Synthesis method and application of waterborne polyurethane for microfiber impregnation

A technology of water-based polyurethane and synthesis method, which is applied in the direction of textiles and papermaking, can solve the problems of insufficient softness, poor temperature resistance, easy hydrolysis, etc., and achieve the effect of good resilience and soft hand feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

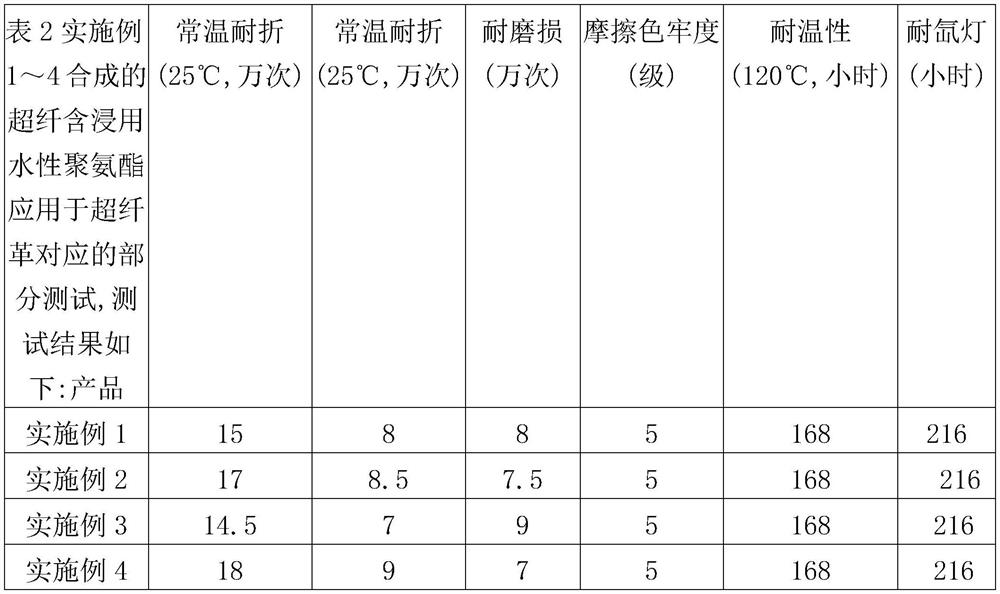

Examples

Embodiment 1

[0054] (1) First, add 100g polytetrahydrofuran ether glycol (PTMG2000) and 150g polypropylene glycol (PPG3000) to a 1000ml four-necked flask with electric stirring, thermometer, constant pressure funnel and vacuum pump, then turn on the electric stirrer, oil bath , Vacuum pump, start timing when the thermometer on the four-necked flask reaches 110°C, vacuum pressure ≤ -0.08MPa, keep the temperature at 110°C ~ 120°C, and vacuum dehydration for 3 hours under the conditions of pressure ≤ -0.08MPa.

[0055] (2) When the water content in the polyol is less than 0.05%, turn off the vacuum pump and reduce the temperature of the oil bath. When the temperature of the thermometer drops to 75°C, slowly add 77.8g of isophorone diisocyanate through the constant pressure funnel. Stir evenly, start to heat up, when the temperature reaches 90°C, start timing, and react at constant temperature for 1 hour. The -NCO content in the mixture was determined to reach the design value by titration. T...

Embodiment 2

[0060] (1) First, 100g polytetrahydrofuran ether glycol (PTMG2000), 100g polypropylene glycol (PPG3000) and 50g polypropylene glycol (PPG4000) were added to a 1000ml four-necked flask with electric stirring, thermometer, constant pressure funnel and vacuum pump, and then opened Electric stirrer, oil bath, vacuum pump, start timing when the thermometer on the four-necked flask reaches 110°C, vacuum pressure ≤ -0.08MPa, keep the temperature at 110°C ~ 120°C, and vacuum dehydration for 3 hours under the condition of pressure ≤ -0.08MPa .

[0061] (2) When the water content in the polyol is less than 0.05%, turn off the vacuum pump, reduce the temperature of the oil bath, and when the temperature of the thermometer drops to 75°C, slowly add 42.6g of isophorone diisocyanate and 32.2g of six After the addition of methylene diisocyanate, stir evenly, start to heat up, when the temperature reaches 90°C, start timing, and react at constant temperature for 1h. The -NCO content in the m...

Embodiment 3

[0066] (1) First, 150g polytetrahydrofuran ether glycol (PTMG2000), 100g polypropylene glycol (PPG3000) and 50g polypropylene glycol (PPG4000) were added to a 1000ml four-necked flask with electric stirring, thermometer, constant pressure funnel and vacuum pump, and then opened Electric stirrer, oil bath, vacuum pump, start timing when the thermometer on the four-necked flask reaches 110°C, vacuum pressure ≤ -0.08MPa, keep the temperature at 110°C ~ 120°C, and vacuum dehydration for 3 hours under the condition of pressure ≤ -0.08MPa .

[0067](2) When the water content in the polyol is less than 0.05%, turn off the vacuum pump and lower the temperature of the oil bath. When the temperature of the thermometer drops to 75°C, slowly add 72.22g of isophorone diisocyanate through the constant pressure funnel. Stir evenly, start to heat up, when the temperature reaches 90°C, start timing, and react at constant temperature for 1 hour. The -NCO content in the mixture was determined t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| color fastness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com