Method and device for recovering chloropropene and methanol from hydrogen peroxide method epoxy chloropropane process water layer

A technology for epichlorohydrin and chloropropene, which is applied in chemical instruments and methods, preparation of organic compounds, separation/purification of hydroxyl compounds, etc. Up to 99.9% and other problems, to achieve the effect of improving product quality, preventing proliferation and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

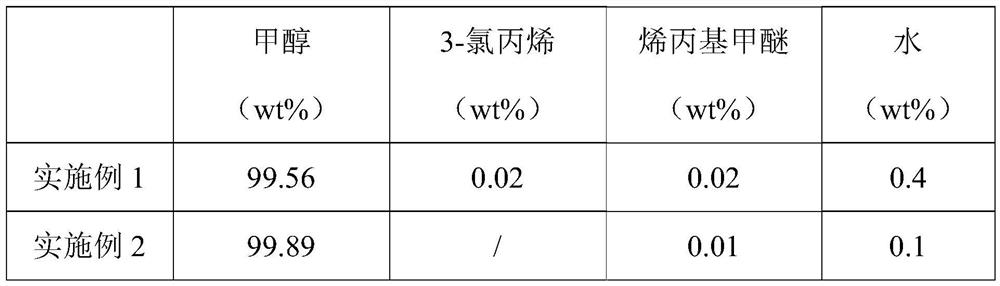

Embodiment 1

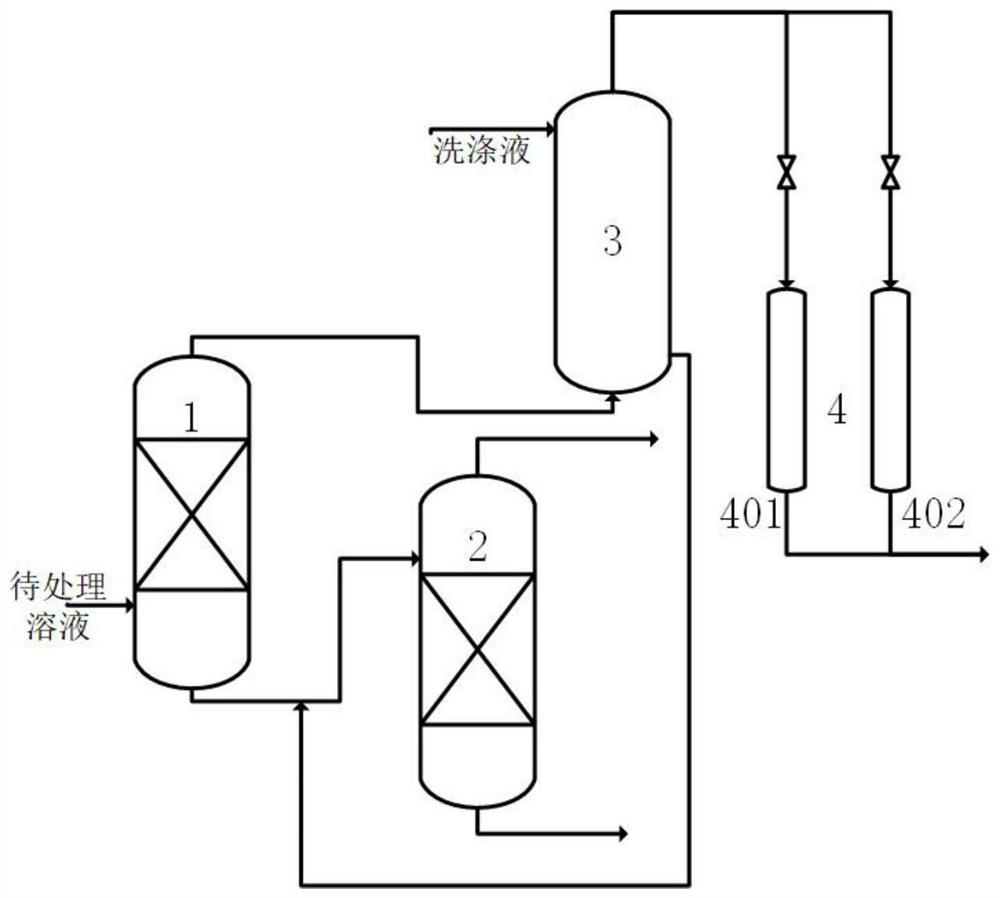

[0102] This embodiment provides a method for reclaiming allyl chloride and methanol from the water layer of the hydrogen peroxide method epichlorohydrin process, such as figure 1 As shown, the device used in the method includes a first rectification unit, a second rectification unit, a washing unit and an adsorption unit 4; the first rectification unit includes a first rectification column 1; the first rectification unit The bottom of the distillation tower 1 is connected with the second rectification unit; the top of the first rectification tower 1 is connected with the washing unit; the washing unit is connected with the adsorption unit 4; the second rectification unit includes the second rectification tower 2 The washing unit includes a washing tower 3; the adsorption unit 4 includes an adsorption device; the adsorption device is two groups of adsorption devices arranged side by side, which are respectively the first adsorption tower 401 and the second adsorption tower 402; ...

Embodiment 2

[0115] This embodiment provides a method for recovering allyl chloride and methanol from the water layer of the hydrogen peroxide method epichlorohydrin process, the method comprising the following steps:

[0116] (1) the solution to be treated is fed from the lower feed port of the first rectifying tower, separated through the first rectification, the tower still obtains the tower still product, and the tower top obtains the tower top product;

[0117] The content of methanol in the solution to be treated is 20wt%, and the content of 3-chloropropene is 0.6wt%; the content of 3-chloropropene in the tower still product is 0.01wt%, and the content of methanol is 19.7wt%; The overhead product contains methanol, 3-chloropropene and allyl methyl ether, the content of allyl methyl ether in the tower overhead product is 0.4wt%, the content of methanol is 40wt%, and the content of 3-chloropropene is 59.6 wt%;

[0118] The first rectification separation is atmospheric rectification, t...

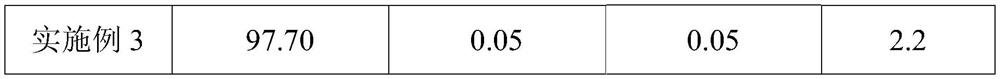

Embodiment 3

[0127] This embodiment provides a method for recovering allyl chloride and methanol from the water layer of the hydrogen peroxide method epichlorohydrin process, the method comprising the following steps:

[0128] (1) the solution to be treated is fed from the lower feed port of the first rectifying tower, separated through the first rectification, the tower still obtains the tower still product, and the tower top obtains the tower top product;

[0129] The content of methanol in the solution to be treated is 20wt%, and the content of 3-chloropropene is 0.6wt%; the content of 3-chloropropene in the tower still product is 0.06wt%, and the content of methanol is 19.8wt%; The overhead product contains methanol, 3-chloropropene and allyl methyl ether, the content of allyl methyl ether in the tower overhead product is 0.6wt%, the content of methanol is 35.0wt%, and the content of 3-chloropropene is 64.4wt%;

[0130] The first rectification separation is atmospheric rectification, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com