Method for two-stage leaching of nickel and cobalt from crude nickel and cobalt hydroxide

A nickel-cobalt hydroxide, two-stage leaching technology, which is applied in the direction of improving process efficiency, can solve the problems of extraction and impurity removal pressure, and achieve the effect of reducing leaching costs, reducing sulfuric acid consumption and water consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

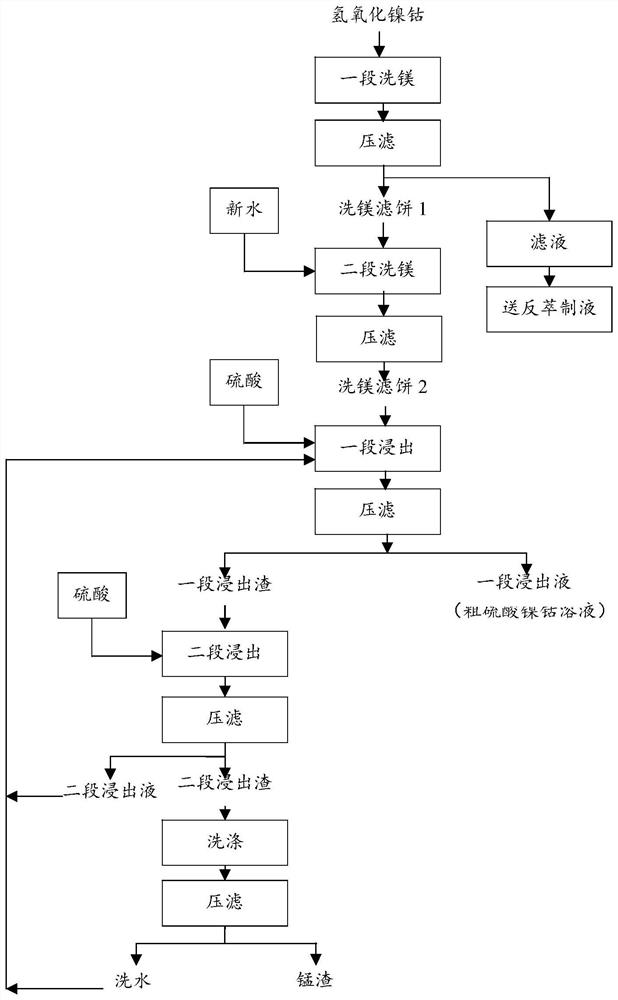

Method used

Image

Examples

Embodiment 1

[0026] A Circular magnesium washing: according to the liquid-solid ratio of 3.5 to 1, cyclic magnesium washing, add 1 / 3 of the second-stage magnesium washing liquid into the first-stage magnesium washing, and leaching at room temperature for 0.5h, at this time, the washing rate of magnesium element is 60.5% .

[0027] Stage B leaching: After washing, the filter cake is slurried at a liquid-solid ratio of 3.8 to 1. When the leaching temperature is 70°C, sulfuric acid is added to adjust the pH value of the solution to keep it at about 2.0. After leaching for 1.5 hours, the acid-mineral ratio at this time is 0.68 , after the end, the leaching slurry is press-filtered and solid-liquid separated to obtain a section of leachate and a section of leaching slag. The leaching rates of nickel and cobalt elements in this section are 97.8% and 83.3% respectively, and the leaching rate of the first section of slag is 10%.

[0028] C Second-stage leaching: Use the first-stage leaching slag a...

Embodiment 2

[0031] A Circular washing of magnesium: Circular washing of magnesium according to the liquid-solid ratio of 3.5 to 1, adding 1 / 3 of the washing solution of the second-stage magnesium washing to the first-stage magnesium washing, and leaching at room temperature for 1 hour. At this time, the washing rate of magnesium element is 61%.

[0032] Stage B leaching: After washing, the filter cake is slurried at a liquid-solid ratio of 4 to 1. When the leaching temperature is 75°C, sulfuric acid is added to adjust the pH value of the solution to keep it at about 1.5. After leaching for 2 hours, the acid-mineral ratio at this time is 0.7. After the completion, press filter the leaching slurry and separate solid and liquid to obtain a first stage of leachate and a stage of leaching slag. The leaching rates of nickel and cobalt elements in this stage are 98.2% and 85.5% respectively, and the leaching rate of the first stage of slag is 10%.

[0033] C Second-stage leaching: Use the first-s...

Embodiment 3

[0036] A Circular washing of magnesium: according to the liquid-solid ratio of 4 to 1, cyclic washing of magnesium, adding 1 / 3 of the second-stage magnesium washing solution to the first-stage magnesium washing, leaching at room temperature for 1 hour, and the washing rate of magnesium element is 62%.

[0037] Stage B leaching: After washing, the filter cake is slurried at a liquid-solid ratio of 4 to 1. When the leaching temperature is 75°C, add sulfuric acid to adjust the pH value of the solution to keep it at about 2.5. After leaching for 1.5 hours, the acid-mineral ratio at this time is 0.69 , after the end, the leaching slurry is press-filtered and solid-liquid separated to obtain a section of leachate and a section of leaching slag. The leaching rates of nickel and cobalt elements in this section are 97% and 83% respectively, and the leaching rate of the first section of slag is 10%.

[0038] C Second-stage leaching: Use the first-stage leaching slag as the raw material f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com