Preparation method of neodymium-doped tin dioxide photocatalytic material

A technology of photocatalytic materials and tin dioxide, applied in the field of photocatalytic materials, can solve the problems of low catalytic efficiency and achieve the effects of improving catalytic efficiency, promoting photocatalytic reaction, and good photocatalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] The preparation method of neodymium-doped tin dioxide photocatalytic material of the present invention specifically includes the following steps:

[0022] Step 1. Mix the stannous chloride, citric acid and CTAB and add them to deionized water. After stirring, a mixed solution is obtained. Add hydrated neodymium nitrate to the mixed solution, and stir for 0.5h-1h to obtain a mixed solution; stannous chloride, The molar ratio of citric acid, CTAB and hydrated neodymium nitrate is 2:3:4:0.015-2:3:4:0.035.

[0023] SnO 2 It can be obtained by hydrolysis of tin salt solution, the specific reaction is as follows:

[0024] S n 2+ +2H 2 O→S n (OH) 2 +2H +

[0025]

[0026]

[0027] S n (OH) 4 +2OH-→S n (OH) 6 2-

[0028] S n (OH) 6 2- →S n O 2 +2OH - +2H 2 O

[0029] Among them, citric acid and CTAB can play a role in morphology control. Cationic surfactant CTAB in SnO 2 The formation of the structure plays a vital role. On the one hand, the presence of CTAB can reduce the surface tens...

Embodiment 1

[0034] Step 1. Mix 0.113g of stannous chloride, 0.631g of citric acid, and 0.4g of CTAB, then add deionized water, stir to obtain a mixed solution, add 0.0049g of hydrated neodymium nitrate to the mixed solution, and stir for 0.5h to obtain a mixed solution ;

[0035] Step 2. Place the mixed solution in a polytetrafluoroethylene reactor for hydrothermal reaction. The reaction temperature is 200°C and the reaction time is 24 hours. After cooling to room temperature, take out the bottom product of the reaction vessel and centrifuge it. Get a sample

