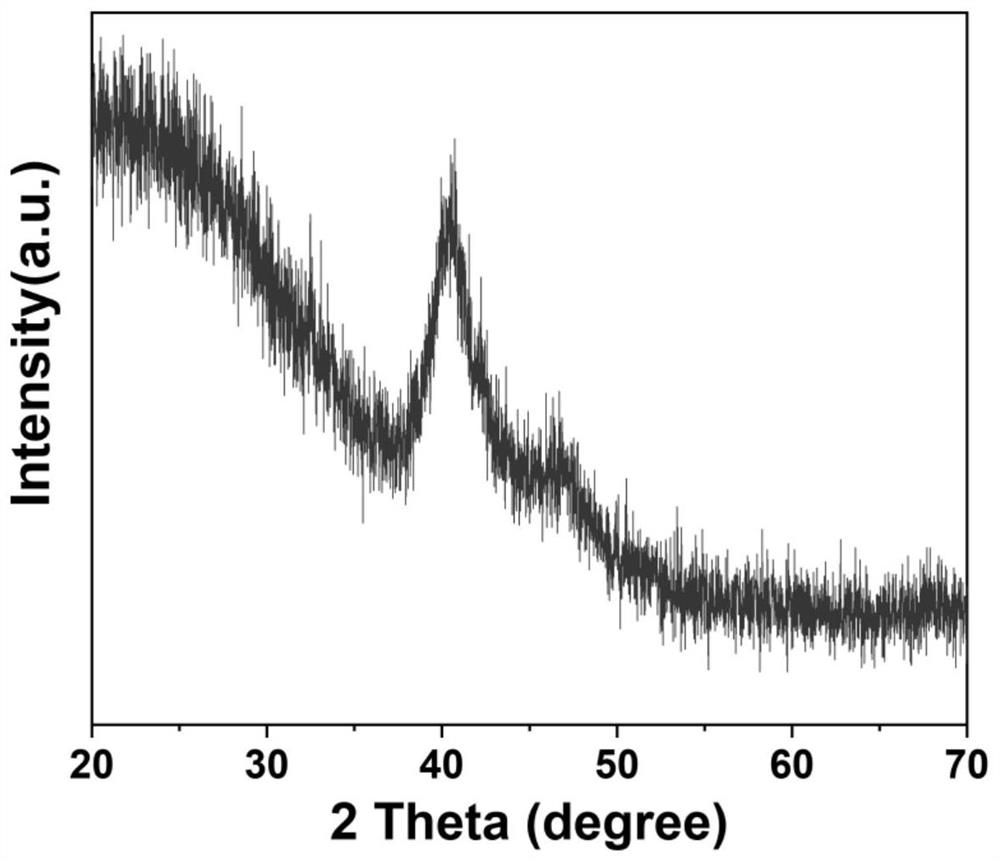

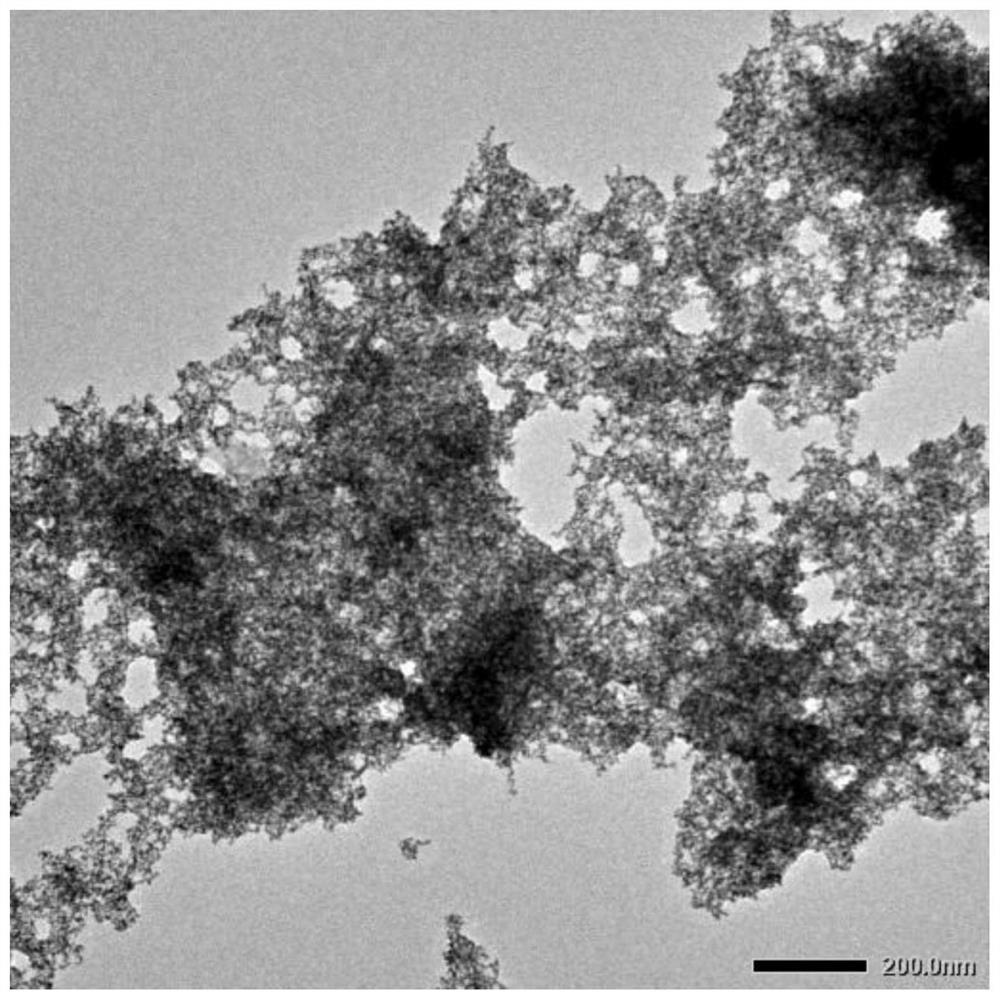

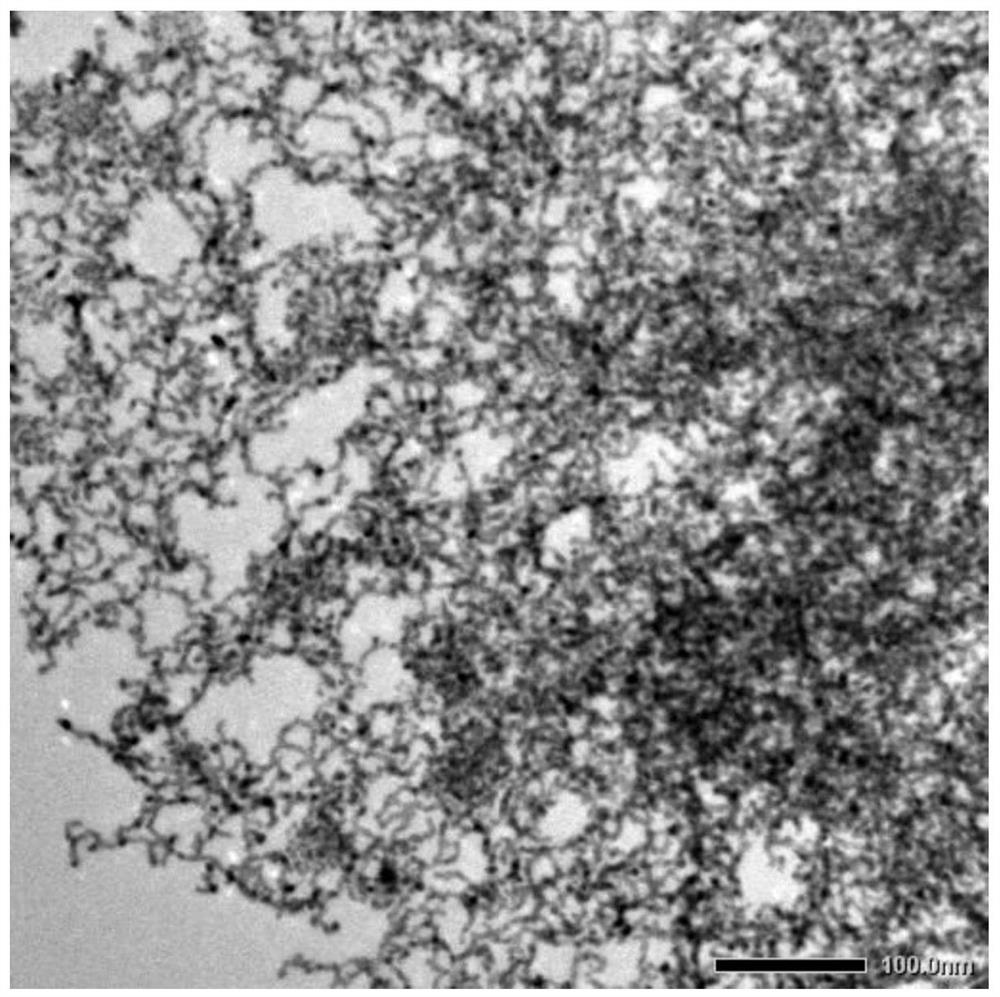

Copper-based catalyst with nanowire network structure, preparation method and application thereof

A technology of copper-based catalyst and network structure, which is applied in the direction of catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of waste of hydrogen source, incomplete nitrate reaction, etc., and achieve high nitrate The effect of reduction, high utilization rate of formic acid, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The preparation method specifically comprises the following steps:

[0032] First, mix polyvinylpyrrolidone and polyalcohol uniformly in a two-necked flask, wherein the ratio of the mass of polyvinylpyrrolidone to the volume of polyalcohol is 131 mg: (10-15) mL, and the polyalcohol is ethylene glycol and 1,3- Any of butanediol. One outlet of the two-necked flask is connected to the reflux pipe, open the circulating water, then heat the mixture in the two-necked flask to 200-220°C, and keep the temperature at reflux for 20-30 minutes; when refluxing, the other outlet of the two-necked flask is plugged with a rubber