A kind of self-supporting lithium-sulfur positive electrode material of network polymer containing N and O atoms and preparation method thereof

A positive electrode material and polymer technology, applied in the field of self-supporting lithium-sulfur positive electrode materials and their preparation, can solve the difficulties in meeting the commercialization requirements of lithium-sulfur batteries, the lack of polar sites, heteroatoms and pore structures in the capacity of multi-carbon materials Uncontrollable and other problems, to achieve the effect of inhibiting the shuttle effect, accelerating the redox reaction speed, and good conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] A method for preparing a self-supporting lithium-sulfur positive electrode material of a network polymer containing N and O atoms, comprising the following steps:

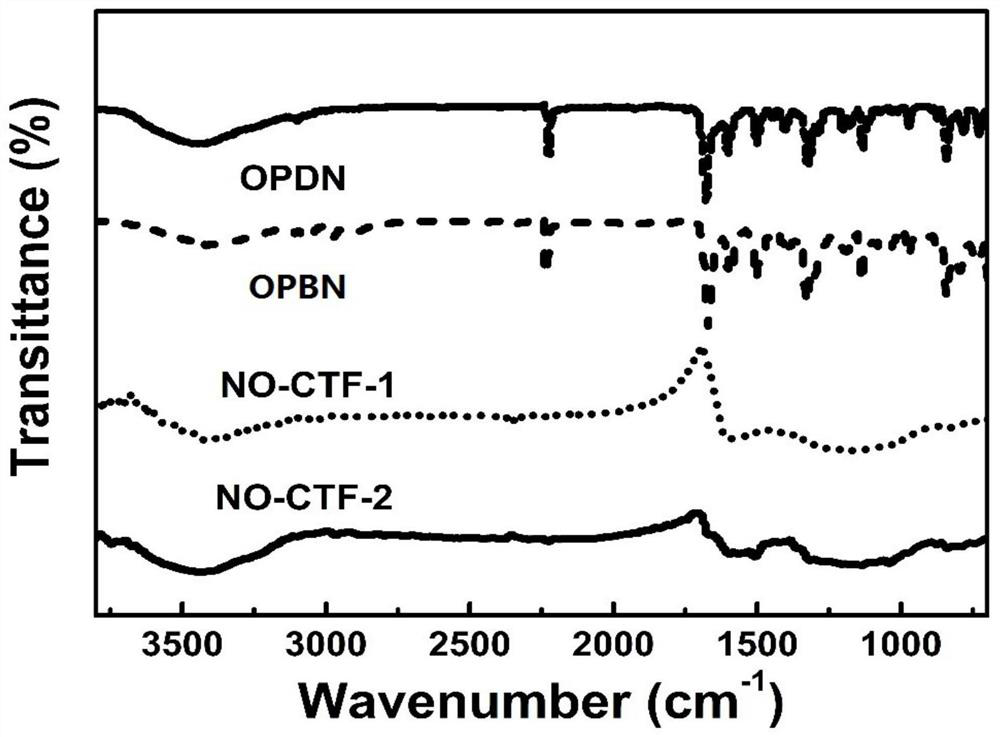

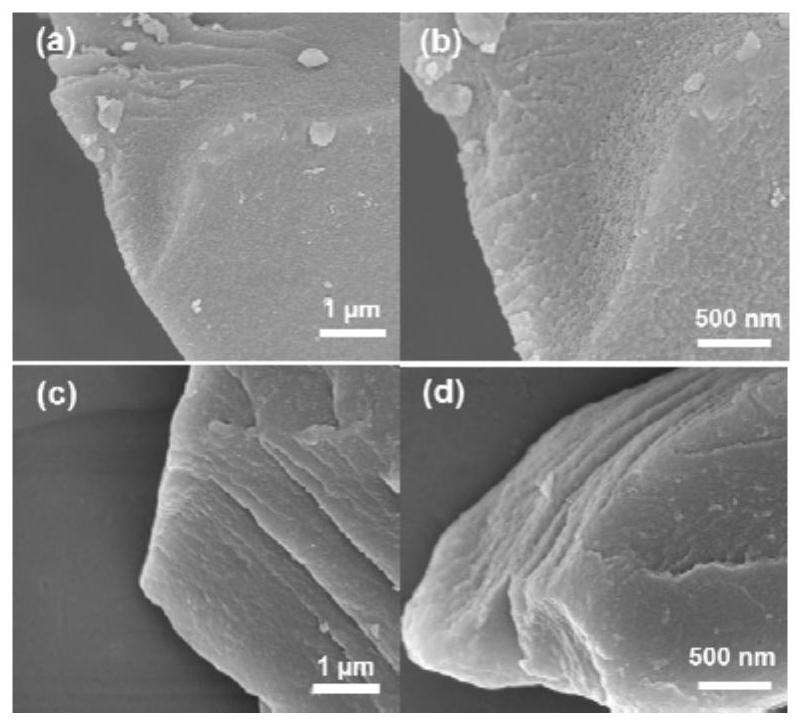

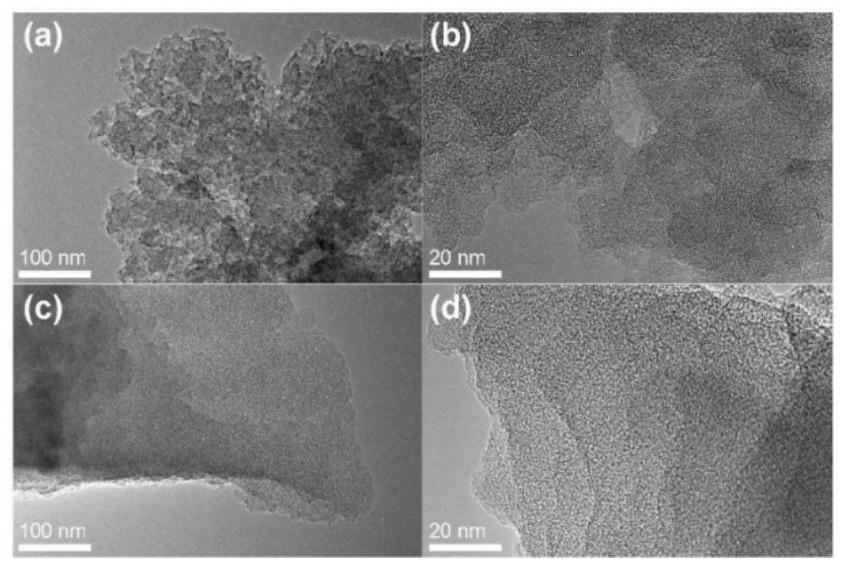

[0056] (1) Prepare dinitrile monomers containing N and O, and vacuum-dry the obtained dinitrile monomers at 100° C. for 24 hours; the dinitrile monomers are monomer 1 described in the Summary of the Invention, wherein Ar1 is benzene Ring, Ar Be benzene ring; Monomer 1 described in the present embodiment is OPDN, and wherein, the concrete preparation process of OPDN is as follows: in the there-necked flask, add the bromine (structural formula is as follows i shown), 3g potassium ferrocyanide, 3.5g sodium carbonate, 0.1g palladium acetate, add the N-methylpyrrolidone NMP of 100ml in the there-necked flask again, stir and under agitation vacuumize then fill with nitrogen, be warming up to React at 120°C for 12h; pour the obtained reaction solution into 500mL of ethanol, stand for 25h, filter with suction and co...

Embodiment 2

[0064] A method for preparing a self-supporting lithium-sulfur cathode material of a network polymer containing N and O atoms. Include the following steps:

