Multi-layer copper-based zeolite fiber medical material, medical protective article and manufacturing method thereof

A copper-based zeolite, multi-layer technology, applied in the field of anti-epidemic sanitary appliances, can solve the problems of destroying cell structure, inability to achieve antibacterial and antiviral properties, and poor antiviral and antibacterial effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0088] The present invention is a method of preparing mask 1, comprising the steps of:

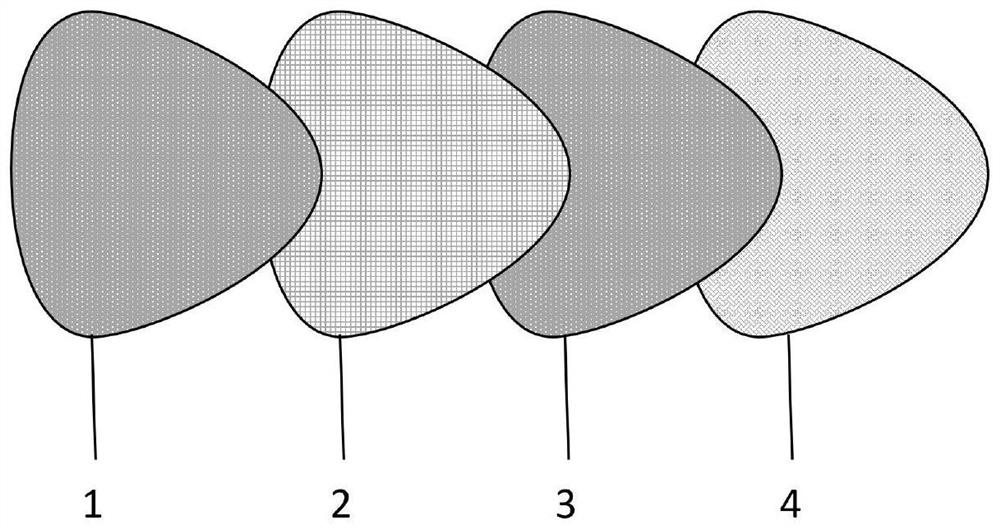

[0089] Mask comprising an outermost layer, a first intermediate layer, a second intermediate layer and the innermost layer; the outermost layer and a second intermediate layer made of copper-based fiber layer composed of zeolite; a first intermediate layer is a hydrophobic fibrous layer; innermost layer hydrophilic fiber layer.

[0090] Wherein the first intermediate layer of a low density and a hydrophobic or water-resistant and strong fibers, can be used typically contain low polyethylene terephthalate fibers and polyethylene and for the pressing of the processed point-bonded point-bonded nonwoven fabric layer density; porosity of the first intermediate layer is set at 40 ~ 60μm;

[0091] The innermost layer of the water-absorbent nonwoven fabric;

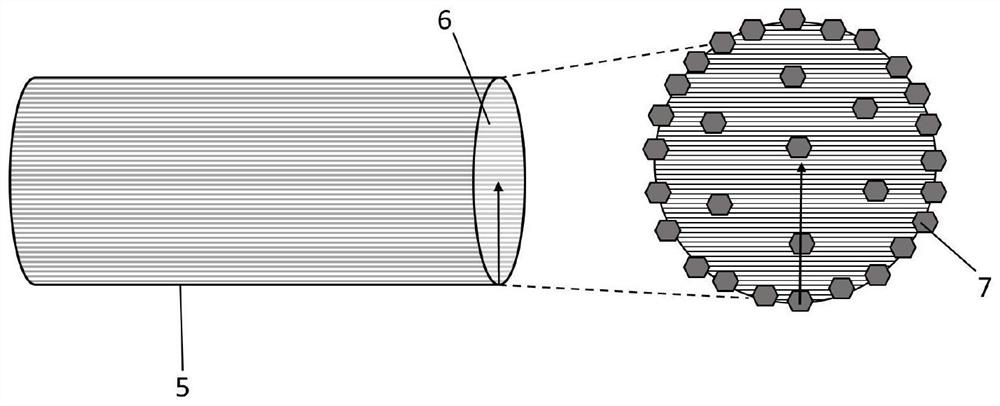

[0092] Wherein the second intermediate layer and the outermost layer of copper-based method for preparing a zeolite fiber layer is as follows:

...

