Radioactive surface strippable detergent and preparation method thereof

A radioactive and decontaminant technology, used in radioactive purification, coating, nuclear engineering, etc., can solve the problems of not carrying out real hot chamber decontamination experiments, staying in additives, etc., to achieve good peelability, long shelf life, and stability. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

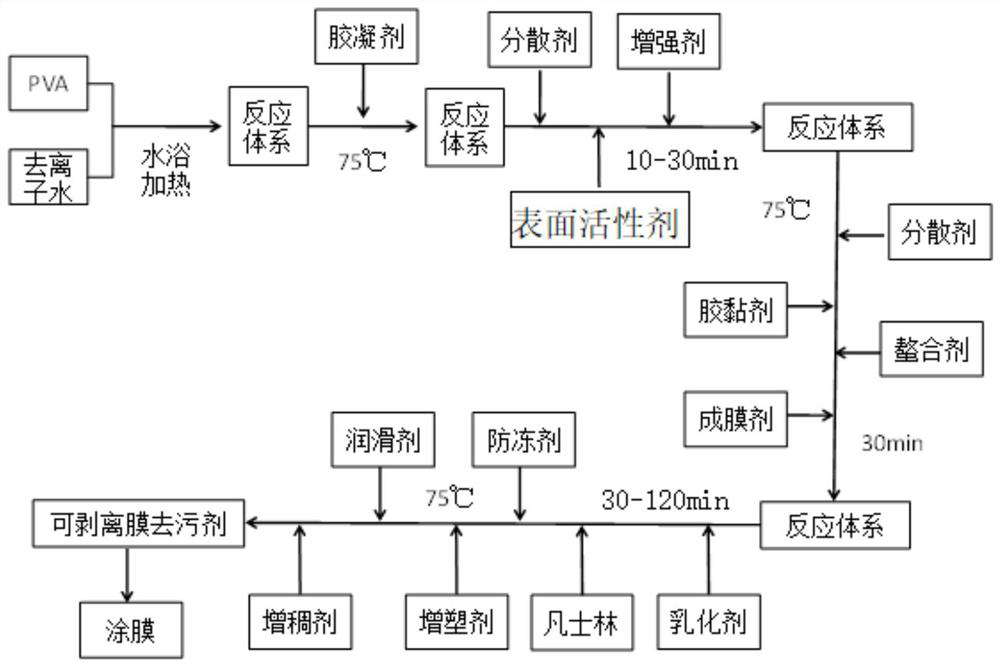

[0071] The preparation method of radioactive surface strippable detergent, comprises the following steps:

[0072] a. Dissolve polyvinyl alcohol in water, stir at 90-100°C for 24-48 hours, wait until the polyvinyl alcohol is completely dissolved, then add gelling agent until completely dissolved, and cool down to 70-80°C, then add dispersant and reinforcing agent React with a surfactant for 10-30 minutes to obtain solution A;

[0073] b. Add dispersant, adhesive, chelating agent, and auxiliary film-forming agent into solution A, and wait for complete dissolution to obtain solution B;

[0074] c. Add lubricant, antifreeze, plasticizer, petrolatum, emulsifier and thickener to solution B, mix well, react for 30min to 120min, and then cool to obtain detergent;

[0075] Wherein, the temperature of the reaction system in step b and step c is 70-80°C.

[0076] The preparation of the detergent of the present invention needs to be carried out according to the mixing method of the pre...