stopper. Secondly, add the aqueous solution of copper sulfate and palladium nitrate to the two-necked flask, continue to maintain magnetic stirring and reflux under the condition of 200-220 ℃ for 2-4 hours to carry out the reduction reaction, in the aqueous solution of copper sulfate and palladium nitrate, copper sulfate and The molar ratio of palladium nitra...

Embodiment 1

[0036] 1) First, mix 131mg of polyvinylpyrrolidone and 10mL of ethylene glycol in a two-necked flask uniformly. One outlet of the two-necked flask is connected to the reflux tube, open the circulating water, then heat the mixture in the two-necked flask to 220°C, and keep the temperature at reflux for 30 minutes; the other outlet of the two-necked flask is plugged with a rubber stopper during reflux. Next, add 4mL aqueous solution containing 0.1mmol copper sulfate and 0.1mmol palladium nitrate to the two-necked flask, continue to maintain magnetic stirring and reflux at a temperature of 220°C for 4h, then naturally cool the reaction flask to room temperature, and then pour the product in the flask Put it into a centrifuge tube, add 40mL acetone to the centrifuge tube, ultrasonically homogenize, put it in a centrifuge and centrifuge. Centrifuge washing again with a mixture of acetone and water to obtain a copper-based nanowire network structure, and finally disperse the catalys...

Embodiment 2

[0040] 1) First, mix 131mg of polyvinylpyrrolidone and 10mL of ethylene glycol in a two-necked flask uniformly. One outlet of the two-necked flask is connected to the reflux pipe, open the circulating water, then heat the mixture in the two-necked flask to 200°C, and keep the temperature at reflux for 30 minutes; the other outlet of the two-necked flask is plugged with a rubber stopper during reflux. Next, add 4mL aqueous solution containing 0.1mmol copper sulfate and 0.1mmol palladium nitrate to the two-necked flask, continue to maintain magnetic stirring and reflux at 200°C for 4h, then naturally cool the reaction flask to room temperature, and then pour the product in the flask Put it into a centrifuge tube, add 40mL acetone to the centrifuge tube, ultrasonically homogenize, put it in a centrifuge and centrifuge. Centrifuge washing again with a mixture of acetone and water to obtain a copper-based nanowire network structure, and finally disperse the catalyst in a certain vo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com