Method and device for separating methylal in polyoxymethylene dimethyl ether system

A technology for polymethoxydimethyl ether and methylal, which is applied in the field of rectification and separation, can solve the problems of high energy consumption for separation, limit the industrialization of technological processes, complicated separation process, etc., and can meet the requirements of purity, good economic benefits, The effect of simplifying the separation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

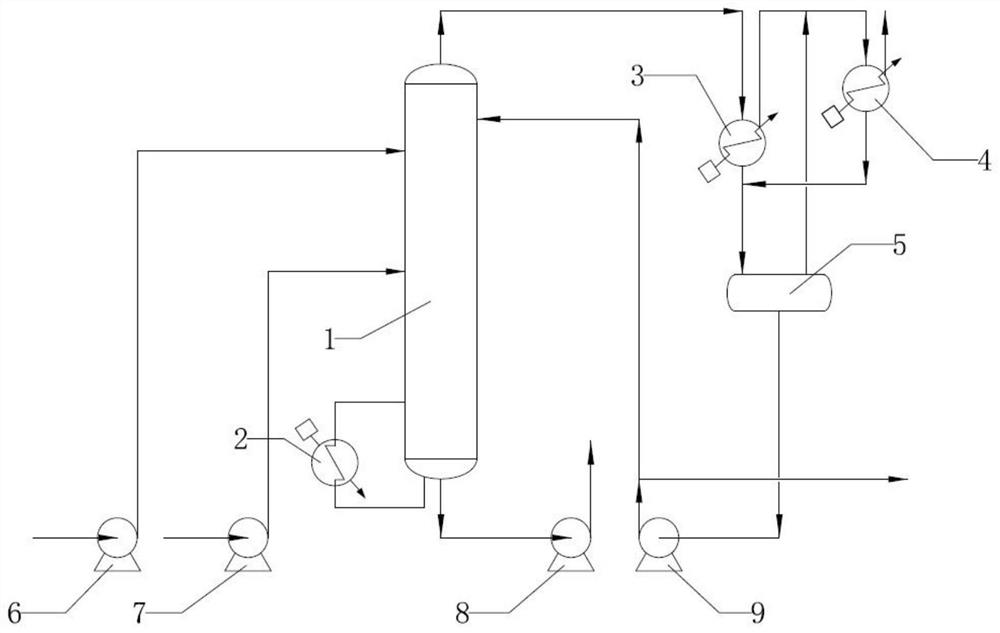

Image

Examples

Embodiment 1

[0037] A reactive extraction rectification separation of methylal, methanol, water, formaldehyde, paraformaldehyde and PODE 2 For the separation process of the mixture, the reactive extractive distillation column 1 has 11 theoretical plates. Using formaldehyde solution as a reactive extractant, formaldehyde solution and methylal, methanol, water, formaldehyde, paraformaldehyde and PODE 2 After the mixture is mixed, it is added from the 8th theoretical plate (the number of plates is from top to bottom), the ratio of formaldehyde / methanol is 2.3, and the amount of addition is 5000 kg / hr. The operating pressure of the reactive extractive distillation column is 101.3kPa, the top reflux ratio is 0.89, the top temperature is 42°C, the bottom temperature is 98.2°C, and the methylal product with a mass fraction of 99.0wt% is obtained at the top of the tower.

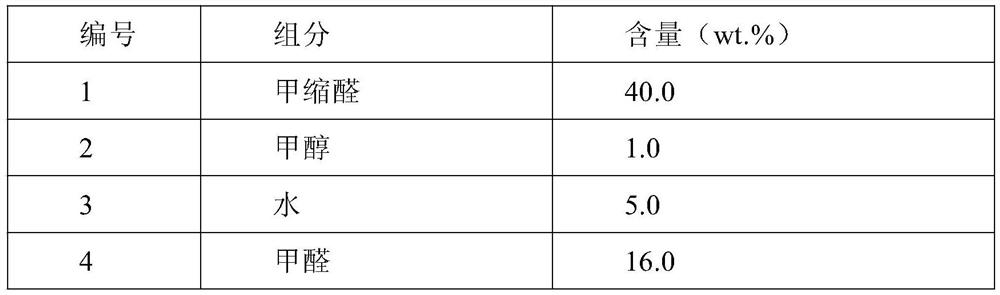

[0038] Feed composition as shown in the table

[0039] Numbering components Content (wt.%) 1 Methylal 4...

Embodiment 2

[0041] A reactive extraction rectification separation of methylal, methanol, water, formaldehyde, paraformaldehyde and PODE 2 For the separation process of the mixture, the reactive extractive distillation column 1 has 11 theoretical plates. Formaldehyde solution is used as the reaction extractant, and the formaldehyde solution is added from the third theoretical plate (the number of plates is from top to bottom). Methylal, methanol, water, formaldehyde, paraformaldehyde and PODE 2 After the mixture is mixed, it is added from the 8th theoretical plate (the number of plates is from top to bottom), the ratio of formaldehyde / methanol is 2.3, and the amount of addition is 5000 kg / hr. The operating pressure of the reactive extractive distillation column is 101.3kPa, the top reflux ratio is 0.89, the top temperature is 42°C, the bottom temperature is 98.2°C, and the methylal product with a mass fraction of 99.0wt% is obtained at the top of the tower.

[0042] The composition is as ...

Embodiment 3

[0045] A reactive extraction rectification separation of methylal, methanol, water, formaldehyde, paraformaldehyde and PODE 2 For the separation process of the mixture, the reactive extractive distillation column 1 has 11 theoretical plates. Using formaldehyde solution as a reactive extractant, formaldehyde solution and methylal, methanol, water, formaldehyde, paraformaldehyde and PODE 2 After the mixture is mixed, it is added from the 8th theoretical plate (the number of plates is from top to bottom), the formaldehyde / methanol ratio is 1.6, and the addition amount is 5000 kg / hr. The operating pressure of the reactive extractive distillation tower is 101.3kPa, the top reflux ratio is 2.0, the top temperature is 42°C, the bottom temperature is 98.2°C, and the top of the tower obtains a methylal product with a mass fraction of 99.6wt%.

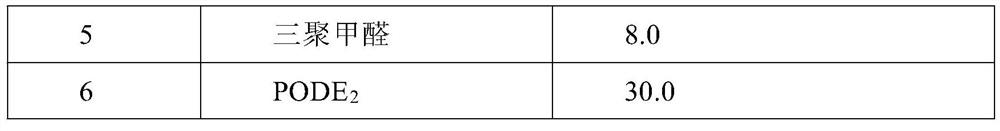

[0046] The composition is as shown in the table:

[0047]

[0048]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com