Electrocatalyst for methanol fuel cell and preparation method thereof

A methanol fuel cell and electrocatalyst technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of poor dispersion and uniformity of bimetallic composite materials, inconspicuous catalytic performance of a single transition metal, and difficult distribution of material particles. , to achieve the effect of promoting the interface electrocatalytic reaction, improving the catalytic effect and good catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

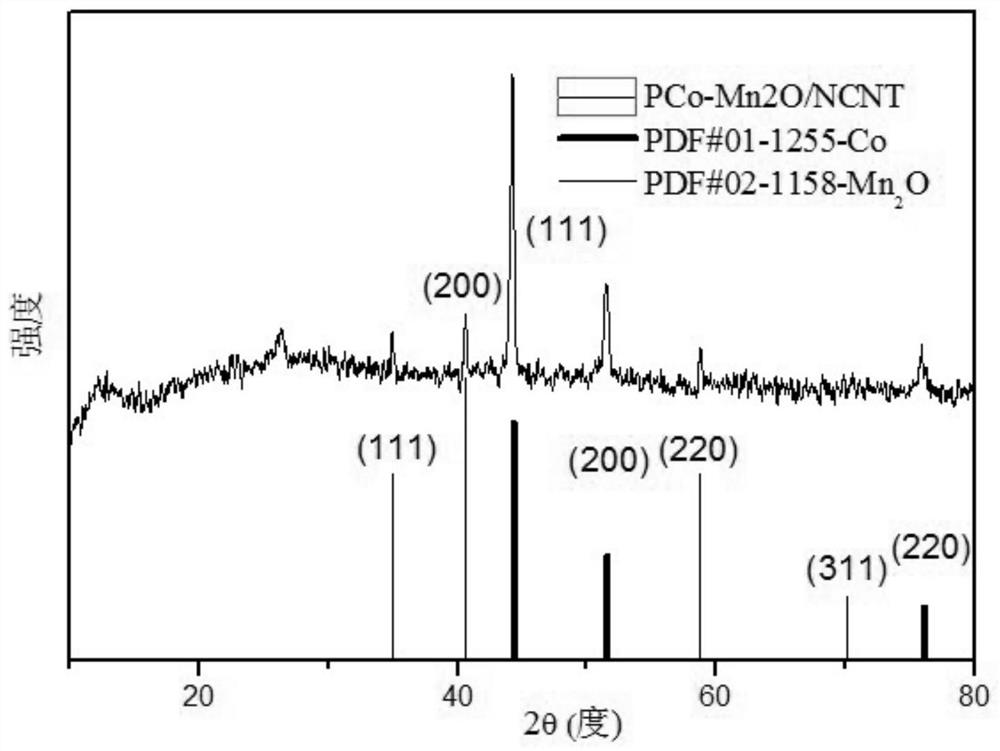

[0024] Example 1 Co-Mn 2 Preparation of O / NCNTs electrocatalyst

[0025] (1) Disperse 0.001mol of manganese acetate and 0.005mol of cobalt nitrate hexahydrate in 50mL of methanol solution, and stir to obtain solution A;

[0026] (2) Add 0.04mol dicyandiamide to solution A, continue to stir and mix to obtain a homogeneous mixture B;

[0027] (3) Transfer the mixture B to an oven for drying at 80°C for 24 hours, and obtain the product C after drying;

[0028] (4) Grind the product C evenly and place it in a tube furnace for calcination. The calcination temperature is 800°C, the heating rate is 2°C / min, and the holding time is 4h. After calcination, Co-Mn 2 O / NCNTs nanomaterials.

[0029] The obtained Co-Mn 2 4 mg of O / NCNTs nanomaterials was added to the mixed solution of ethanol and water (V 乙醇 :V 水 =1:3, a total of 1 ml), and then add 15 microliters of mold solution with a mass fraction of 5%. Sonicate to make it completely dispersed, and take 20 microliters of the comp...

Embodiment 2

[0032] Example 2 Co-Mn 2 Preparation of O / NCNTs electrocatalyst

[0033] (1) Disperse 0.001mol of manganese acetate and 0.005mol of cobalt nitrate hexahydrate in 50mL of methanol solution, and stir to obtain solution A;

[0034] (2) Add 0.04mol dicyandiamide to solution A, continue to stir and mix to obtain a homogeneous mixture B;

[0035] (3) Transfer the mixture B to an oven for drying at 80°C for 48 hours, and obtain the product C after drying;

[0036] (4) Grind the product C evenly and place it in a tube furnace for calcination. The calcination temperature is 750°C, the heating rate is 2°C / min, and the holding time is 4h. After calcination, Co-Mn 2 O / NCNTs nanomaterials.

