Cleaning equipment for refractory material production and using method thereof

A technology for cleaning equipment and refractory materials, which is applied in the directions of cleaning methods, cleaning methods and utensils, chemical instruments and methods using liquids, etc., which can solve the problems of increased cleaning costs, low cleaning efficiency, large dust impurities, etc., to save labor intensity. , waste reduction, multi-functional effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

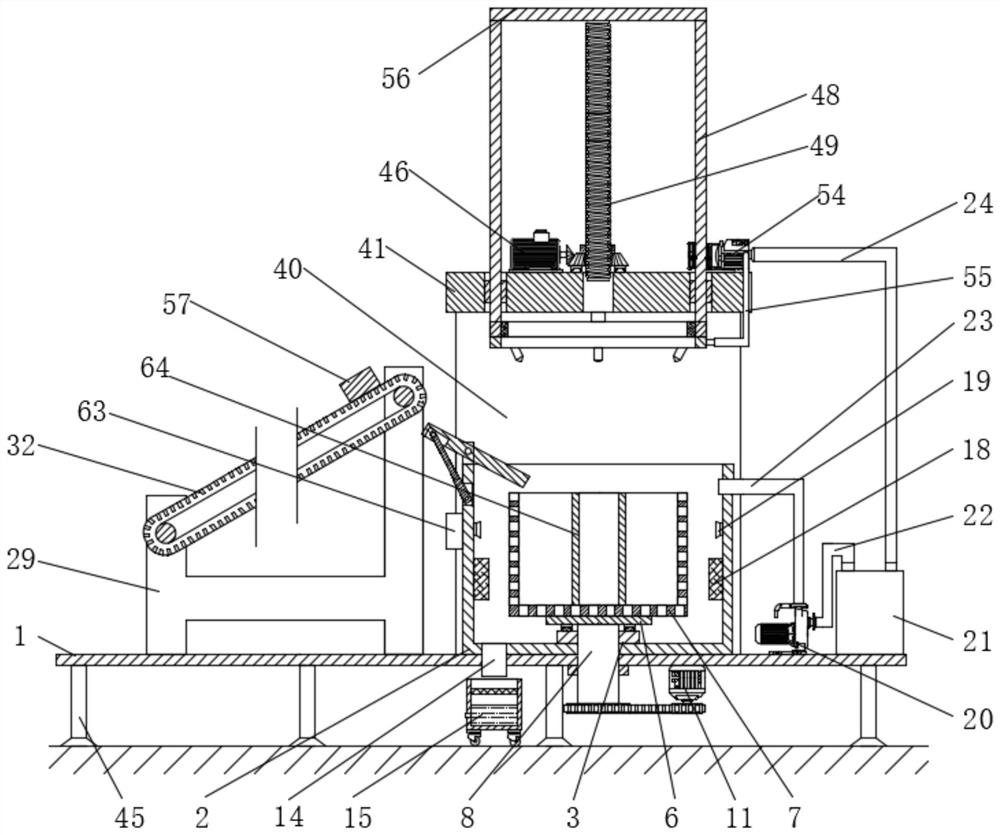

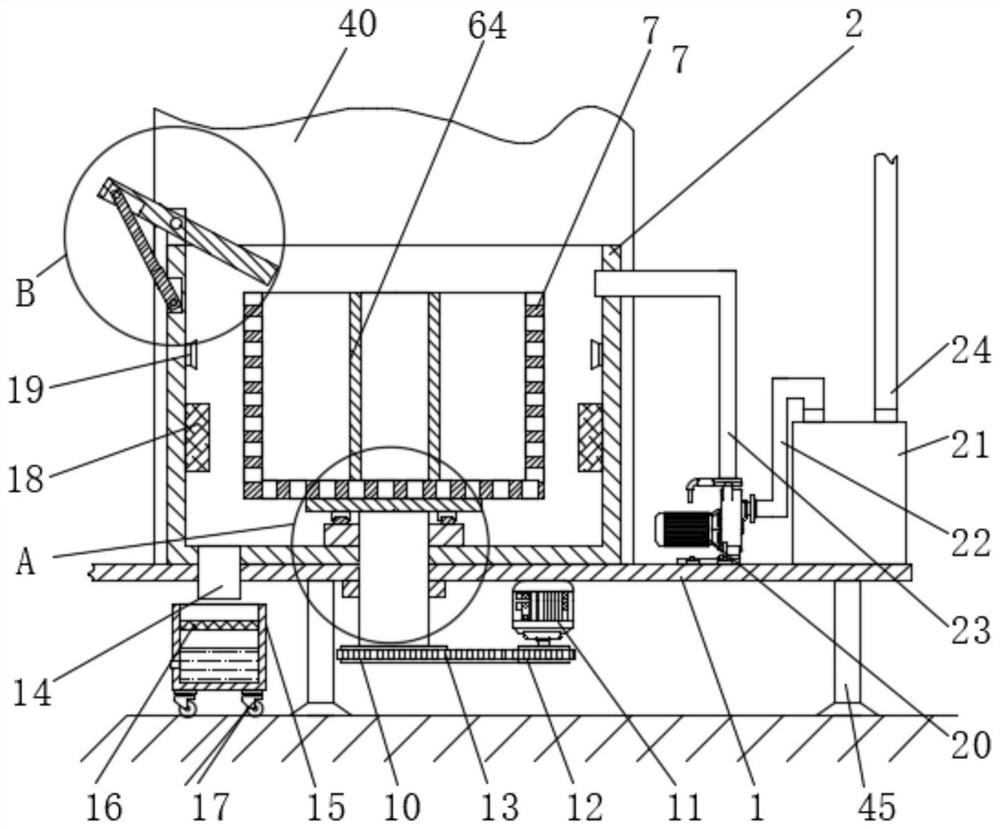

[0043] Embodiment one: if Figure 1-11 As shown, a cleaning device for refractory production includes a workbench 1, a cleaning bucket 2 is fixedly connected to the top of the workbench 1, a fixing plate 3 is fixedly connected to the inner wall of the bottom of the cleaning bucket 2, and the top of the fixing plate 3 slides Connected with a rotating plate 6, the top of the rotating plate 6 is fixedly connected with a hollow metal frame 7, the bottom inner wall of the hollow metal frame 7 is fixedly connected with a drum 64, and the bottom inner wall of the cleaning bucket 2 is rotatably connected with a rotating shaft 8. The top runs through the fixed plate 3 and is fixedly connected with the bottom of the rotating plate 6. The bottom end