Vulcanization-resistant, high-thermal-conductivity and high-temperature-resistant conductive gold adhesive

A high thermal conductivity, anti-vulcanization technology, applied in the direction of conductive adhesives, adhesives, epoxy resin glue, etc., to achieve high flexibility, meet high stability, and improve heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

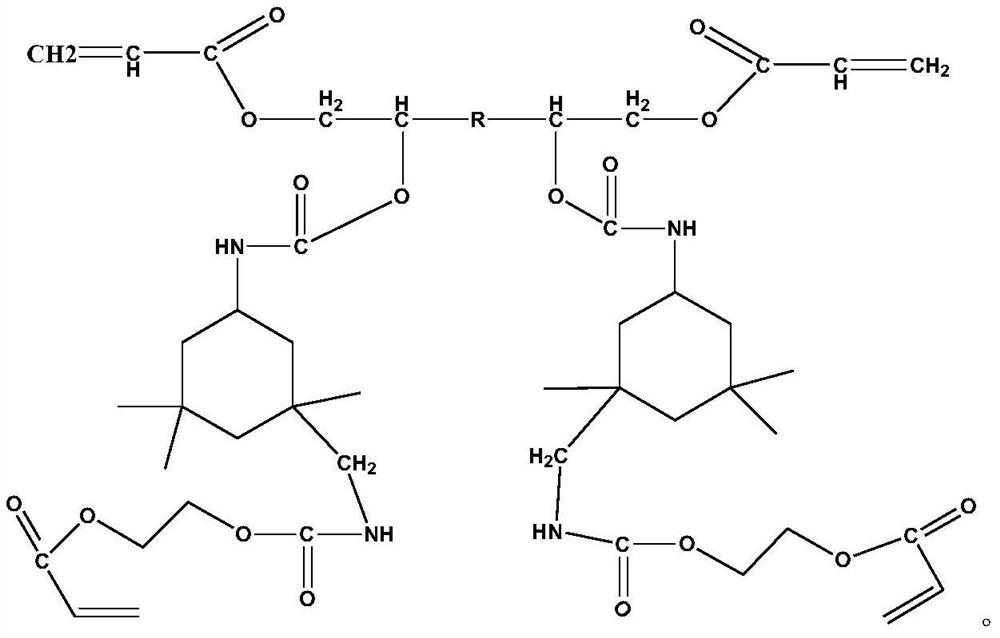

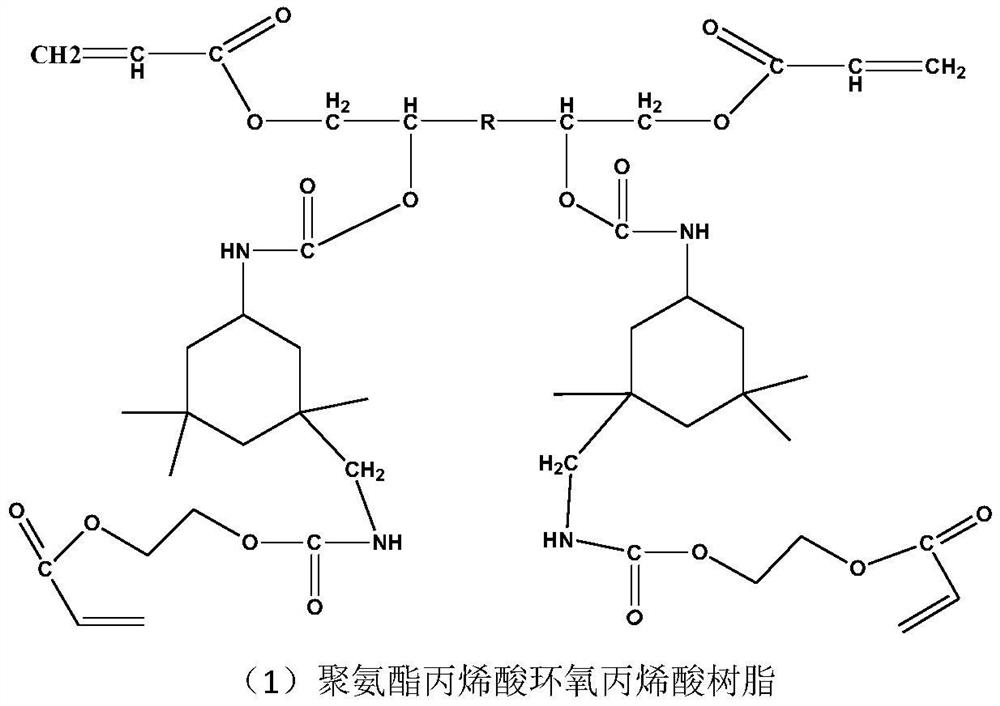

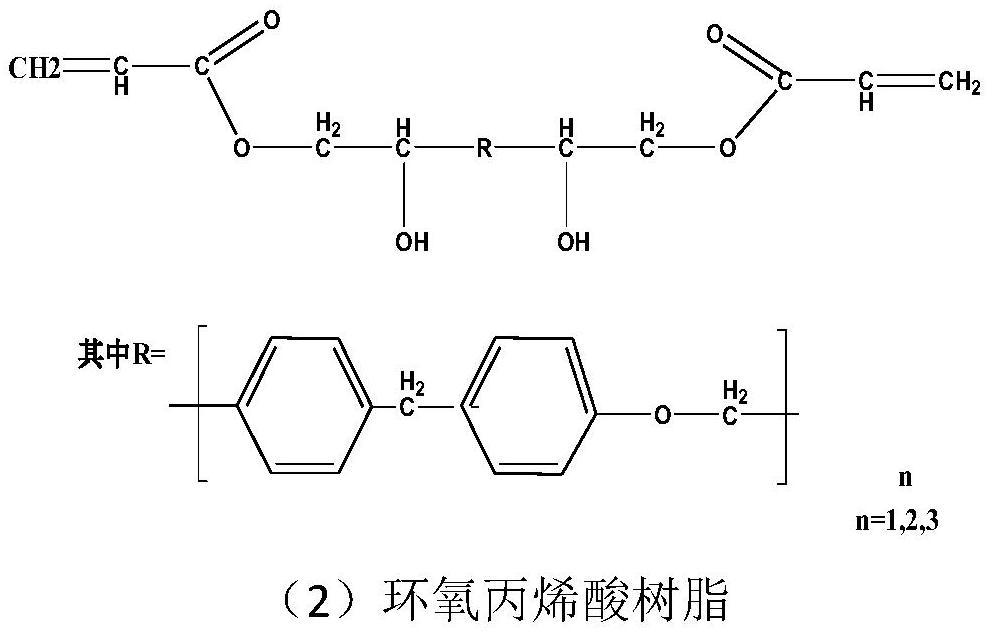

[0032] Preparation of polyurethane acrylic epoxy resin:

[0033] (1) Throw 60g IPDI, 0.2g antioxidant B225 into the four-necked flask, start stirring, heat up to 50 degrees, add 0.02g catalyst T-12, start to drop 115.6 bisphenol F type epoxy acrylic resin, drop for 0.5 hours After adding, keep warm for 2.5 hours, and control the temperature between 55-65 degrees;

[0034] (2) Sampling and measuring NCO, it was reduced to 4.48%;

[0035] (3) Then heat up to 75-85 degrees, add 0.2 g of polymerization inhibitor MEHQ, 0.02 g of catalyst T-12, add dropwise HEA, finish adding dropwise in 0.5 hours, keep warm for 2.5 hours, and control the temperature between 80-90 degrees;