[0065] (1) Prepare a dinitrile monomer containing N and O, and vacuum-dry the obtained dinitrile monomer at 100° C. for 24 hours; the dinitrile monomer is the monomer 1 described in the Summary of the Invention, wherein Ar1 is a Benzene, Ar3 is a benzene ring. (The dinitrile monomer described in this example is OPBN)

[0066] (2) with the prepared N, O dinitrile monomer and anhydrous zinc chloride prepared in step (1) in a molar ratio of 1:5, place in a quartz ampoule after mixing in a glove box, and vacuumize seal.

[0067] (3) The ampoule obtained in step (2) was placed in a muffle furnace for reaction: the temperature was raised to 400°C at a rate of 5°C / min, and the temperature was maintained for 10 hours; then the temperature was raised to 600°C at a rate of 1°C / min, and Incubate for 24h.

[0068] (4) Grind the ...

Embodiment 3

[0074] A method for preparing a self-supporting lithium-sulfur positive electrode material of a network polymer containing N and O atoms, comprising the following steps:

[0075] (1) Prepare dinitrile monomers containing N and O, and vacuum-dry the obtained dinitrile monomers at 100° C. for 24 hours; the dinitrile monomers are monomer 1 described in the Summary of the Invention, wherein Ar1 is benzene ring, and Ar3 is a benzene ring. For the specific preparation method, see step (1) of Example 1.

[0076] (2) with the prepared N, O dinitrile monomer of step (1) and anhydrous zinc chloride in a molar ratio of 1:5, in the glove box (water and oxygen content are less than 0.01ppm) after mixing Place in a quartz ampoule and vacuum seal.

[0077] (3) The ampoule obtained in step (2) was placed in a muffle furnace for reaction: the temperature was raised to 400°C at a rate of 5°C / min, and the temperature was maintained for 10 hours; then the temperature was raised to 800°C at a rat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com