Anatase type titanium dioxide nanocrystalline as well as preparation method and application thereof

An anatase type, titanium dioxide technology, applied in titanium dioxide, chemical instruments and methods, titanium oxide/hydroxide, etc., can solve the problems of limiting titanium dioxide nanocrystals, low reaction rate, etc., and achieves low band gap energy and simple operation. , easy-to-control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0050] The present invention proposes a kind of preparation method of anatase titanium dioxide nanocrystal, it comprises the following steps:

[0051] 1) adding a morphology control agent and a titanium source to the solvent, stirring evenly to obtain a precursor solution; the solvent includes at least acetic acid; the morphology control agent is selected from hexadecyltrimethylammonium bromide and at least one of hydrofluoric acid;

[0052] 2) The precursor solution is subjected to solvothermal reaction at 150° C. to 220° C. for 12 to 72 hours, centrifuged, washed, dried, and ground to obtain anatase titanium dioxide nanocrystals.

[0053] The technical scheme of the present invention uses hydrofluoric acid and / or hexadecyltrimethylammonium bromide as the morphology control agent, uses acetic acid as the solvent or contains acetic acid in the solvent, prepares the precursor solution together with the titanium source, and makes the precursor The solution undergoes solvotherma...

Embodiment 1

[0088] In this embodiment, an anatase titanium dioxide nanocrystal with a cube shape is prepared, and the steps are as follows:

[0089] 1) Disperse 0.24g of cetyltrimethylammonium bromide (CTAB) into 100mL of acetic acid under constant stirring, and stir for 30min;

[0090] 2) Add 4mL tetrabutyl titanate (TBT) dropwise, add 0.24g hydrofluoric acid (HF), stir for 60min, put it into a 200mL stainless steel reactor lined with polytetrafluoroethylene for solvothermal reaction, and the reaction temperature is 180 ℃, reaction time 24h;

[0091] 3) After the solvothermal reaction, the obtained precipitate was centrifuged, washed, dried, and ground to obtain anatase-type TiO with a cube shape. 2 Nanocrystalline.

