High-strength concrete rapid reinforcing and repairing material and preparation method thereof

A technology for repairing materials and concrete, applied in the field of building materials, can solve the problems of inapplicable rapid repair, limited use range, poor aging resistance, etc., and achieve the effect of maintaining volume stability, reducing sensitivity, and preventing agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

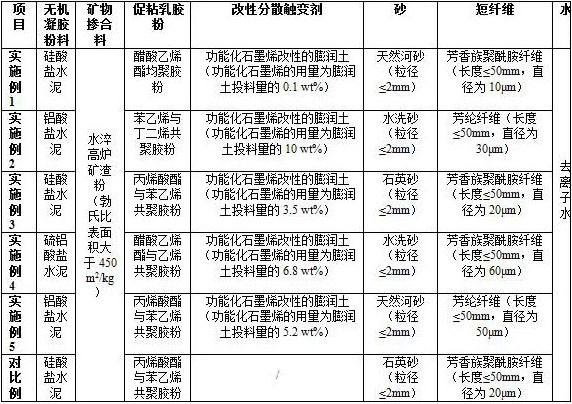

Examples

Embodiment Construction

[0034] After extensive and in-depth research, the inventors found that the introduction of functionalized graphene-modified bentonite as a modified dispersion thixotropic agent in concrete repair materials based on inorganic gelling powder, mineral admixtures and sand can effectively improve the performance of the material. Constructability and sag resistance can also reduce the sensitivity of the material system to temperature, which can reduce the degree of self-shrinkage or expansion of the material system due to temperature changes, which is also beneficial to prolong the service life of the material system itself and ensure the stability of the material system. Repair quality of concrete structures.

[0035] On this basis, the present invention has been accomplished.

[0036] The technical solutions of the present invention will be clearly and completely described below in conjunction with specific embodiments. Apparently, the described embodiments are only some of the em...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com