a lithium battery

A lithium battery and electrolyte technology, applied in the direction of battery electrodes, secondary batteries, battery pack components, etc., to achieve the effect of improving the contact surface area, low initial open circuit voltage, and solving the problem of resistance deterioration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

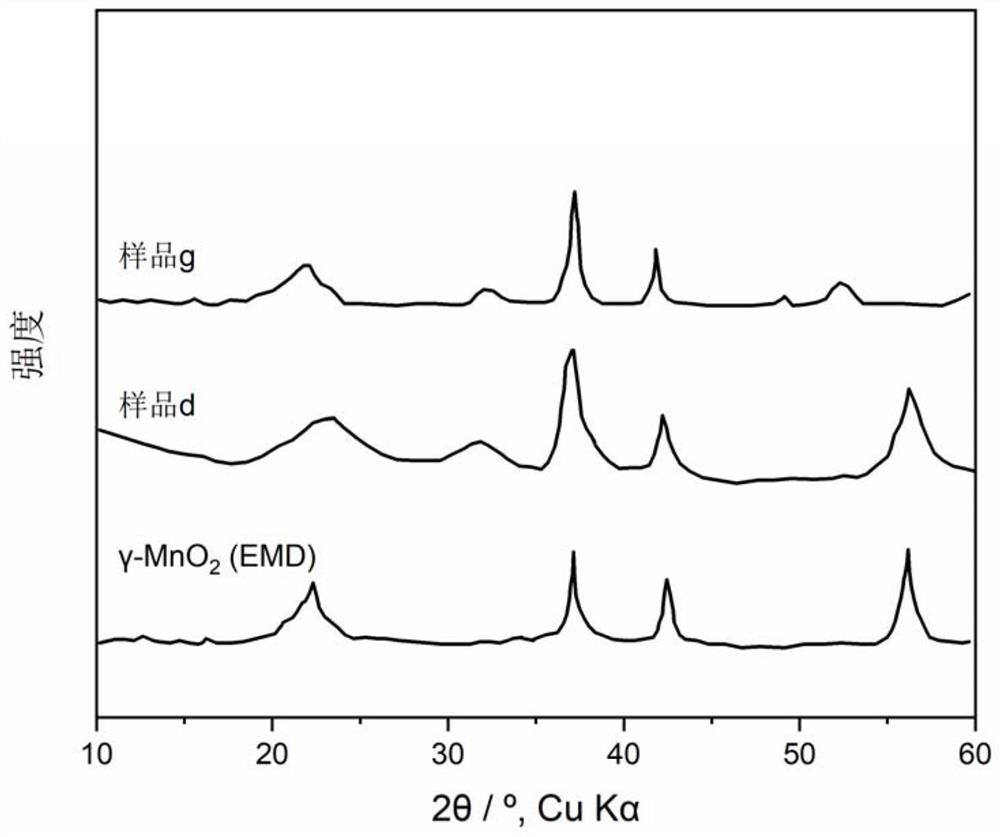

[0054] Preparation of Lithium Manganese Oxide:

[0055] (0) Purification of EMD

[0056] Take 8kg of electrolytic manganese dioxide and add it to 20L of deionized water, keep stirring, slowly add HCl solution with a concentration of 1M until pH=1, keep stirring at room temperature for 24 hours, let stand, remove the supernatant, filter with suction, and then add Deionized water was suction filtered for four times until the pH of the filtrate reached 6, and a filter cake was obtained, which was divided into four uniform portions.

[0057] (1) Preparation method of wet lithium manganese oxide:

[0058] Take four parts of EMD filter cakes of electrolytic manganese dioxide and place them in four parts of 2L deionized water, respectively, to quickly stir to make a suspension, and the stirring time is at least 20 minutes; ·H 2 0), until the pH of the four suspensions increased to 7.5, and continued stirring for at least 30 minutes; one of the suspensions was set aside and continu...

