A new type of environmentally friendly industrial waste gas treatment equipment

A technology for industrial waste gas and treatment equipment, applied in the direction of human health protection, climate sustainability, air quality improvement, etc., can solve the problems of complex industrial waste gas composition, increase of reaction reagents, unsolved problems of pollutants requiring secondary treatment, etc. , to achieve the effect of increasing the single adsorption capacity, ensuring the flow condition and increasing the stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

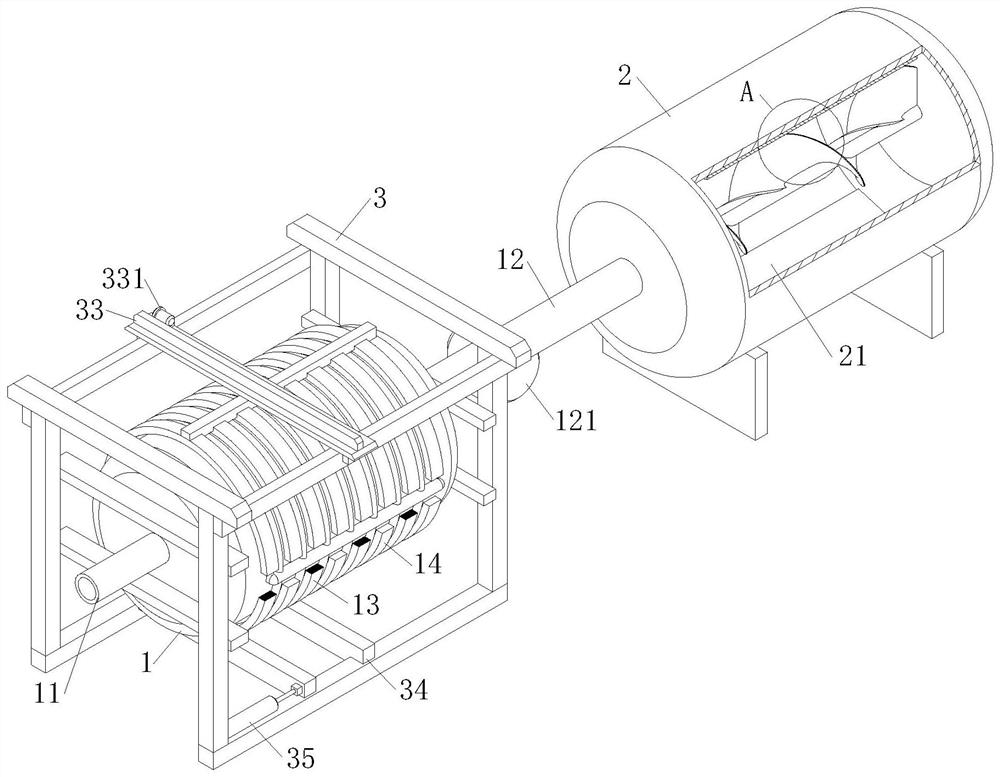

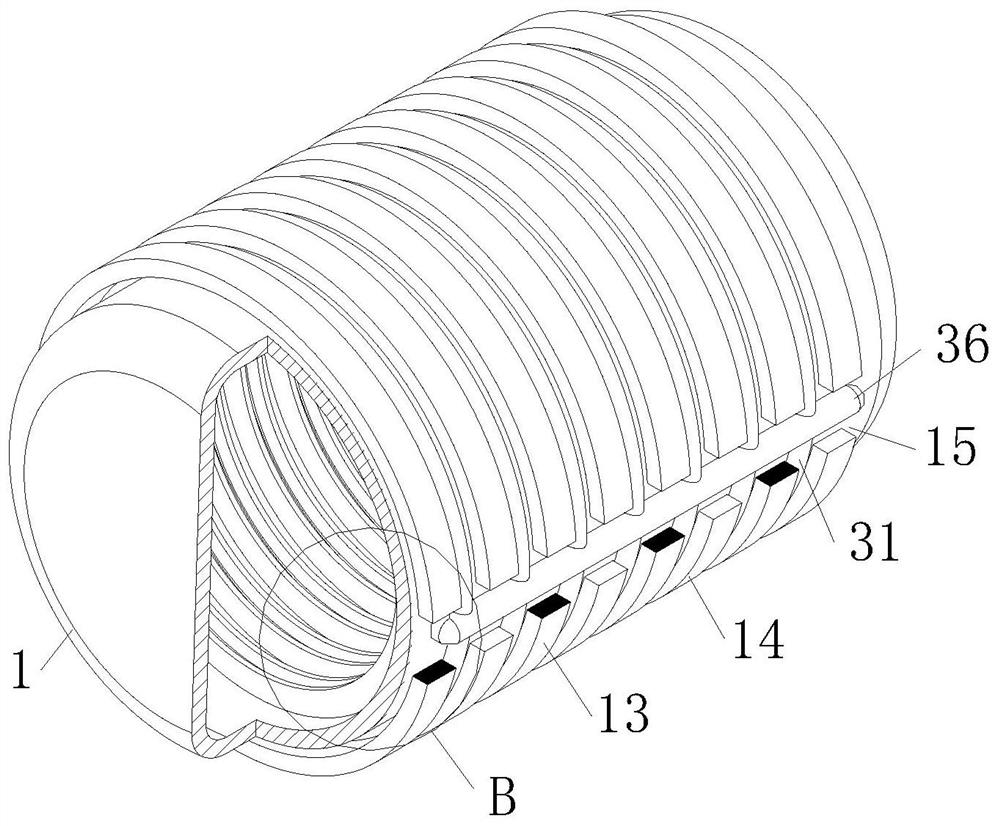

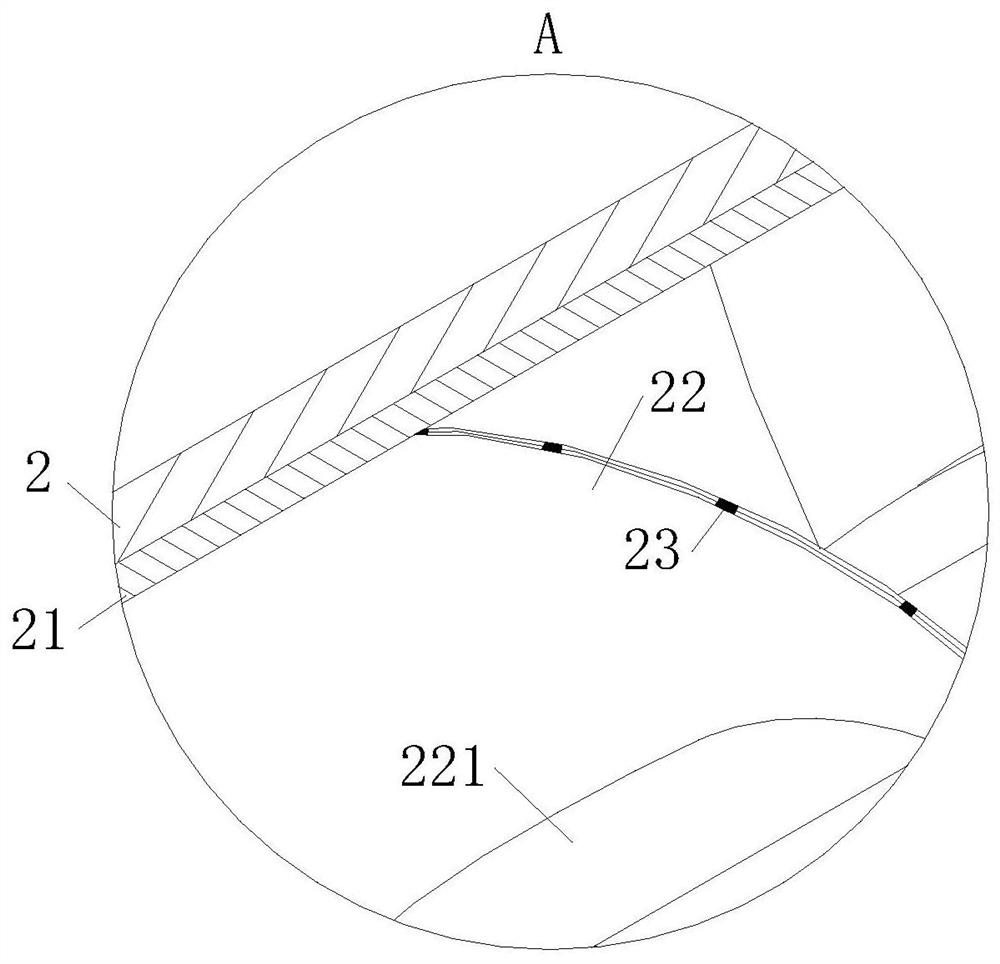

[0024] As an embodiment of the present invention, a bracket 3 is provided on the outer side of the dust removal cylinder 1, and both ends of the dust removal cylinder 1 are fixed on the bracket 3; the bracket 3 is provided with a cylindrical grid ring 31, and the grid ring 31 The cylindrical surface of the dust removal cylinder 1 extends into the interior, and the grid ring 31 is provided with annular grooves 32 arranged in layers on the inner wall of the dust removal cylinder 1; the annular grooves 32 are affected by the electric field of the negative ring plate 13; When the soot particles are adsorbed, the electric charge between the negative ring plate 13 and the positive ring plate 14 causes the soot particles to adhere to the inner wall of the dust collector 1. After more soot particles adhere to the dust collector 1, the adsorption of the soot particles will be lost. It is necessary to deal with the accumulated soot particles, which reduces the running time of the dust re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com