TPU modified impact-resistant transparent composite material and preparation method thereof

A composite material and impact-resistant technology, which is applied in the field of TPU modified impact-resistant transparent composite materials and its preparation, can solve the problems of not being able to show the mechanical advantages of the shell structure, damage to the sheet structure, and insufficient energy absorption, etc., to achieve high transparency Performance and mechanical strength, high impact resistance, and the effect of expanding the range of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

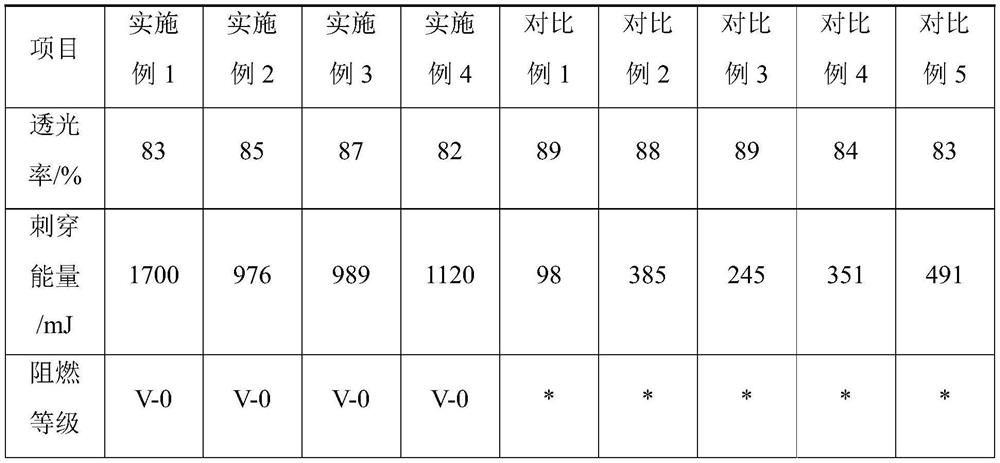

Embodiment 1

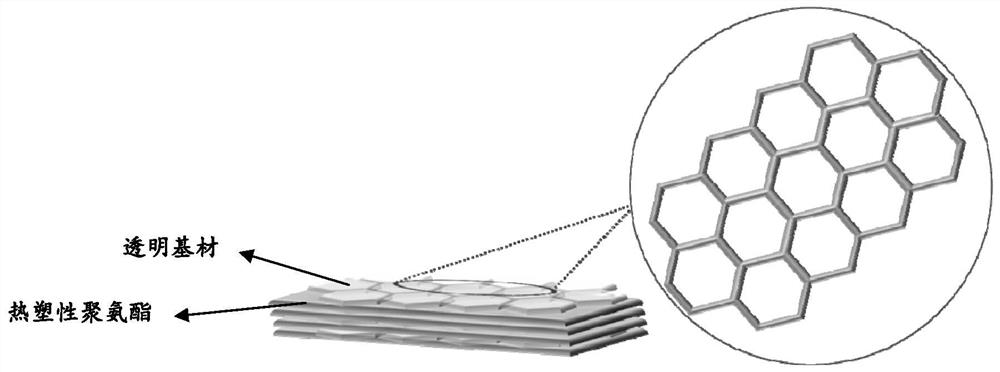

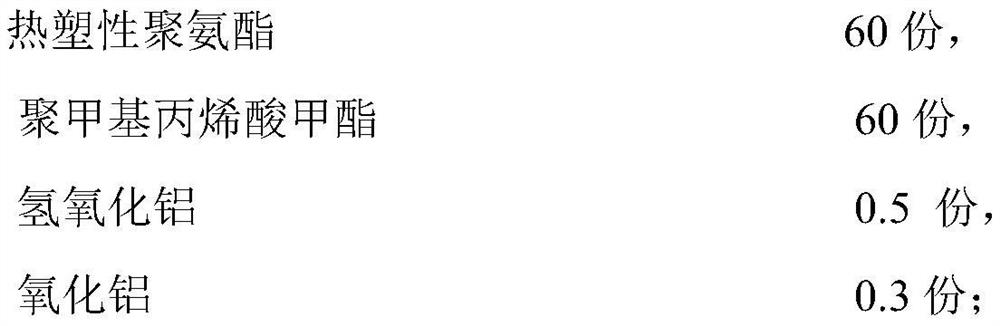

[0029] The TPU modified impact-resistant transparent composite material is calculated in parts by mass, and the raw material ratio is as follows:

[0030] Thermoplastic polyurethane 50 parts,

[0031] 50 pieces of glass,

[0032] 0.5 parts of aluminum hydroxide;

[0033] The thermoplastic polyurethane is polyester type injection molding grade 70A product T3170 produced by Shandong Yinuowei Polyurethane Co., Ltd.

[0034] The preparation method is as follows:

[0035] (1) Carve 50 pieces of glass into a hexagonal structure similar to the graphene structure by using a focused pulsed laser beam. The engraved lines eventually need certain connections to avoid initial separation, and they must be able to separation;

[0036] (2) Stir 50 parts of thermoplastic polyurethane and 0.5 parts of aluminum hydroxide particles to melt evenly at 200±10°C, and spread the mixed melt (scratch coater) onto a large-area polytetrafluoroethylene flat plate (room temperature Bottom), before the ...

Embodiment 2

[0039] The TPU modified impact-resistant transparent composite material is calculated in parts by mass, and the raw material ratio is as follows:

[0040] 60 parts of thermoplastic polyurethane,

[0041] Polyethylene 60 parts,

[0042] 0.8 parts of aluminum oxide;

[0043] The thermoplastic polyurethane is polyester extrusion grade 85A product E3385 produced by Shandong Yinuowei Polyurethane Co., Ltd.

[0044] The preparation method is as follows:

[0045] (1) Carve 60 parts of polyethylene into a hexagonal structure similar to a graphene structure through a focused pulsed laser beam. The engraved lines need a certain connection to avoid initial separation, and they must be able to separation;

[0046] (2) Stir 60 parts of thermoplastic polyurethane and 0.8 parts of aluminum hydroxide particles to melt evenly at 210±10°C, and spread the mixed melt (scratch coater) onto a large-area polytetrafluoroethylene flat plate while it is hot (room temperature Bottom), before the me...

Embodiment 3

[0049] The TPU modified impact-resistant transparent composite material is calculated in parts by mass, and the raw material ratio is as follows:

[0050] Thermoplastic polyurethane 70 parts,

[0051] Polypropylene 70 parts,

[0052] Magnesium hydroxide 1 part;

[0053] The thermoplastic polyurethane is polyester extrusion grade 60D product E298 produced by Shandong Yinuowei Polyurethane Co., Ltd.

[0054] The preparation method is as follows:

[0055] (1) Carve 70 parts of polypropylene into a hexagonal structure similar to graphene structure through a focused pulsed laser beam. The engraved lines eventually need certain connections to avoid initial separation, and they must be able to separation;

[0056] (2) Stir 70 parts of thermoplastic polyurethane and 1 part of aluminum hydroxide particles to melt evenly at 220±10°C, and spread the mixed melt (scratch coater) onto a large-area polytetrafluoroethylene flat plate while it is hot (room temperature Bottom), before the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

| Transmittance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com