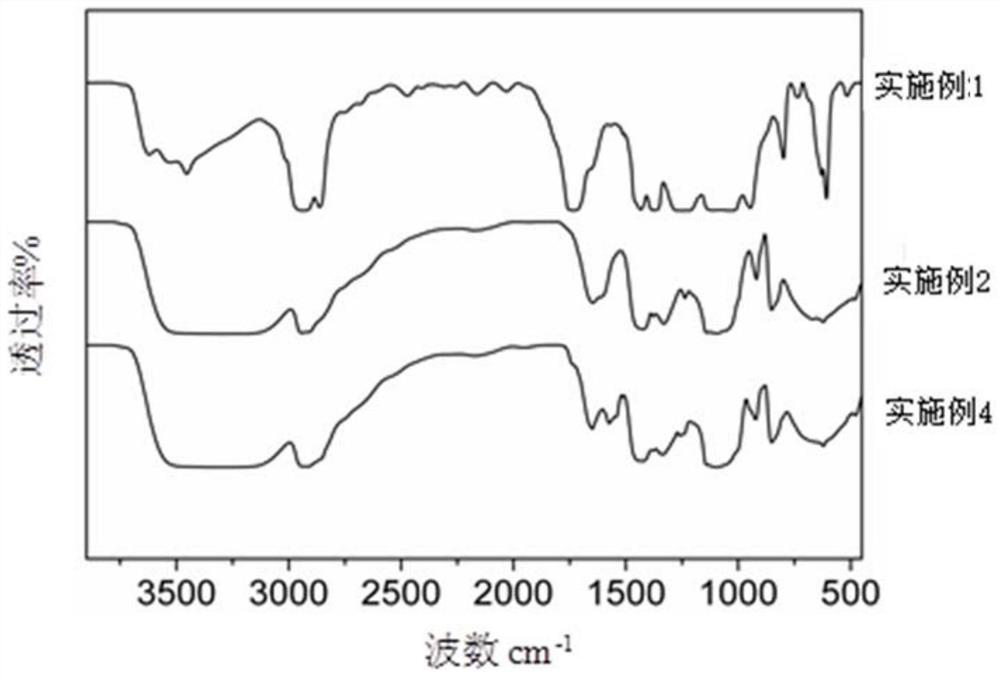

Embodiment 1

[0085] (1) Put 15g of PVA in 200mL of water, heat to 98°C, stir for 24h to dissolve completely; then lower the temperature to 90°C, and keep stirring for 30min. Then add 0.5g agar, and lower the temperature to 75°C, and react for 10min. Then add 0.3g of talcum powder, 0.5g of white carbon black, and 0.3g of sodium stearate, stir at 75°C, and react for 10min to obtain solution A.

[0086](2) Dissolve 0.10g of sodium tripolyphosphate, 0.50g of starch, 0.1g of citric acid, and 0.2g of acrylic resin in water, disperse evenly, then add them to solution A, and keep stirring at 75°C to obtain a solution b.

[0087] (3) 2g Span 60, 0.6g diethylene glycol, 1.0g dimethyl phthalate, 0.15g petrolatum and 0.5g sodium alkylbenzene sulfonate (dissolve 0.5g sodium alkylbenzene sulfonate in solution in deionized water) was added to solution B, stirred and mixed evenly, and reacted for 30 minutes. Natural cooling is adopted to obtain a detergent.

[0088] The obtained detergent was observed...

Embodiment 2

[0090] (1) Preparation of oxidized starch: Stir and mix starch and water at a mass ratio of 1:10, adjust the pH value of the system to about 10 with NaOH with a concentration of 4%; then add CuSO 4 (0.1mol / L, 0.6mL) solution was used as a catalyst, stirred evenly, and then added H 2 o 2 (mass fraction 0.6%) solution oxidizes the starch, the oxidation time is 20min, the oxidation temperature is 30°C, and the unreacted H is removed with sodium bisulfite after oxidation. 2 o 2 . The prepared oxidized starch is used as an adhesive for later use.

[0091] (2) Put 15g of PVA in 200mL of water, heat to 98°C, stir for 24h to dissolve completely; then lower the temperature to 90°C, and keep stirring for 30min. Then add 0.5g agar, and lower the temperature to 75°C, and react for 10min. Add 0.3g of talcum powder, 0.5g of white carbon black, and 0.3g of sodium stearate, stir at 75°C, and react for 10min to obtain solution A.

[0092] (3) Dissolve 0.10g sodium tripolyphosphate, 0.50g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com