[0036] (4) Take a sample to measure NCO, and if it falls below 0.1%, wash the resin three times with acetone and dry it in vacuum.

[0037] Preparation of modified flake gold powder:

[0038] (1) Chlorauric acid HAuCl 4 4H 2 O was dissolved in distilled water to prepare a 20% gold solution, and the solution...

Embodiment 1

[0044] 3 parts of polyurethane modified epoxy acrylate, 8 parts of epoxy resin 830LVP, 8 parts of epoxy acrylic thinner GMA, 0.5 parts of BMI, 3 parts of DDS, 0.2 parts of Trigonox 42S, 80 parts of modified flake gold powder, KH Add 0.3 parts of -570 coupling agent into the mixing kettle, stir to control the temperature at 20-40°C, stir at a speed of 300r / min, stir for 2h, and finally vacuumize for 0.5h, and discharge for inspection.

Embodiment 2

[0046] 5 parts of polyurethane modified epoxy acrylate, 6 parts of epoxy resin 830LVP, 8 parts of epoxy acrylic diluent GMA, 0.5 parts of PMI, 3 parts of DDS, 0.2 parts of Trigonox 42S, 80 parts of modified flake gold powder, KH- Add 0.3 parts of 570 coupling agent into the mixing tank, stir to control the temperature at 20-40°C, stir at a speed of 300r / min, stir for 2h, and finally vacuumize for 0.5h, and discharge for inspection.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com