Graphene antibacterial film and air-exhaust-free cube vacuum compression bag

A technology of vacuum compression bag, alkene antibacterial film, applied in the direction of packaging under vacuum / special atmosphere, packaging objects, bags under special gas conditions, etc., can solve environmental pollution, repeated infection of fungi or mold, ordinary plastic film can not kill Various skin diseases and other problems, to achieve the effect of improving the function and safety of use, enhancing film formation and structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The invention provides a graphene antibacterial film, wherein the main materials used include by weight: 45 parts of graphene oxide, 25 parts of polyurethane resin, 15 parts of polyethersulfone resin, 10 parts of polytetrafluoroethylene resin, 8 parts of polyethylene resin, 50 parts of organic solvent, 5 parts of mugwort extract, 2 parts of sodium carboxymethyl cellulose, 1 part of tea polyphenol and 3 parts of cationic nano-silver antibacterial agent;

[0026] The preparation method of graphene antibacterial film is as follows:

[0027] Step 1: Using graphene oxide as a raw material, using a strong oxidant, under the action of stirring, chemically intercalate graphite, shear peeling, dispersing and refining, and sieve to obtain graphite oxide powder, and prepare cationic nano-silver The antibacterial agent and graphene oxide powder are fully mixed evenly and set aside;

[0028] Step 2: Add the mugwort extract into the organic solvent and stir evenly to obtain an organ...

Embodiment 2

[0038] The invention provides a graphene antibacterial film, wherein the main materials used include by weight: 50 parts of graphene oxide, 28 parts of polyurethane resin, 18 parts of polyethersulfone resin, 13 parts of polytetrafluoroethylene resin, 9 parts of polyethylene resin, 55 parts of organic solvent, 6 parts of mugwort extract, 3 parts of sodium carboxymethyl cellulose, 2 parts of tea polyphenols and 5 parts of cationic nano-silver antibacterial agent;

[0039] The preparation method of graphene antibacterial film is as follows:

[0040] Step 1: Using graphene oxide as a raw material, using a strong oxidant, under the action of stirring, chemically intercalate graphite, shear peeling, dispersing and refining, and sieve to obtain graphite oxide powder, and prepare cationic nano-silver The antibacterial agent and graphene oxide powder are fully mixed evenly and set aside;

[0041]Step 2: Add the mugwort extract into the organic solvent and stir evenly to obtain an orga...

Embodiment 3

[0051] The invention provides a graphene antibacterial film, wherein the main materials used include by weight: 52 parts of graphene oxide, 29 parts of polyurethane resin, 19 parts of polyethersulfone resin, 14 parts of polytetrafluoroethylene resin, 10 parts of polyethylene resin, 53 parts of organic solvent, 7 parts of mugwort extract, 4 parts of sodium carboxymethyl cellulose, 2 parts of tea polyphenols and 5 parts of cationic nano silver antibacterial agent;

[0052] The preparation method of graphene antibacterial film is as follows:

[0053] Step 1: Using graphene oxide as a raw material, using a strong oxidant, under the action of stirring, chemically intercalate graphite, shear peeling, dispersing and refining, and sieve to obtain graphite oxide powder, and prepare cationic nano-silver The antibacterial agent and graphene oxide powder are fully mixed evenly and set aside;

[0054] Step 2: Add the mugwort extract into the organic solvent and stir evenly to obtain an or...

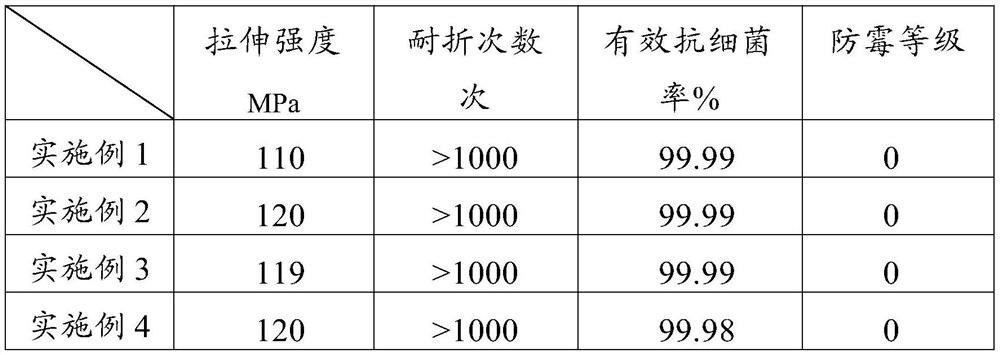

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com