Method for preparing cement clinker by utilizing high-magnesium and high-alkali limestone

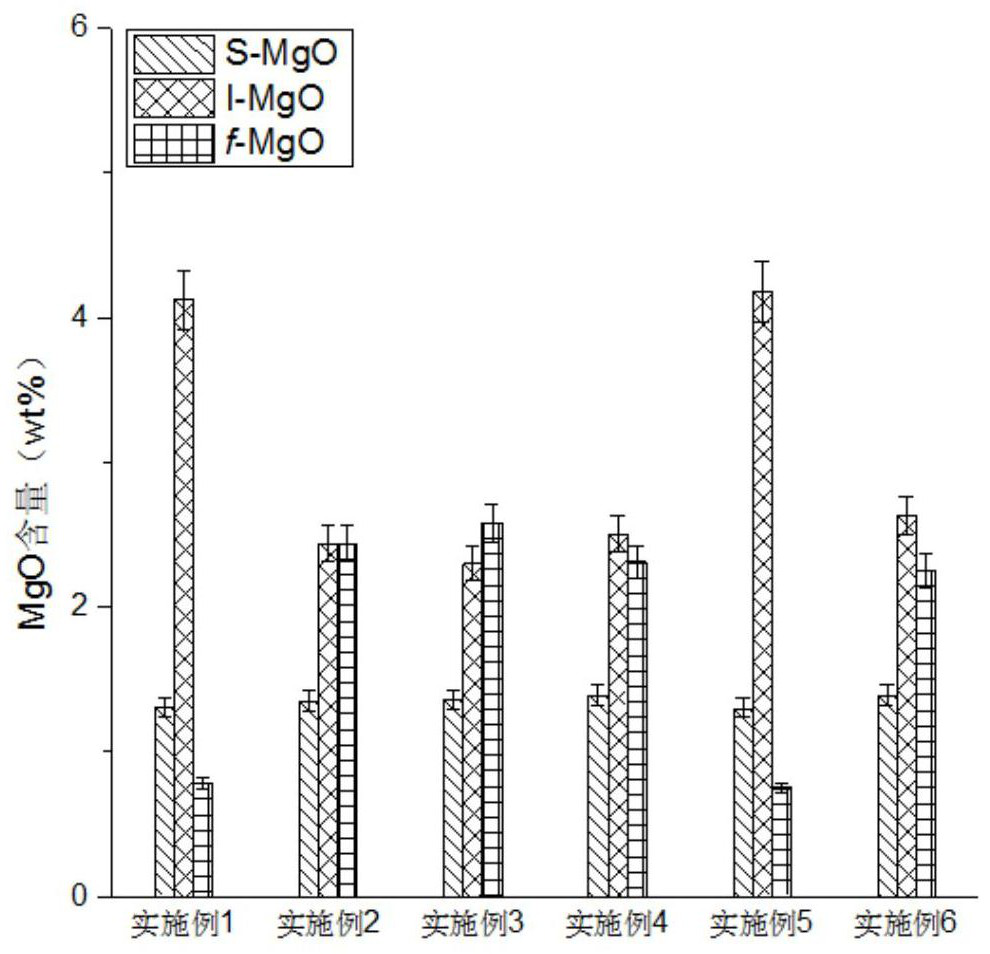

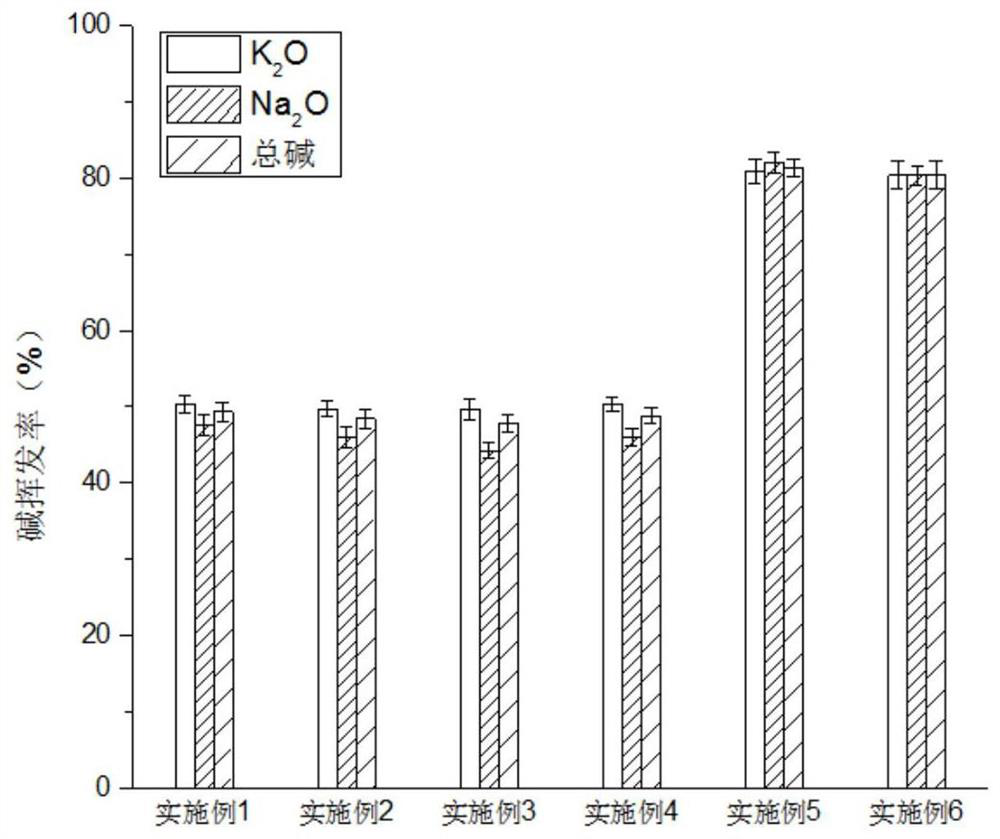

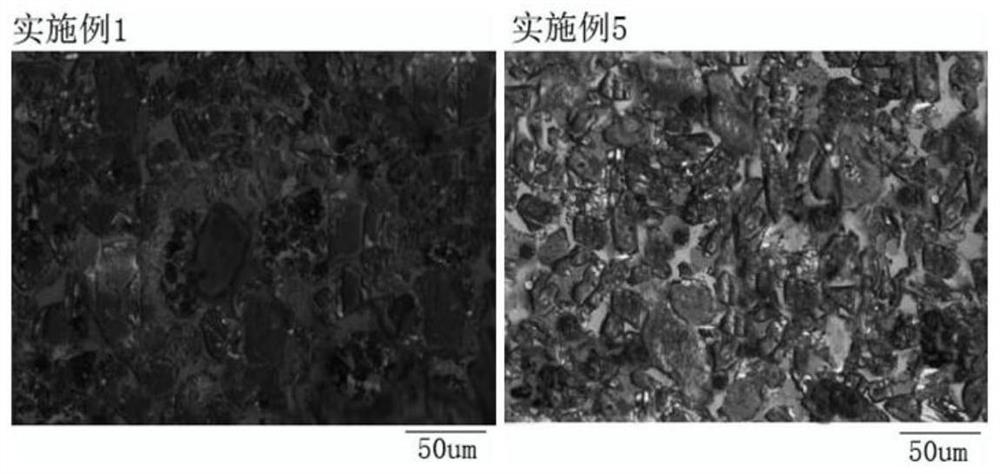

A technology of cement clinker and cement raw material, which is applied in the direction of cement production, etc., which can solve the problems of limited utilization of high-alkali limestone resources, reduction of flexural strength and compressive strength, poor stability of cement cement, etc., and achieve reduction of free MgO content , Promote the perfection of crystallization and increase the effect of solid solution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A method for preparing cement clinker, comprising:

[0033] Table 1 raw material chemical composition (wt%)

[0034]

[0035]

[0036] Table 2 Cement Raw Meal Proportion (wt%)

[0037]

[0038] Table 3 The chemical composition (wt%) and three rate values of the designed clinker

[0039]

[0040] Limestone and sandstone are cleaned and dried, then broken and preliminarily ground with a ball mill, and finally ground with a planetary mill until all of them pass through a 75μm square hole sieve. The slag and coal ash are broken and preliminarily ground with a ball mill, and then ground with a planetary mill until they all pass through a 75μm sieve.

[0041] The various raw material powders after sieving were dried in an oven at 105°C for 12 hours to remove the moisture contained therein, and then the ingredients were prepared according to Table 2. Put the prepared raw material into the planetary mill and use the wet grinding method to homogenize the raw mat...

Embodiment 2

[0044] The addition of potassium humate in the composite mineralizer used in the cement raw meal is 0.10wt%, and the remainder is completely consistent with embodiment 1.

Embodiment 3

[0046]The addition of potassium humate in the composite mineralizer used in the cement raw meal is 0.21wt%, and the remainder is completely consistent with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com