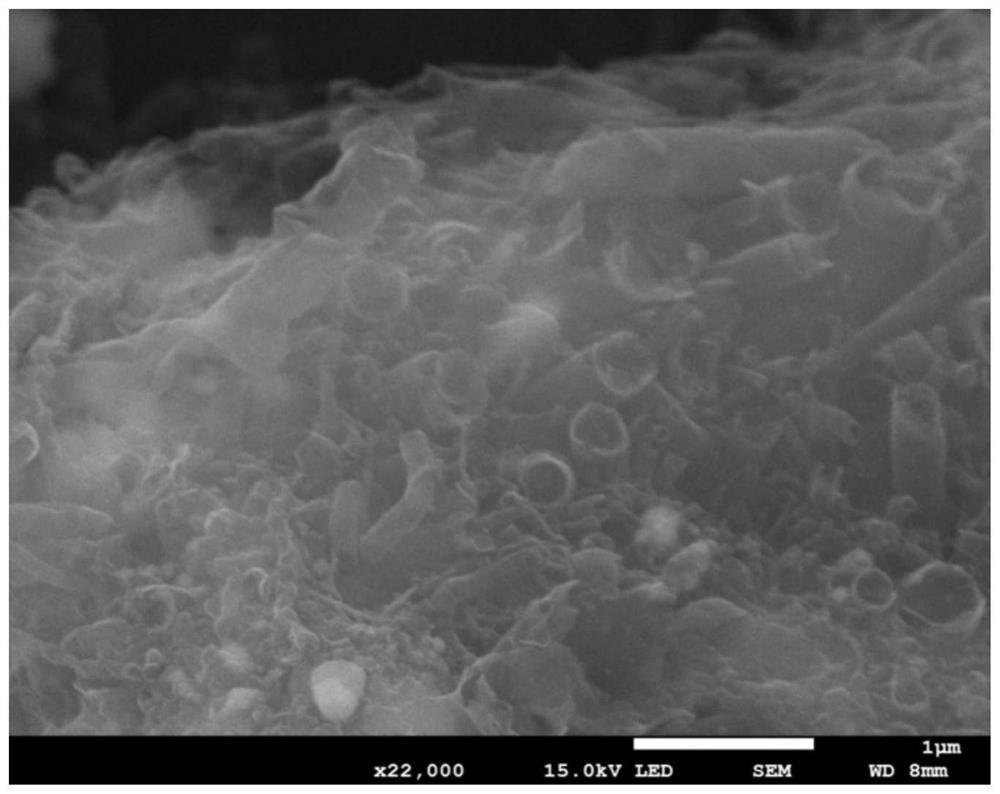

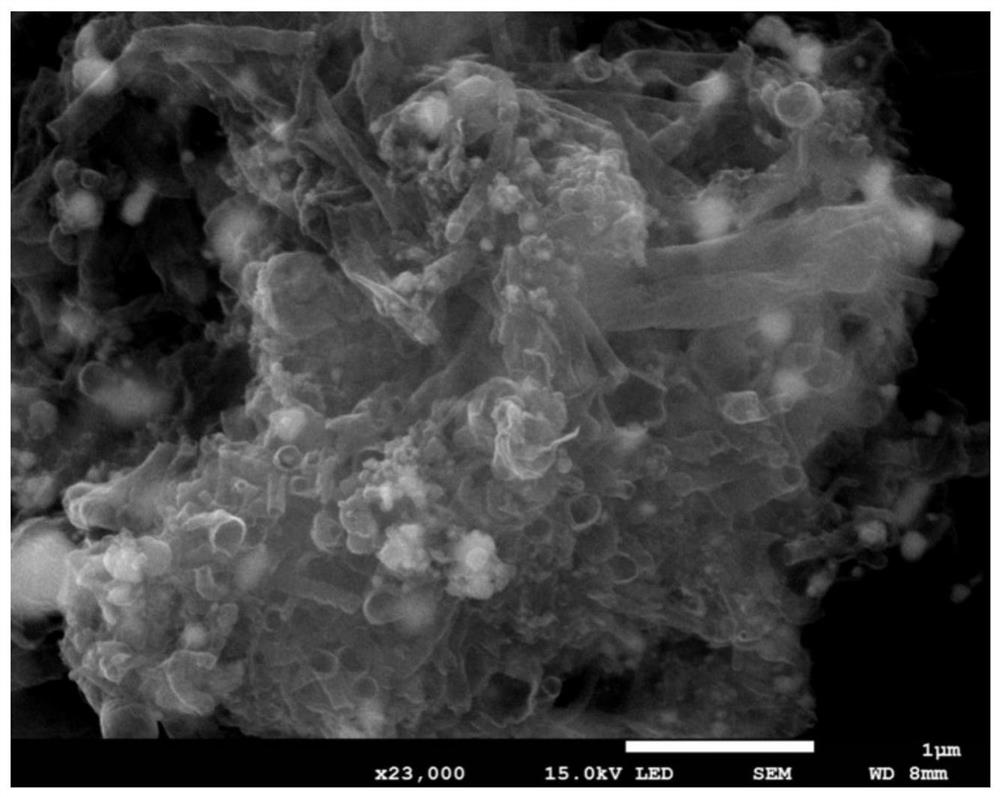

[0037] Such as image 3 As shown, the Co-Mn prepared in this example 2 O / NCNTs nanomaterials present a tubular structure, Co / Mn 2The O nanoparticle structure is uniformly distributed in the carbon nanotubes, and the diameter of the tubes is about 100 nm. The formation of nanoparticles may be due...

Embodiment 3

[0038] Example 3 Co-Mn 2 Preparation of O / NCNTs electrocatalyst

[0039] (1) Disperse 0.001mol of manganese acetate and 0.005mol of cobalt nitrate hexahydrate in 50mL of methanol solution, and stir to obtain solution A;

[0040] (2) Add 0.04mol dicyandiamide to solution A, continue to stir and mix to obtain a homogeneous mixture B;

[0041] (3) transfer the mixture B to an oven for 24 hours at 90° C., and obtain the product C after drying;

[0042] (4) Grind product C evenly and place it in a tube furnace for calcination. The calcination temperature is 850°C, the heating rate is 2°C / min, and the holding time is 4h. After calcination, Co-Mn 2 O / NCNTs nanomaterials.

[0043] Such as Figure 4 As shown, catalysts have different oxidation effects on methanol catalysts at different scan rates. Utilize cyclic voltammetry to measure the Co-Mn obtained in the present embodiment 2 Electrocatalytic performance of O / NCNTs electrocatalysts towards methanol. With the increase of sca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com