Preparation process of high-power unipolar pulse magnetron sputtering CrSiCN film

A preparation process, unipolar pulse technology, applied in sputtering plating, metal material coating process, ion implantation plating and other directions, to achieve the effect of dense coating, excellent wear resistance and corrosion resistance, and good bonding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

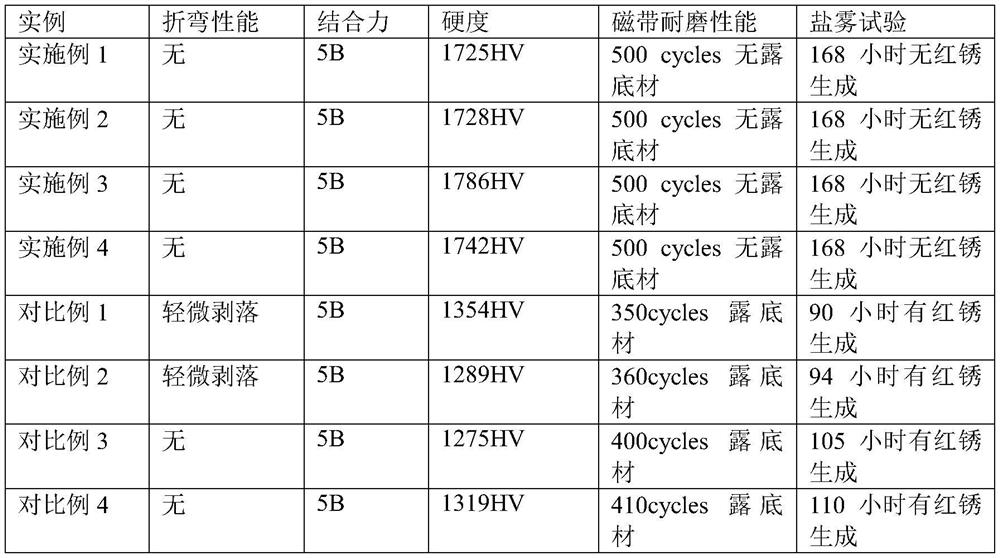

Examples

Embodiment 1

[0046] Embodiment 1 A kind of preparation technology of high-power unipolar pulse magnetron sputtering CrSiCN film comprises the following steps:

[0047] 1. Preparation:

[0048] 3 Cr flat targets, 1 Si flat target and 4 Cr arc targets are installed on the vacuum coating machine; the workpiece is degreased by ultrasonic wave and cleaned with pure water, and the cleaned workpiece is dried and fixed on the turntable in the coating chamber , evacuate the coating chamber and turn on the turret to rotate, then turn on the heater to preheat the workpiece at a speed of 480r / min;

[0049] 2. Glow cleaning:

[0050] Vacuum the coating chamber to 2×10 -2 Pa, and raise the temperature to 180°C for glow cleaning, then pass argon gas with a flow rate of 400 sccm, turn on the bias power supply to 550V for 25 minutes, and continue vacuuming to 6×10 -3 Pa, and then the coating deposition process

[0051] 3. Coating precipitation:

[0052] (31) Deposition of the base ion plating film (Cr...

Embodiment 2

[0058] Embodiment 2 A preparation process of high-power unipolar pulse magnetron sputtering CrSiCN film, comprising the following steps:

[0059] 1. Preparation:

[0060] 3 Cr flat targets, 1 Si flat target and 4 Cr arc targets are installed on the vacuum coating machine; the workpiece is degreased by ultrasonic wave and cleaned with pure water, and the cleaned workpiece is dried and fixed on the turntable in the coating chamber , evacuate the coating chamber and turn on the turret to rotate, then turn on the heater to preheat the workpiece at a speed of 720r / min;

[0061] 2. Glow cleaning:

[0062] Vacuum the coating chamber to 4×10 -2 Pa, and raise the temperature to 220°C for glow cleaning, then pass argon gas with a flow rate of 600 sccm, turn on the bias power supply to 650V for 35 minutes, and continue to vacuumize to 8×10 -3 Pa, and then the coating deposition process

[0063] 3. Coating precipitation:

[0064] (31) Deposition of the base ion plating film (Cr): fee...

Embodiment 3

[0069] Embodiment 3 A preparation process of high-power unipolar pulse magnetron sputtering CrSiCN film, comprising the following steps:

[0070] 1. Preparation:

[0071] 3 Cr flat targets, 1 Si flat target and 4 Cr arc targets are installed on the vacuum coating machine; the workpiece is degreased by ultrasonic wave and cleaned with pure water, and the cleaned workpiece is dried and fixed on the turntable in the coating chamber , evacuate the coating chamber and turn on the turret to rotate, then turn on the heater to preheat the workpiece at a speed of 500r / min;

[0072] 2. Glow cleaning:

[0073] Vacuum the coating chamber to 3×10 -2 Pa, and raise the temperature to 200°C, perform glow cleaning, then pass argon gas, the flow rate is 500sccm, turn on the bias power supply to 600V for 30 minutes, and continue to vacuumize to 7×10 -3 Pa, and then the coating deposition process

[0074] 3. Coating precipitation:

[0075] (31) Deposition of the base ion plating film (Cr): a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com