Stepping type high-precision photoetching machine

A high-precision, lithography technology, applied in the field of lithography, can solve the problems of temperature change, image etching prone to errors, etching accuracy prone to errors, etc., to achieve the effect of ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In this technical solution:

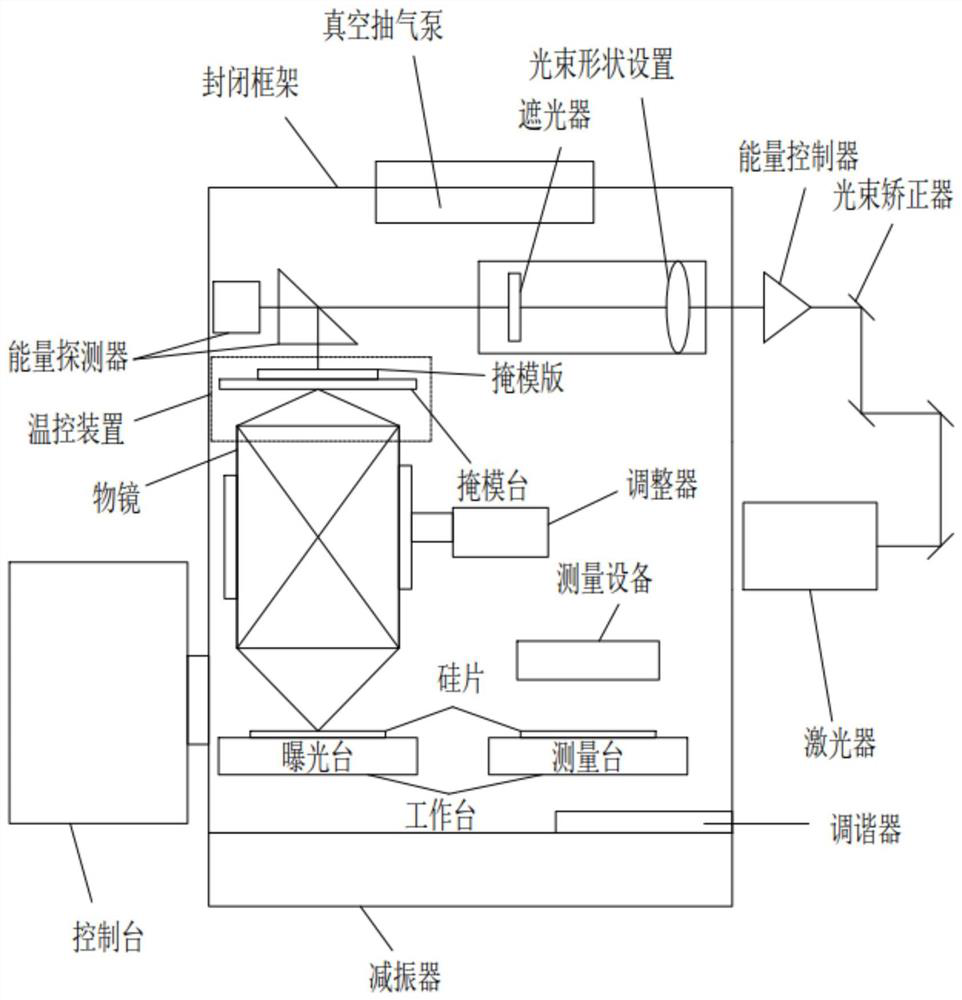

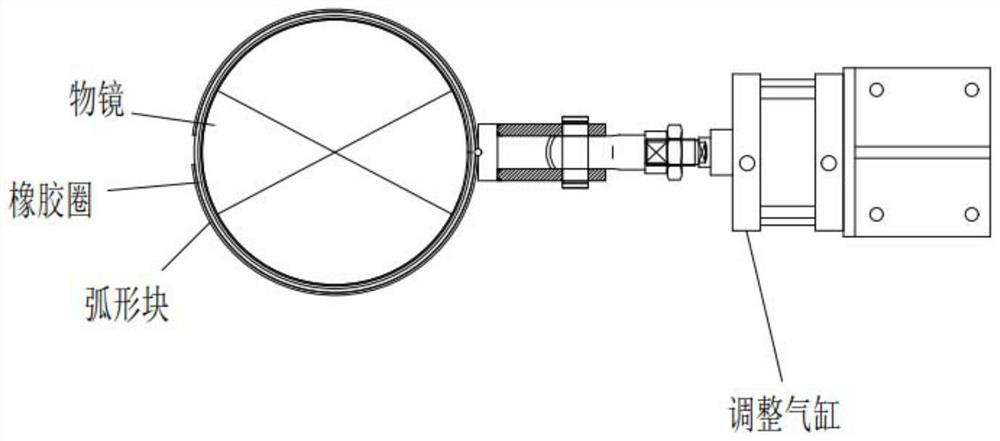

[0025] see figure 1 , figure 2 , the present invention provides a step-by-step high-precision photolithography machine, including a workbench, a laser, a beam straightener, an energy controller, an energy detector, a beam shape control, a shutter, a reticle, a mask table, an objective lens, Wafers, Enclosed Frames, Vibration Absorbers, Temperature Controls, Regulators, and Consoles; Stages, Energy Controllers, Beam Shape Control, Shutters, Energy Detectors, Energy Controllers, Reticles, Mask Stages, Objectives , silicon chip, temperature control device, and adjuster are set inside the closed frame; lasers, beam correctors, energy controllers, and consoles are set outside the closed frame; the bottom of the closed frame is equipped with a shock absorber; energy controller, beam shape control , light shield, energy detector, and energy controller are located on the same horizontal line, and are arranged in sequence from left to right; the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com