of the rotating shaft 8 runs through the workbench 1 and is fixedly connected with the first pulley 10. The bottom of the workbench 1 is fixedly connected with a rotating motor 11. The output shaft is fixedly connected with a second pulley 12...

Embodiment 2

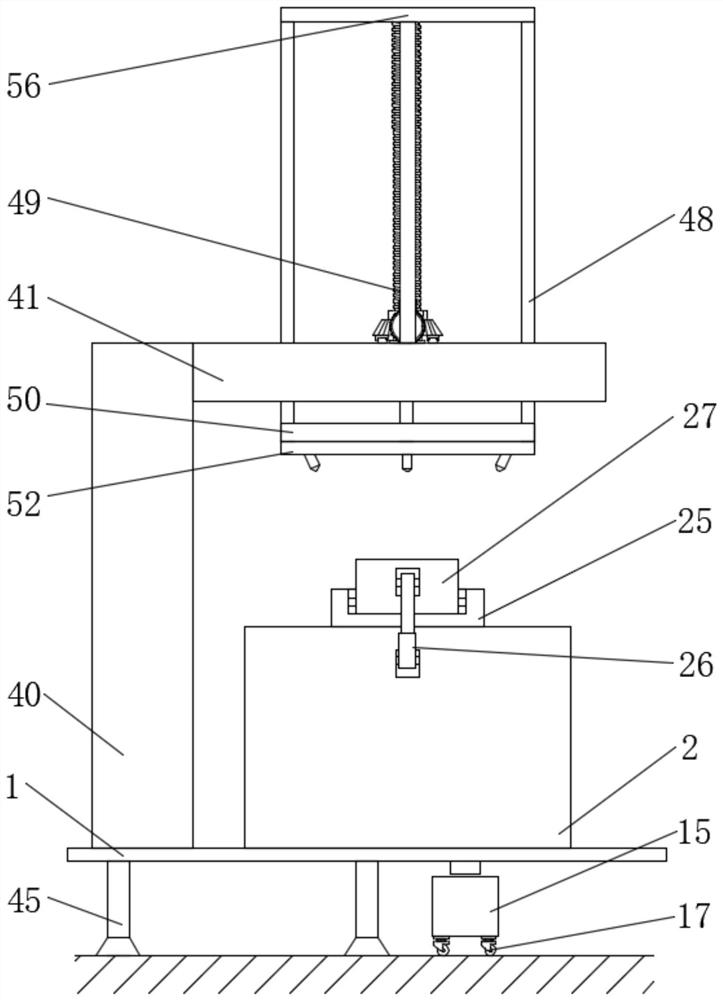

[0056] Embodiment two: if Figure 12-15 As shown, a cleaning device for refractory production, the difference between this embodiment and Embodiment 1 is that: the center of the bottom of the hollow metal frame 7 is fixedly connected with a cross plate 58, and the center of the top of the rotating plate 6 is provided with a cross Groove 59, the cross plate 58 is embedded in the cross groove 59, when cleaning is finished, the hollow metal frame 7 in the cleaning bucket 2 can be proposed from the rotating plate 6, and the raw material 57 is taken out, which is simple and convenient.

[0057] Working principle: Place the raw material 57 on the top of the conveyor belt 32, start the drive motor 37, the drive motor 37 drives the fourth synchronous wheel 38 to rotate, and the fourth synchronous wheel 38 drives the second synchronous belt 39 and the first synchronous belt 36 respectively. A synchronous wheel 33 and the second synchronous wheel 34 rotate, and then can drive the transm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com