Prussian blue sodium ion battery positive electrode material and preparation method thereof

A sodium-ion battery and positive electrode material technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of poor rate performance and cycle stability, and achieve the effects of improved rate performance, high crystallinity, and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] The present embodiment provides a kind of preparation method of Prussian blue class sodium ion battery cathode material, comprises the following steps:

[0043]3mmol sodium ferrocyanide decahydrate was dissolved in a mixed solvent composed of 70mL deionized water and 30mL absolute ethanol to obtain precursor solution A;

[0044] Dissolve 6mmol manganese sulfate monohydrate and 6mmol 2,2'-bipyridine in a mixed solvent composed of 70mL deionized water and 30mL absolute ethanol to obtain precursor solution B;

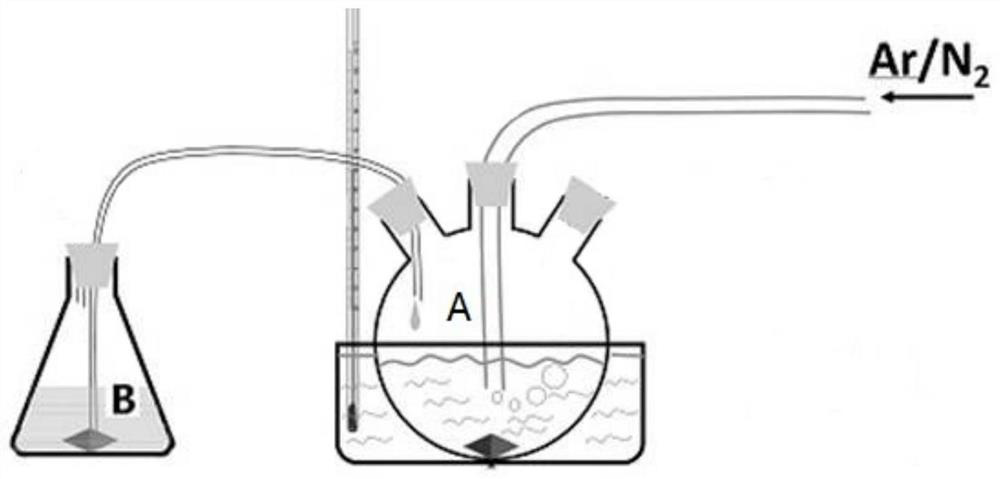

[0045] use figure 1 The device shown is for co-precipitation reaction, wherein container A is equipped with precursor solution A, container B is equipped with precursor solution B, container A and container B are connected through a silica gel conduit, and a peristaltic pump is set on the silica gel conduit to control the drop of precursor solution B Acceleration rate, a magnetic stirrer is installed under the container A to heat and stir the reaction liquid. Feed...

Embodiment 2

[0053] The present embodiment provides a kind of preparation method of Prussian blue class sodium ion battery cathode material, comprises the following steps:

[0054] 3mmol sodium ferrocyanide decahydrate was dissolved in a mixed solvent composed of 60mL deionized water and 40mL acetonitrile to obtain precursor solution A;

[0055] 6mmol nickel dichloride hexahydrate and 9mmol diethylenetriamine were dissolved in a mixed solvent composed of 60mL deionized water and 40mL acetonitrile to obtain precursor solution B;

[0056] use figure 1 The device shown is for co-precipitation reaction, wherein container A is equipped with precursor solution A, container B is equipped with precursor solution B, container A and container B are connected through a silica gel conduit, and a peristaltic pump is set on the silica gel conduit to control the drop of precursor solution B Acceleration rate, a magnetic stirrer is installed under the container A to heat and stir the reaction liquid. Fe...

Embodiment 3

[0064] The present embodiment provides a kind of preparation method of Prussian blue class sodium ion battery cathode material, comprises the following steps:

[0065] 3mmol sodium ferrocyanide decahydrate was dissolved in a mixed solvent composed of 80mL deionized water and 20mL acetic acid to obtain precursor solution A;

[0066] Dissolve 6mmol ferrous acetate and 6mmol 1-10-phenanthroline in a mixed solvent composed of 80mL deionized water and 20mL acetic acid to obtain precursor solution B;

[0067] use figure 1 The device shown is for co-precipitation reaction, wherein container A is equipped with precursor solution A, container B is equipped with precursor solution B, container A and container B are connected through a silica gel conduit, and a peristaltic pump is set on the silica gel conduit to control the drop of precursor solution B Acceleration rate, a magnetic stirrer is installed under the container A to heat and stir the reaction liquid. Argon was introduced in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com