Regeneration cleaning method for quartz part of semiconductor high-order process APC device

A semiconductor, high-end technology, applied in the field of cleaning, can solve the problems of corrosion of quartz body, long time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings.

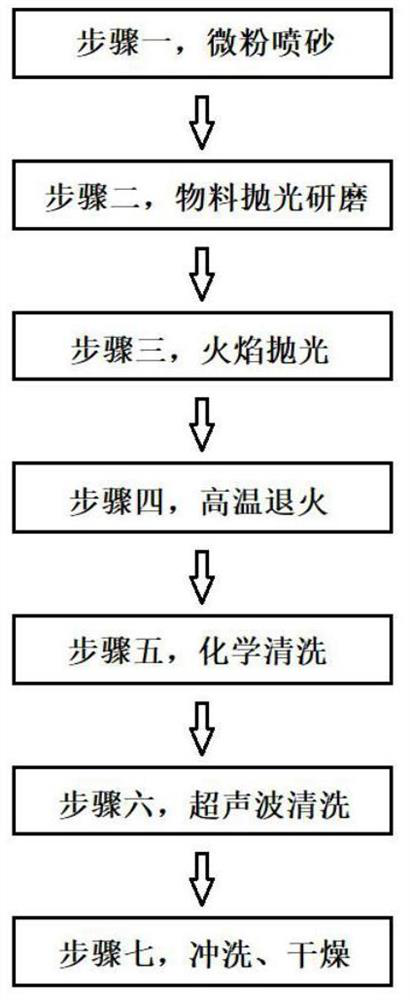

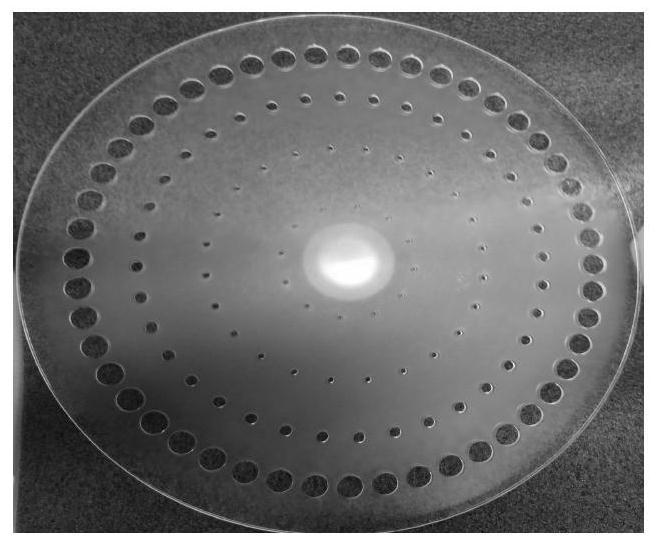

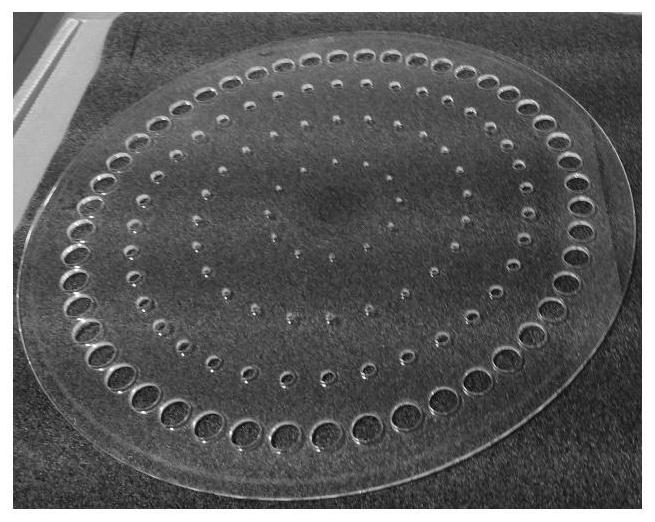

[0037] see Figure 1 to Figure 5 , the regeneration method of semiconductor APC equipment quartz part (gas distribution plate) in this embodiment, comprises the steps:

[0038] Step 1, micropowder blasting;

[0039] Use the gas protection jig for sand blasting, and perform WA400# micro-powder sand blasting on the quartz parts to remove the residue or deposits on the surface. The delivery gas pressure used is 0.5-1Kg.cm 2 , sandblasting time 3-5 minutes;

[0040] Step 2, physical grinding and polishing;

[0041] Use a rotating platform and a certain sieved silicon carbide abrasive to grind a specific area. Through multiple grindings of a variety of sieved silicon carbide abrasives (coarse first and then fine), the surface roughness of the quartz part is lower than 1.0um, and the turntable Speed 30-75rmp;

[0042] Step three, flame polishing;

[0043] Oxygen-hydr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com