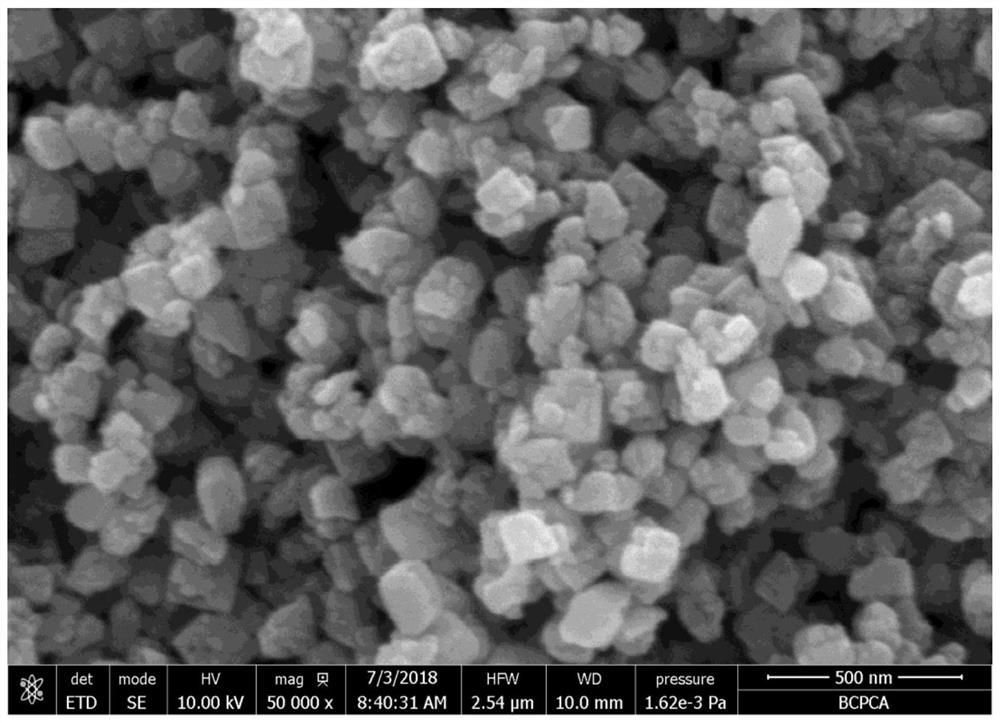

[0092] Titanium dioxide nanocrystals prepared in this embodiment are scanned by electron microscope, and the results are as attached figure 1 shown by the attached figure 1 It can be seen from the SEM image that the TiO of this embodiment 2 Nanocrystals are generally i...

Embodiment 2

[0094] In this embodiment, an anatase titanium dioxide nanocrystal with a cube shape is prepared, and the steps are as follows:

[0095] 1) Disperse 0.24g of cetyltrimethylammonium bromide (CTAB) into 100mL of acetic acid under constant stirring, and stir for 30min;

[0096] 2) Add 4mL tetrabutyl titanate (TBT) dropwise, add 0.48g hydrofluoric acid (HF), stir for 60min, put it into a 200mL stainless steel reactor lined with polytetrafluoroethylene for solvothermal reaction, and the reaction temperature is 180 ℃, reaction time 24h;

[0097] (3) After the solvothermal reaction, the obtained precipitate is centrifuged, washed, dried, and ground to obtain anatase-type TiO with a cube shape. 2 Nanocrystalline.

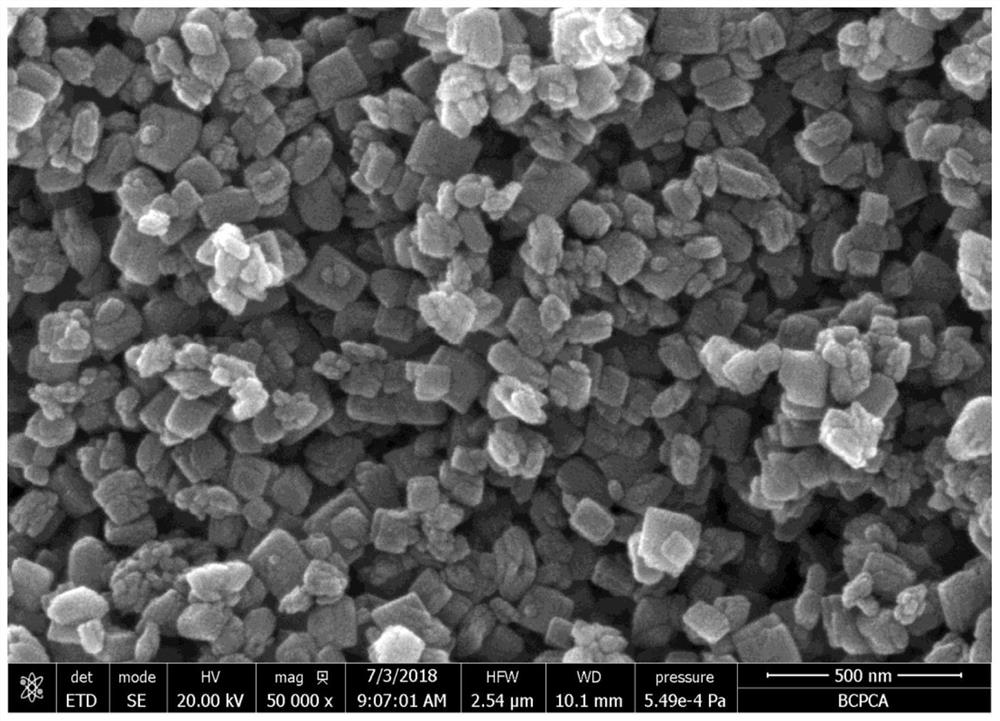

[0098] Titanium dioxide nanocrystals prepared in this embodiment are scanned by electron microscope, and the results are as attached figure 2 shown by the attached figure 2 It can be seen from the SEM image that the TiO of this embodiment 2 Nanocrystals are generally...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com