Preparation method of ternary precursor with controllable structure

A technology of structure control agent and precursor, applied in structural parts, chemical instruments and methods, electrical components, etc., can solve the problem of affecting the crystal structure and sphericity of ternary precursors, affecting electrochemical performance, and increasing manufacturing costs To achieve the effect of promoting the improvement of electrochemical performance, reducing the difficulty of washing, and controlling the degree of compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

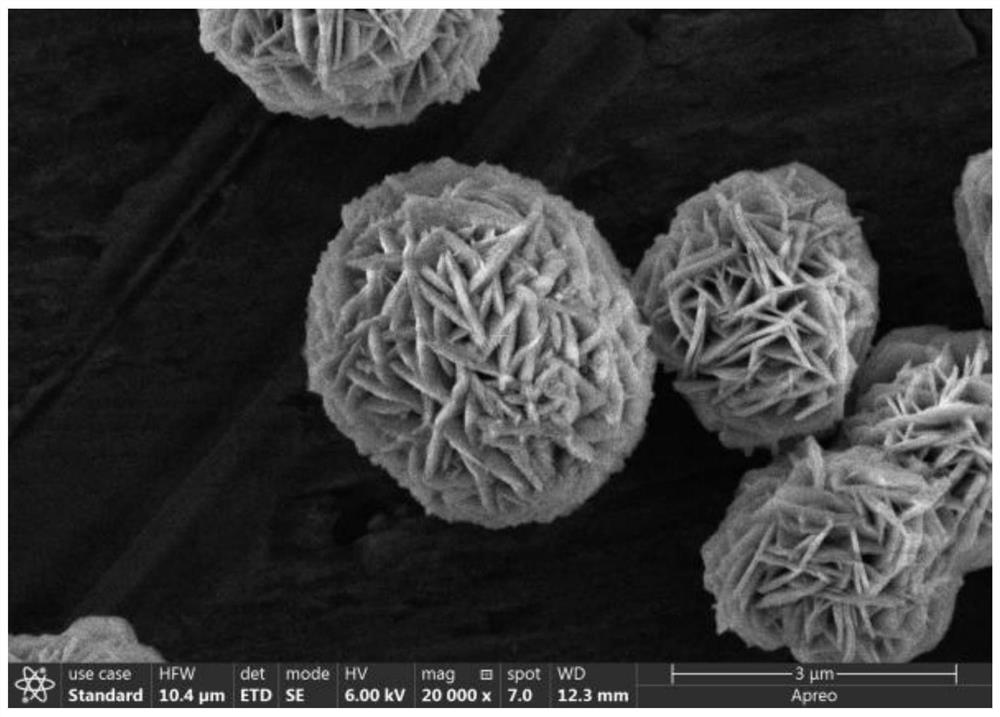

Image

Examples

Embodiment 1

[0033] This embodiment includes the following steps:

[0034] (1) Prepare the reaction kettle bottom liquid according to the concentration of ammonia water at 1mol / L and the pH value at 12.0;

[0035] (2) Prepare ammonium nitrate solution with a concentration of 0.2mol / L as the structure control agent solution;

[0036] (3) Prepare a ternary metal salt solution of nickel: cobalt: manganese = 6:2:2 (molar ratio);

[0037] (4) Inject the ternary metal salt solution, ammonia water, sodium hydroxide solution, and structure control agent solution into the bottom liquid of the reaction kettle, keep the temperature of the reaction kettle at 50°C, and keep the nitrogen atmosphere to react for 5 hours to obtain the reaction slurry;

[0038] (5) Heat the reaction slurry to 90°C to decompose ammonium nitrate to generate nitrogen, and keep stirring for 3 hours;

[0039] (6) The reaction slurry after step (5) was washed with pure water at 60°C for 3h, and then dried in a blast oven at a ...

Embodiment 2

[0042] This embodiment includes the following steps:

[0043] (1) Prepare the reaction bottom solution according to the ammonia concentration of 0.8mol / L and the pH value of 11.5;

[0044] (2) Prepare ammonium nitrate solution with a concentration of 0.1mol / L as the structure control agent solution;

[0045] (3) Prepare a ternary metal salt solution of nickel: cobalt: manganese = 8:1:1 (molar ratio);

[0046] (4) Inject the ternary metal salt solution, ammonia water, sodium hydroxide solution, and structure control agent solution into the reaction bottom liquid, keep the temperature of the reactor at 60°C, and keep the nitrogen atmosphere for 3 hours to obtain the reaction slurry;

[0047] (5) Heat the reaction slurry to 80°C to decompose ammonium nitrate to generate nitrogen, and keep stirring for 1 hour;

[0048] (6) The reaction slurry after step (5) was washed with pure water at 70°C for 2 hours, and then dried in a blast oven at a temperature of 130°C for 12 hours to ob...

Embodiment 3

[0051] This embodiment includes the following steps:

[0052] (1) According to the ammonia concentration of 2mol / L and the pH value of 10.5, prepare the bottom liquid of the reaction kettle;

[0053] (2) Prepare a polyacrylamide (molecular weight <2 million) solution with a concentration of 0.5mol / L as the structure control agent solution;

[0054] (3) Prepare a ternary metal salt solution of nickel: cobalt: manganese = 8:1:1 (molar ratio);

[0055] (4) Inject ternary metal salt solution, ammonia water, sodium hydroxide solution, and structure control agent solution into the reaction bottom liquid, keep the temperature of the reactor at 70°C, and keep the nitrogen atmosphere for 5 hours to obtain the reaction slurry;

[0056] (5) Raise the temperature of the reaction slurry to 90°C to decompose polyacrylamide to generate nitrogen, and keep stirring for 3 hours;

[0057] (5) The reaction slurry after step (5) was washed with pure water at 60°C for 2h, and then dried in a blas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com