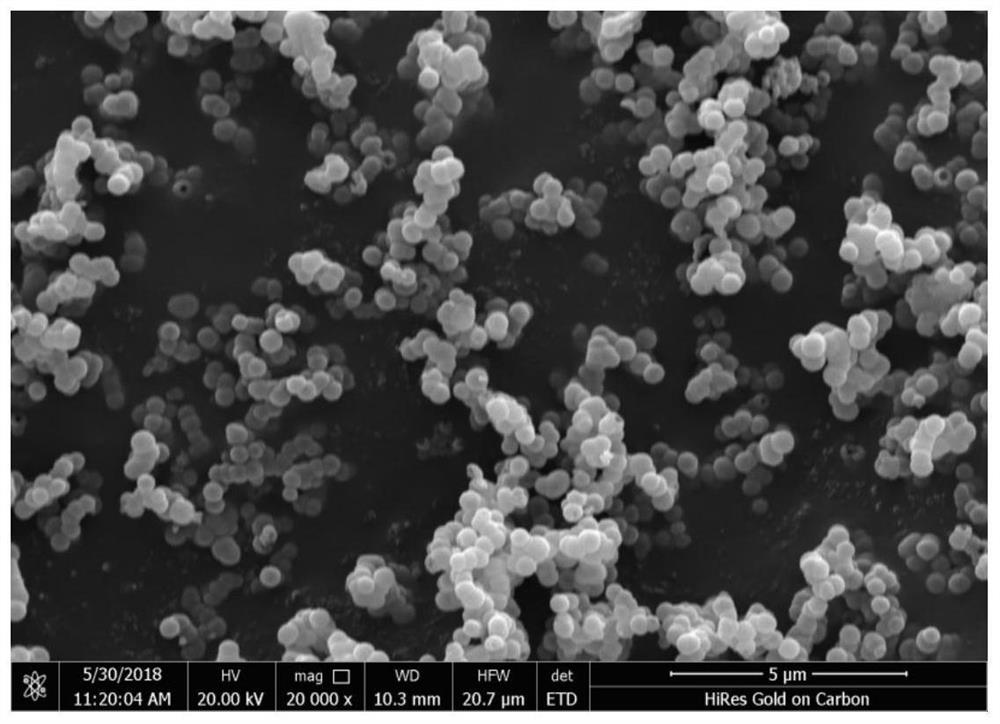

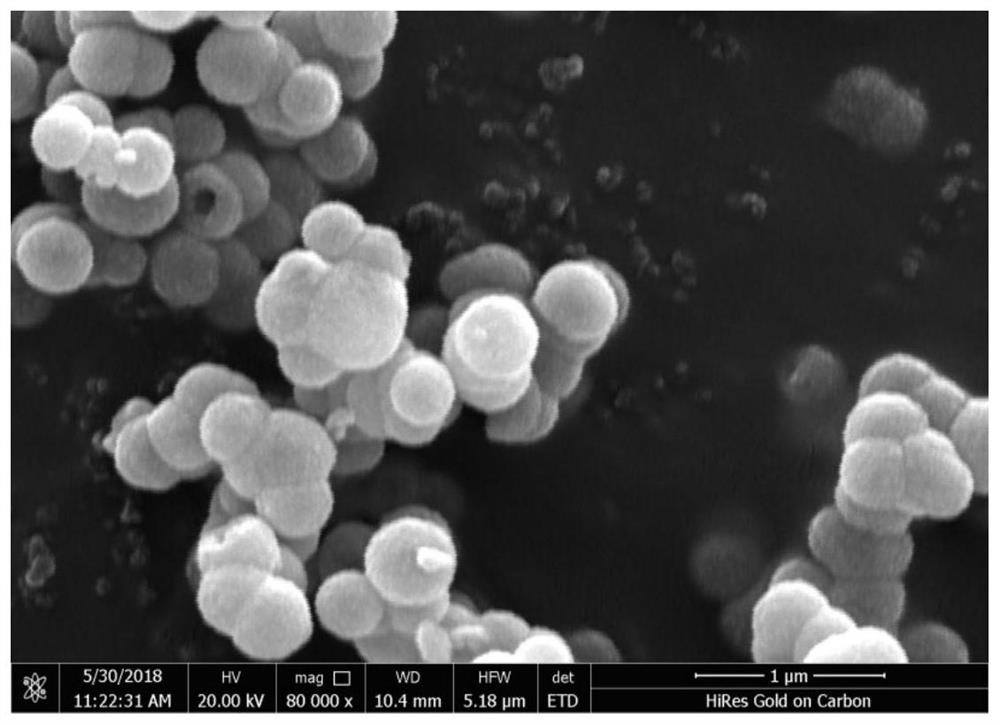

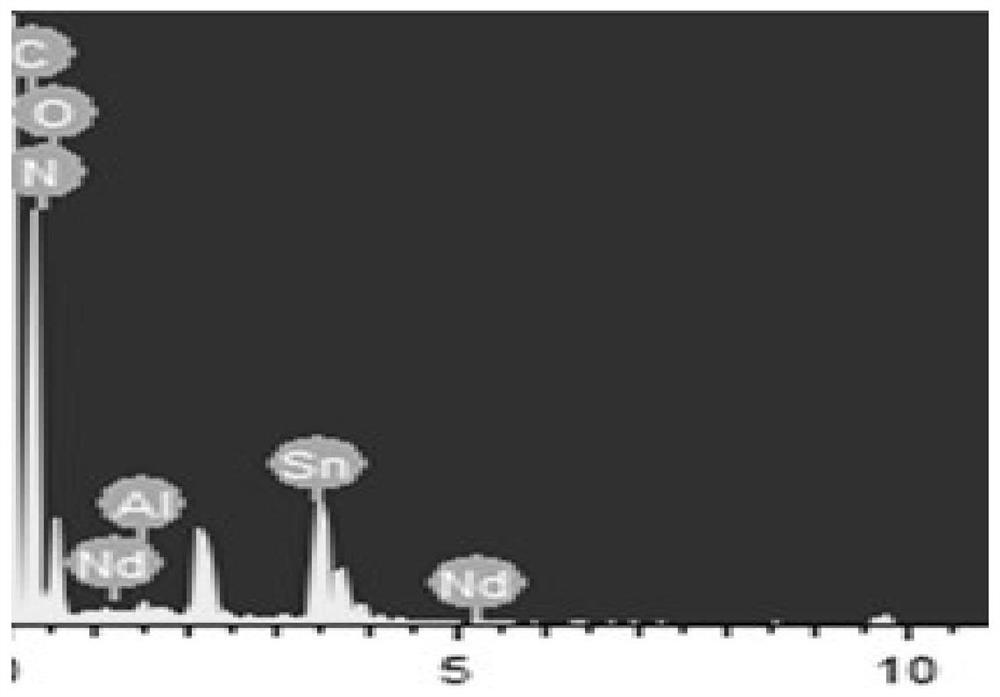

[0036] Step 3. Wash the sample with deionized water and ethanol in sequence to obtain the neodymium-doped tin dioxide photocatalytic material. See the SEM picture figure 1 , See the high magnification SEM image figure 2 , See the EDS diagram image 3 . by figure 1 figure 2 It can be seen that the prepared product is composed of a large amount of hollow spherical materials, and the SnO prepared in Example 1 2 The diameter of the spher...

Embodiment 2

[0038] Step 1. Mix 0.115g of stannous chloride, 0.638g of citric acid, and 0.5g of CTAB, then add deionized water, stir to obtain a mixed solution, add 0.0082g of hydrated neodymium nitrate to the mixed solution, and stir for 0.8h to obtain a mixed solution ;

[0039] Step 2. Place the mixed solution in a polytetrafluoroethylene reactor for a hydrothermal reaction. The reaction temperature is 180°C, and the reaction time is 20 hours. After cooling to room temperature, take out the bottom product of the reaction vessel and centrifuge it. Get a sample

[0040] Step 3. Wash the sample in the centrifuge tube with deionized water first, and repeat three times; then, wash the sample in the centrifuge tube with ethanol, and repeat three times to obtain the neodymium-doped tin dioxide photocatalytic material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com