Embodiment 2

[0131] The mask 2 of the present invention includes the following steps:

[0132] The mask includes the outermost layer, the first intermediate layer, the second intermediate layer, and the prosthetic layer; the outermost layer and the second intermediate layer are composed of a copper-based zeolite fiber layer; the first intermediate layer is a hydrophobic fiber layer; the prime layer It is a hydrophilic fiber layer.

[0133] Among them, the preparation method of the copper-based zeolite fiber layer of the outermost layer and the second intermediate layer is as follows:

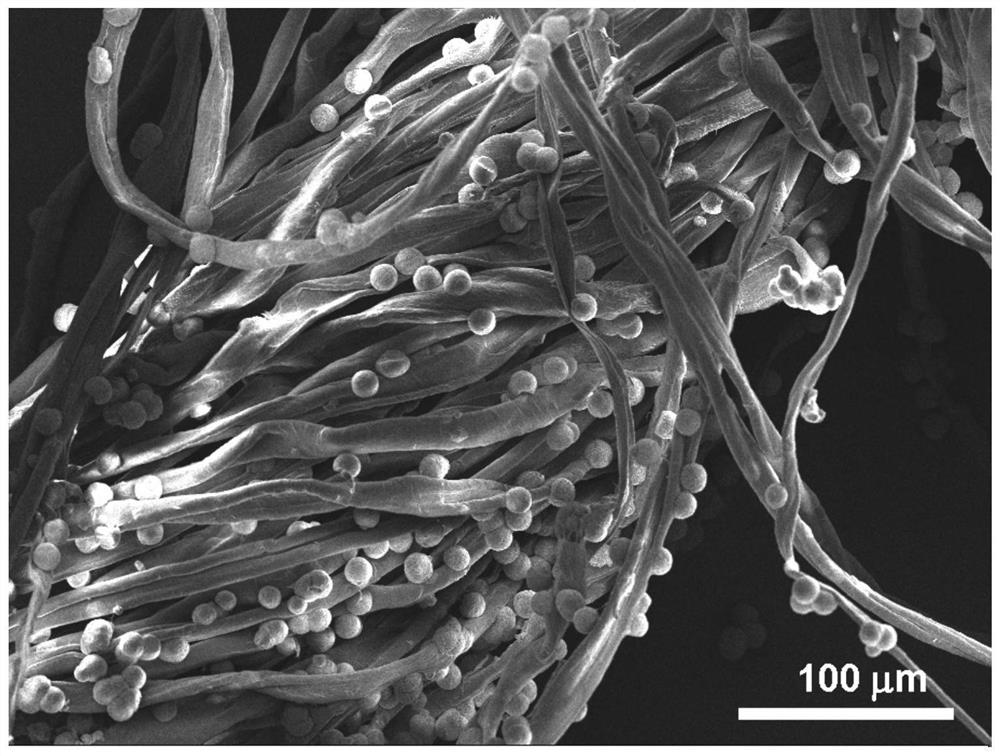

[0134] (1) Preparation of the precursor solution of the zeolite, according to the following mole 8NA 2 O: Al 2 O 3 : 9sio 2 : 180h 2 O Composition of starting materials, synthesized zeolite precursor solution. 60 cotton fiber wound into a fiber line, cotton fiber wrapped around the formed fiber line, the zeolite precursor solution and the fiber line mixed uniform, heat treatment 110 ° C, 36 h, and obtained Y-typ...

Embodiment 3

[0142] The preparation method of the mask 3 of the present invention includes the following steps:

[0143] The mask includes the outermost layer, the first intermediate layer, the second intermediate layer, and the prosthetic layer; the outermost layer and the second intermediate layer are composed of a copper-based zeolite fiber layer; the first intermediate layer is a hydrophobic fiber layer; the prime layer It is a hydrophilic fiber layer.

[0144] Among them, the preparation method of the copper-based zeolite fiber layer of the outermost layer and the second intermediate layer is as follows:

[0145] (1) Preparation of the precursor solution of the zeolite, according to the following mole 8NA 2 O: Al 2 O 3 : 9sio 2 : 180h 2O composition of the starting material, synthetic zeolite precursor solution. 60 will rub the cotton fiber spun fiber strands, wound cotton fibers forming the fiber strand, the zeolite precursor solution and mixed fiber strands, heat treatment 110 ℃, 36h, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com