Embodiment 2

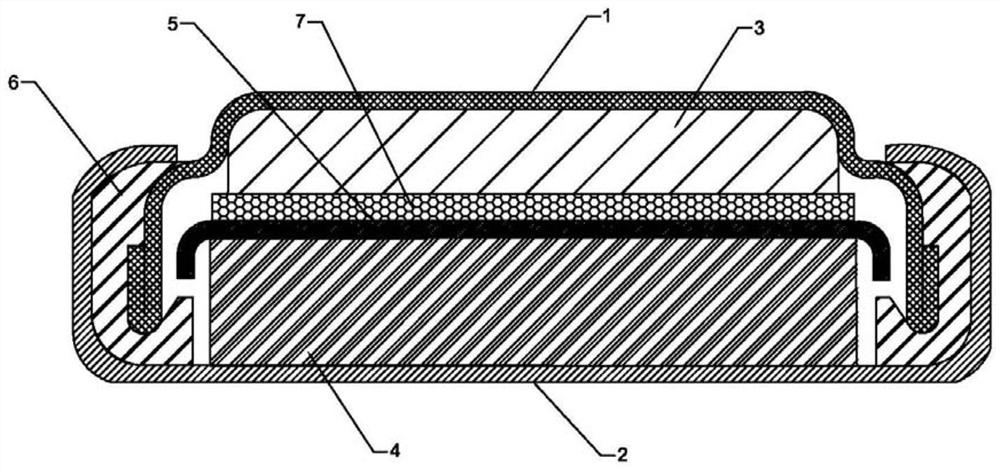

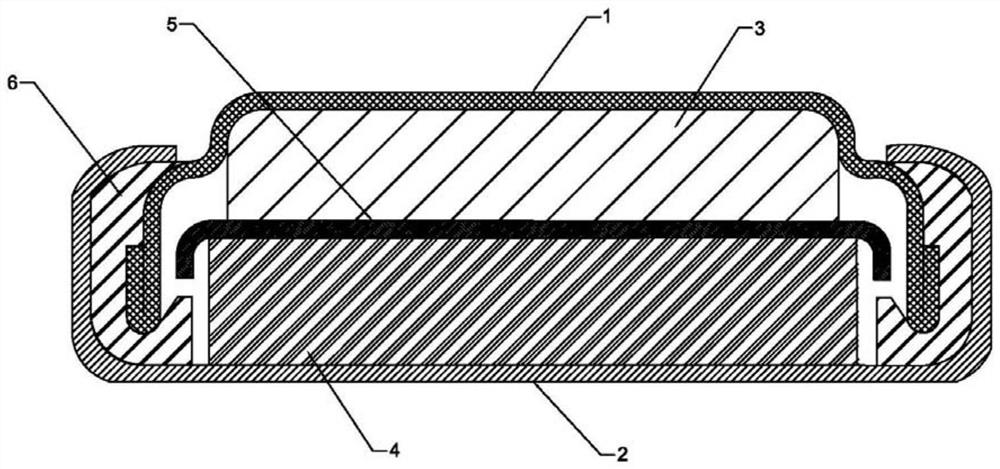

[0064] Button battery production

[0065] (1) Positive electrode active material: samples a, b, c, d, e, f, g, and h in Example 1.

[0066] (2) Positive electrode sheet

[0067] The mass ratio of the positive electrode mixture is shown in Table 1.

[0068] Table 1

[0069]

[0070] The positive electrode mixture was thoroughly mixed and pressed into a disk with a diameter of 15.5 mm and a thickness of 1.5 mm, and then vacuum-dried at 200° C. for 12 hours. A carbon-coated nickel foil with a thickness of 12 μm (the average thickness of the conductive carbon layer is 4 μm) was cut into a circle with a diameter of 16.5, which was laid on the inner flat surface of the positive electrode shell as a positive electrode current collector.

[0071] (3) Negative pole

[0072] A LiAl (Al content: 0.8 wt.%) alloy sheet was pressed onto the flat surface of the negative electrode shell.

[0073] (4) Conductive layer

[0074] The thickness is 0.19mm, the material is PAN-based carbon ...

Embodiment 3

[0091] The difference between the button battery in this embodiment and Embodiment 2 is only the difference in the positive electrode active material in (1). In this embodiment, the positive electrode active material is a mixture of lithium manganese oxide material and graphite fluoride.

[0092] The active material lithium manganese oxide sample c and (CF 1.08 ) n According to the mass ratio of 95:5, the ingredients are ball-milled for 4 hours to obtain the positive electrode active material sample C. In the present embodiment, the battery made by material sample C is marked as battery I, and the discharge test results are shown in Figure 4 .

[0093] Figure 4 It is shown that the lithium manganese oxide material and the graphite fluoride have a good synergistic effect, and there is a low voltage warning level at the end of the battery discharge.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com