scanning cycle after programmed discharge, and continues for 260 cycles to complete the act...

Embodiment 3

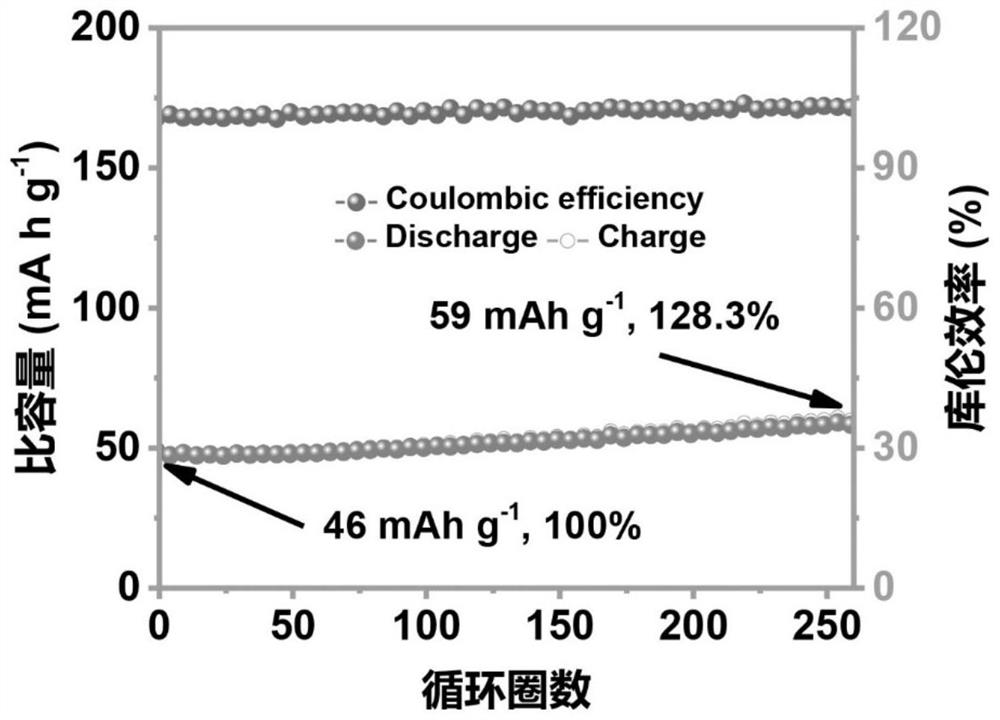

[0063] The present embodiment provides a kind of activation method of ferricyanide, it may further comprise the steps:

[0064] (1) The newly assembled Zn-FeHCF battery was left to stand at room temperature for 1 hour, and the electrolyte was the antifreeze gel electrolyte prepared in embodiment 1;

[0065] (2) After standing still, perform a high-voltage scan on the Zn-FeHCF battery on the blue electric battery test system, and the current density is 1A g -1 , the voltage upper limit is 2.3V;

[0066] (3) After the high-voltage scan, the Zn-FeHCF battery is placed on the blue electric battery testing system, and the standing time is 5s;

[0067] (4) After the program is left still, the Zn-FeHCF battery is programmed to discharge on the blue electric battery test system, and the current density is 1A g -1 , the voltage lower limit is 0.01V; the battery completes a high-voltage scanning cycle after programmed discharge, and continues for 500 cycles to complete the activation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com